Printed circuit board and fully-additive manufacturing method therefor

A printed circuit board and manufacturing method technology, applied in the electronic field, can solve the problems of high cost and low production efficiency of printed circuit boards, and achieve the effects of high reliability, high production efficiency and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

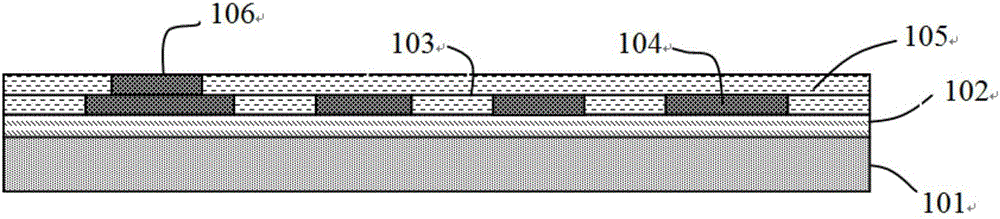

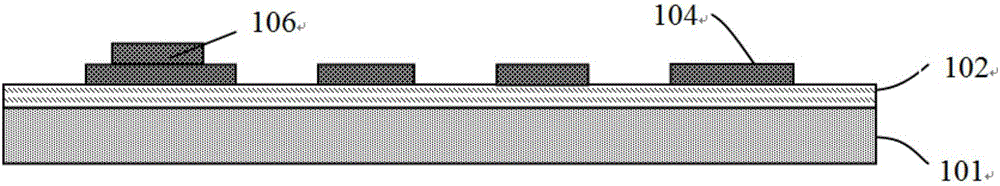

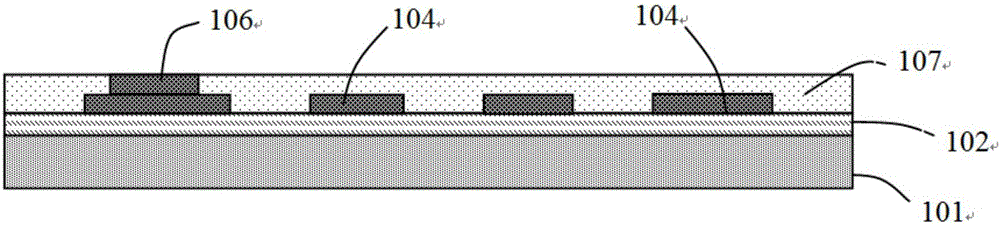

[0041] Embodiment: a kind of printed circuit board, see Figure 6 , the printed circuit board is mainly composed of a plurality of laminated first structures and second structures, the first structure and the second structure are distributed at intervals, and the first structure and the second structure are formed by hot pressing, and the The first structure is mainly composed of a circuit carrier. The circuit carrier is embedded with a conductive bump 106 and a circuit layer 104. The conductive bump 106 is electroplated on the circuit layer 104. The second structure is mainly composed of an insulating dielectric plate. The insulating medium plate is embedded with a conductive block 202, and the circuit layers on the two adjacent first structures are connected through the conductive block. The circuit carrier is a resin plate 107; the insulating medium plate is a prepreg 201, and the prepreg 201 As an interlayer bonding structure, the interconnection reliability of the interla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com