Horizontal well cementation segmented multi-cluster volume fracturing technology

A volume fracturing and well cementing cluster technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of inability to fracturing, low construction efficiency, and inability to fully transform reservoirs, etc. Achieve the effect of reducing processing, increasing single well production, and achieving effective development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

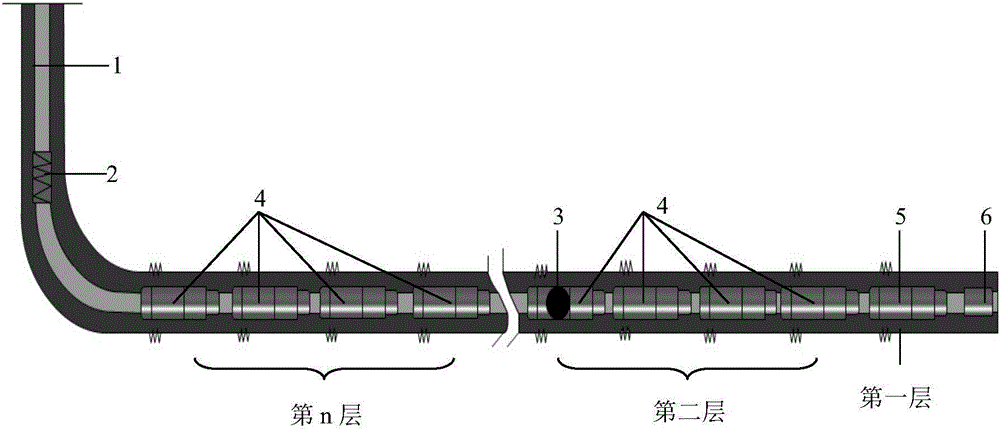

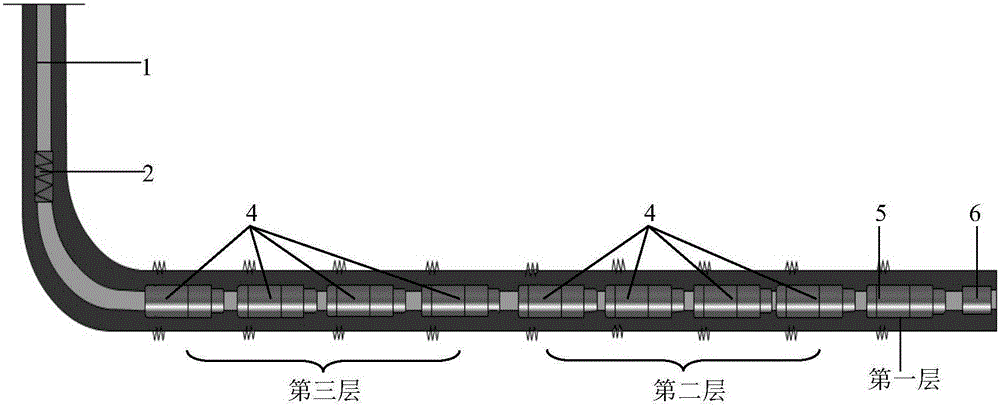

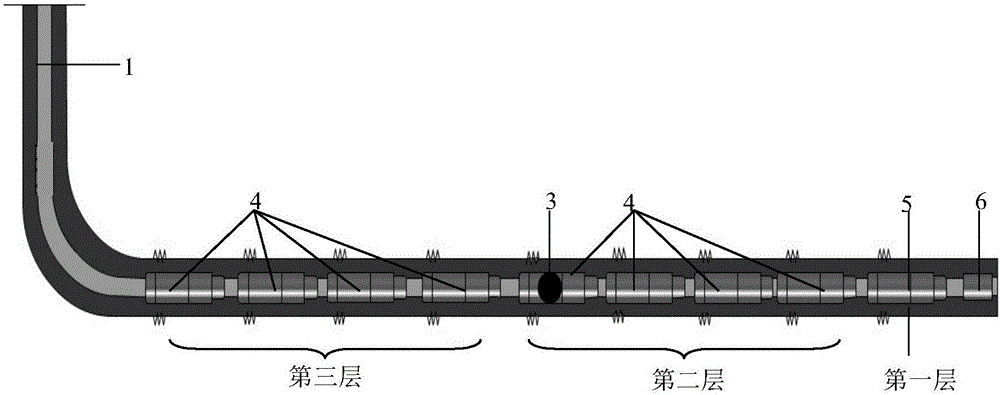

[0013] Detailed ways: Below in conjunction with accompanying drawing, the present invention is described further: the present invention is realized by the following devices: the device consists of casing 1, scraper tool 2, ball 3, horizontal well cementing cluster sliding sleeve 4, pressure sliding sleeve 5 and bumper seat 6; wherein the upper end of the bottommost bumper seat 6 is sequentially connected to the pressure sliding sleeve 5 and four groups of multi-group horizontal well cementing cluster sliding sleeves 4, and the bottom of the casing 1 is sequentially connected to the scraper tool 2. Horizontal well cementing cluster sliding sleeve 4; a horizontal well cementing staged multi-cluster volume fracturing process is realized through the following steps:

[0014] a. First, run the connected horizontal well cementing cluster sliding sleeve 4, pressure sliding sleeve 5, and bumper seat 6 into the well along with the casing 1;

[0015] b. Go down to the design depth, ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com