Micro-electrolytic filling material and preparation method thereof

A technology of micro-electrolysis and iron filings, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Battery and other problems, to achieve the effect of good adsorption and catalytic carrier effect, strong activity, and reduced operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

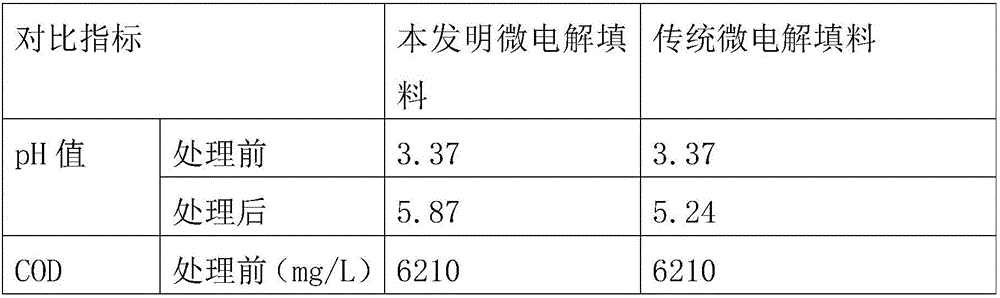

Examples

Embodiment 1

[0051] A micro-electrolytic filler, the content of each component is as follows (wt%): iron powder: 60; iron filings: 15; purple sand: 2; borax: 2; bentonite: 5; activated carbon powder: 6; 0.1; corn starch: 0.2; sodium carboxymethylcellulose: 0.1. The preparation method comprises the following steps (1) screening of raw materials: removing impurities and screening of various raw materials as required; (2) mixing of raw materials: mixing the iron powder, iron filings, purple sand, borax, bentonite, activated carbon powder, hydrogen Sodium oxide, zeolite, corn starch, and sodium carboxymethyl cellulose were mixed uniformly by a mechanical mixer according to the ratio, and the stirring time was 60 minutes; (3) Film forming: After adding water, stirring and aging for 20 minutes, the mixture was mechanically extruded. A shaped filler with a diameter of 80 mm and a height of 60 mm was obtained, and a wet filler body was made through demoulding; (4) Drying and sintering: After natur...

Embodiment 2

[0056]A micro-electrolytic filler, the content of each component is as follows (wt%): iron powder: 60; iron filings: 15; purple sand: 3; borax: 1; bentonite: 8; activated carbon powder: 8; sodium hydroxide: 1; 0.5; corn starch: 0.5; sodium carboxymethylcellulose: 0.8. The preparation method comprises the following steps (1) screening of raw materials: removing impurities and screening of various raw materials as required; (2) mixing of raw materials: mixing the iron powder, iron filings, purple sand, borax, bentonite, activated carbon powder, hydrogen Sodium oxide, zeolite, corn starch, and sodium carboxymethyl cellulose were mixed uniformly by a mechanical mixer according to the ratio, and the stirring time was 60 minutes; (3) Film forming: After adding water, stirring and aging for 20 minutes, the mixture was mechanically extruded. A shaped filler with a diameter of 120mm and a height of 100mm was obtained, and a wet filler body was made through demoulding; (4) Drying and si...

Embodiment 3

[0060] A micro-electrolytic filler, the content of each component is as follows (wt%): iron powder: 64; iron filings: 16; purple sand: 2; borax: 2.5; bentonite: 5; activated carbon powder: 5; 0.4; corn starch: 0.3; sodium carboxymethylcellulose: 0.7. The preparation method comprises the following steps (1) screening of raw materials: removing impurities and screening of various raw materials as required; (2) mixing of raw materials: mixing the iron powder, iron filings, purple sand, borax, bentonite, activated carbon powder, hydrogen Sodium oxide, zeolite, corn starch, and sodium carboxymethyl cellulose were mixed uniformly by a mechanical mixer according to the ratio, and the mixing time was 60 minutes; (3) Film forming: After adding water, stirring and aging for 25 minutes, the mixture was mechanically extruded. A shaped filler with a diameter of 90mm and a height of 80mm was obtained, and a wet filler body was made through demoulding; (4) Drying and sintering: after natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com