Pressure controller for injection molding machine

An injection molding machine and pressure control technology, which is applied in the field of pressure control devices, can solve the problems of cost increase and achieve the effect of preventing stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

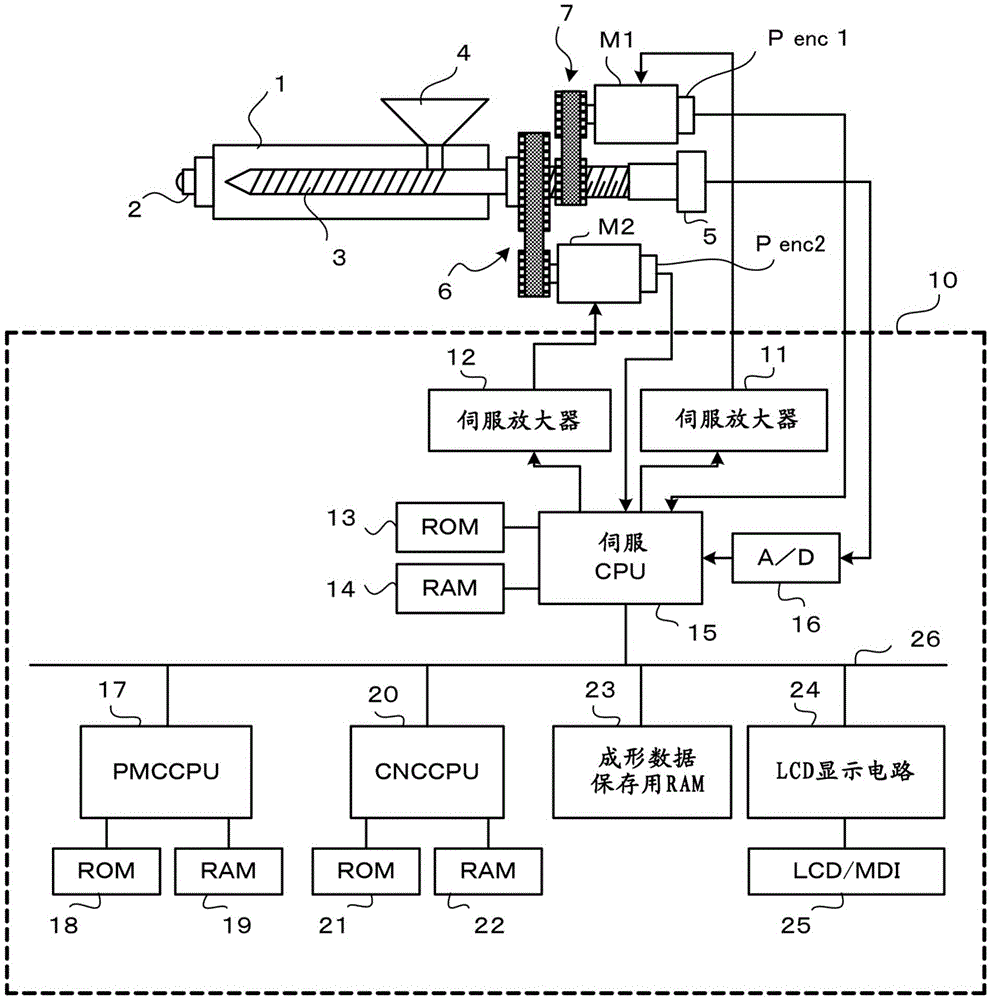

[0035] below, with Figure 1 Embodiments of the present invention will be described together.

[0036] figure 1 It is a schematic configuration diagram of an injection molding machine and a control device for controlling the injection molding machine. A nozzle 2 is attached to the front end of the cylinder 1 into which the screw 3 is inserted, and a hopper 4 for supplying resin pellets to the cylinder 1 is attached to the side of the rear end of the cylinder 1 . The screw 3 is driven in the axial direction by the injection servo motor M1, the transmission mechanism, and the conversion mechanism 7 that converts the rotational motion of the bolt / nut etc. into a linear motion as a driving unit for driving the screw 3 in the axial direction. Injection and back pressure control. In addition, the screw 3 is rotationally driven by a transmission mechanism 6 composed of a servo motor M2 as a rotational drive means for rotating the screw 3 , a belt, a pulley, and the like.

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com