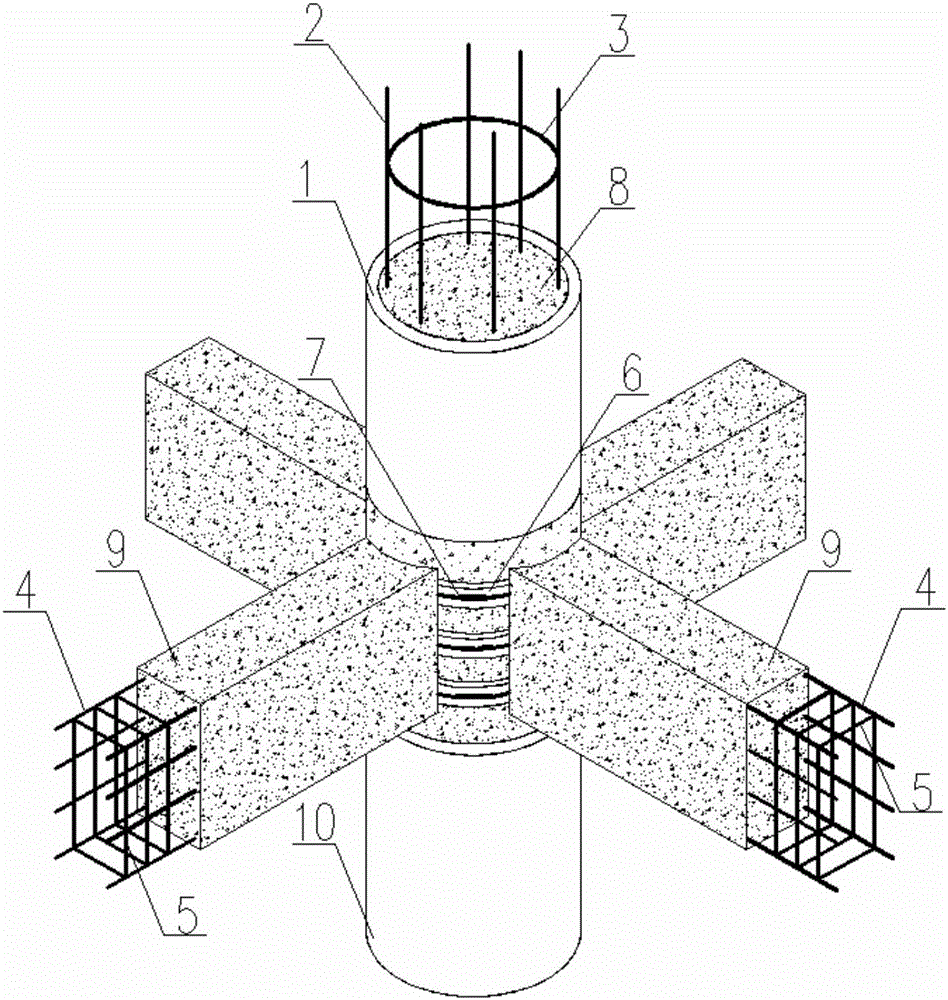

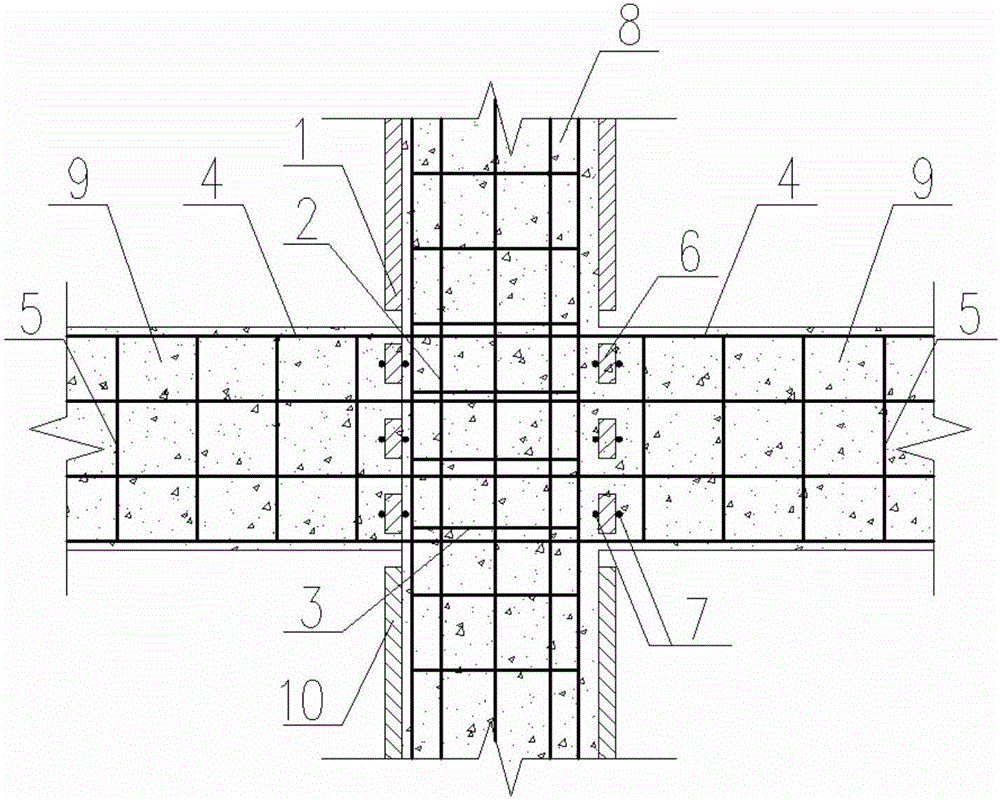

Structure of reinforced circular steel tube confined concrete column-beam joint

A technology for constraining concrete and reinforced concrete beams, applied in the direction of building structure, construction, etc., can solve problems such as failure, difficulty in meeting strong joints, weak components, etc., to improve bearing capacity and deformation performance, avoid local instability, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046]Two reinforced concrete beams perpendicular to each other, the intersection of the steel pipe confined concrete column and the two reinforced concrete beams is the node. The diameters of the upper column steel pipe 1 , the lower column steel pipe 10 and the steel ring 6 in the node area are all 500 mm, and the wall thickness is 8 mm. The heights of the steel rings 6 in the three node areas from top to bottom are 50mm, 200mm and 50mm respectively. Both reinforced concrete beams are 250mm wide and 500mm high. Steel ring 6 in the node area, steel pipe 1 for the upper column body and steel pipe 10 for the lower column body are all made of Q345 steel, and the strength grade of the column concrete is C50.

[0047] The reinforced concrete beam is composed of beam longitudinal bars 4 , beam stirrups 5 and beam concrete 9 . The beam longitudinal bars 4 are distributed as two HRB400 steel bars with a diameter of 14mm in the upper part, two HRB400 steel bars with a diameter of 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com