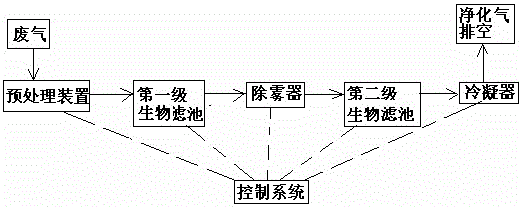

Two-stage biological process waste gas treatment system

A technology of waste gas treatment and biological method, which is applied in the direction of separation method, air quality improvement, chemical instrument and method, etc., can solve the problems of simple function and incomplete treatment of various different gases, etc., and achieves small wind resistance of equipment and high degree of automation of equipment , the effect of good structural stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

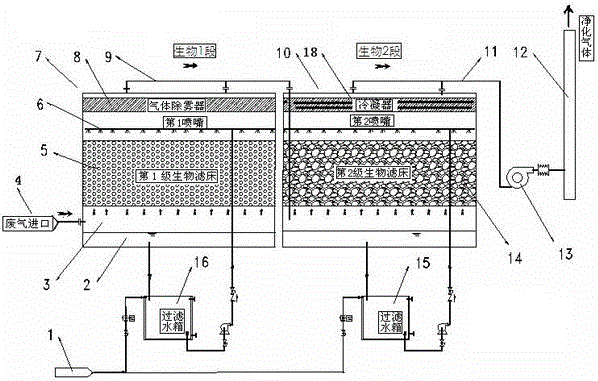

[0029] Such as figure 2 The shown two-stage biological waste gas treatment system has a first-stage biofilter 7 and a second-stage biofilter 10 . There is a first-stage biofilter bed layer 5 in the first-stage biofilter 7, and there are active biological strains in the first-stage biofilter bed layer 5, and wherein the thiophage species are the most active; the second-stage biofilter 10 There is a second-stage biological filter bed layer 14 in the middle, and the second-stage biological filter bed layer 14 has active biological strains, wherein the non-sulfur bacterial strains are more active.

[0030] Exhaust gas enters from the first-stage biofilter 7, is filtered, degraded or oxidized by the first-stage biofilter bed layer 5, and then flows out from the first-stage gas outlet pipeline, then flows through the second-stage biofilter 10, and passes through the second-stage biofilter 10. The first-stage biological filter bed layer 14 is filtered, degraded or oxidized and flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com