Full-bridge LLC resonant converter and synchronous rectification driving method thereof

A resonant converter and synchronous drive technology, applied in the direction of converting DC power input to DC power output, instruments, and adjusting electrical variables, etc., can solve the problems of affecting efficiency, circulating current, and off time lag, so as to save the detection circuit, Simple driving method and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

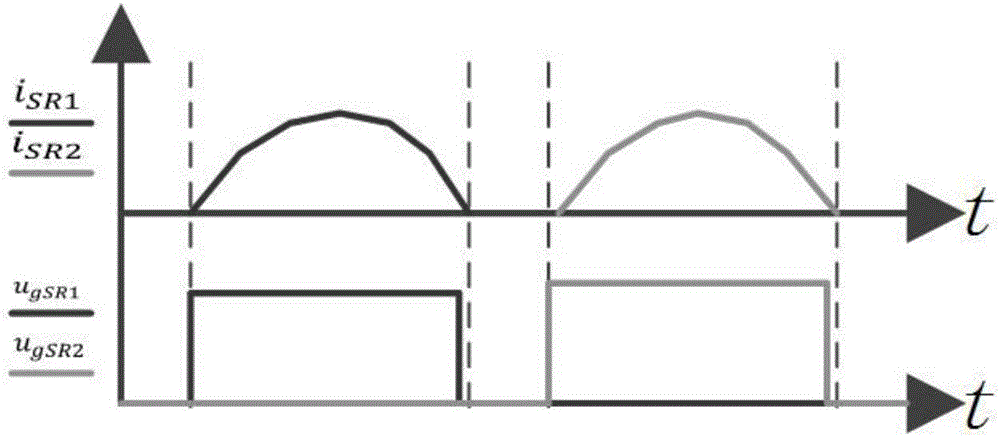

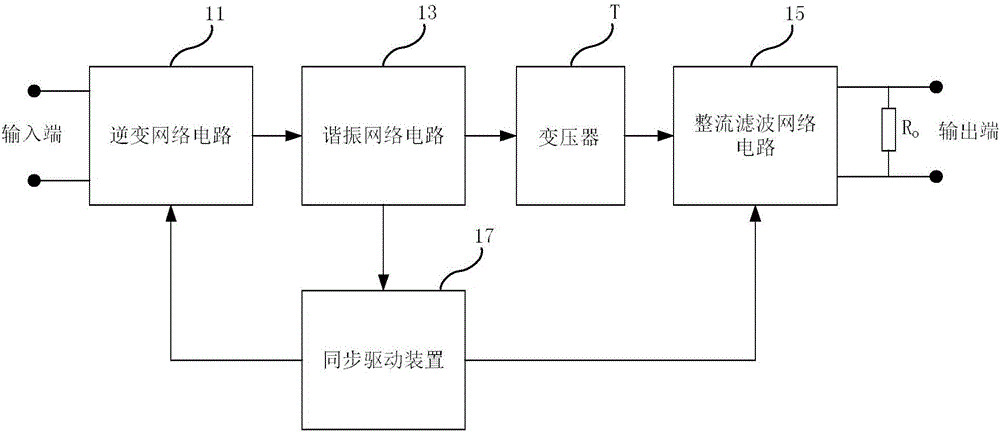

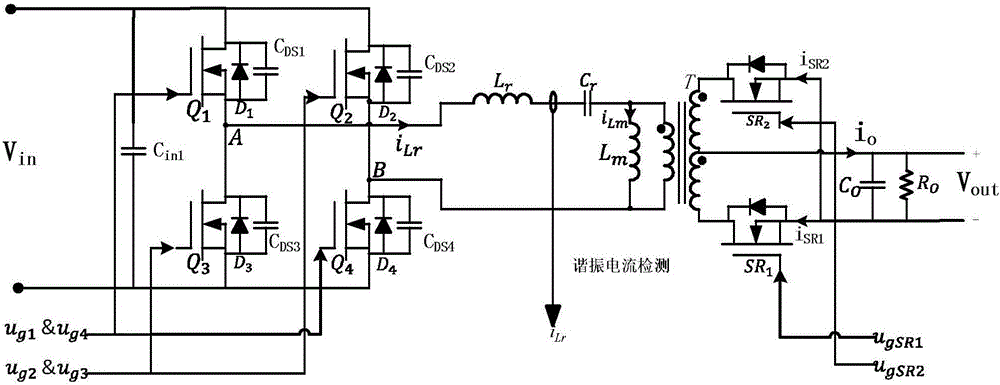

[0049] Please also see figure 2 and image 3 , figure 2 It is a schematic diagram of a circuit module of a full-bridge LLC resonant converter according to an embodiment of the present invention; image 3 It is a circuit structure diagram of a full-bridge LLC resonant converter according to an embodiment of the present invention. The full-bridge LLC resonant converter includes an input terminal (V in ), inverter network circuit (11), resonant network circuit (13), transformer (T), rectifier filter network circuit (15), output load (R O ) and the output (V out ), also includes a synchronous drive (17). specifically:

[0050] The synchronous drive device (17) includes a resonant frequency detection module (171), a synchronous drive module (173), and an isolation drive module (175); wherein, the resonant frequency detection module (171) is based on the resonant network circuit ( 13) The extracted resonant current (i Lr ) to calculate the resonance period (t r ); the syn...

Embodiment 2

[0060] Please also see Figure 4 and Figure 5 , Figure 4 It is a flowchart of a synchronous rectification digital driving method according to an embodiment of the present invention; Figure 5 It is a schematic diagram of the working principle of a synchronous rectification digital drive device according to an embodiment of the present invention. The method is applied in a full-bridge LLC resonant converter, and the full-bridge LLC resonant converter includes an inverter network circuit (11), a resonant network circuit (13), a transformer (T), and a rectifying and filtering network circuit (15), wherein , the method includes the steps of:

[0061] Step 1, according to the resonant current (i Lr ) to calculate the resonance period (t r );

[0062] Step 2. Compare the switching frequency (f s ) and the resonant period (t r ) converted resonant frequency (f r ) to obtain the comparison result, and determine the synchronous rectification turn-off time (t off );

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com