Technology for directly printing pattern on plastic electroplated key cap

A technology for printing patterns and keycaps, applied in printing, printing devices, electrical components, etc., can solve problems such as poor wear resistance, poor surface hardness, and unstable dimensions, and achieve good surface hardness, easy processing, and stable dimensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

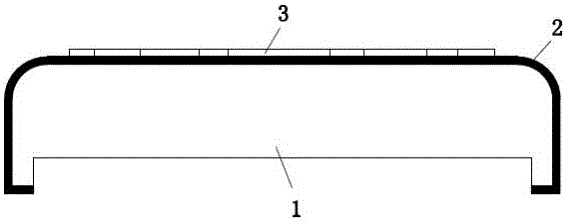

Image

Examples

Embodiment 1

[0034] A kind of process of directly printing patterns on the plastic water-plated keycap of the present embodiment, it comprises the following steps:

[0035] Step 1, injection molding keycaps: use the keycap injection mold to inject conductive ASB plastic material into keycaps; in this embodiment, the injection molding conditions are: injection molding temperature is 240°C, injection pressure is 80kgf / cm 2 , the injection time is 20s;

[0036] Step 2, coating the keycap with insulating oil: apply washable insulating oil on the bottom of the keycap in step 1, and after baking at 60°C for 10 minutes, a washable insulating oil layer is formed on the bottom of the keycap; among them, the insulating The oil is provided by Shenzhen Wanjiayuan Refining Technology Co., Ltd., and its model is 3389-09 insulating oil;

[0037] Step 3, electroplating a metal film layer: using an electroplating process to electroplate a metal film layer on the surface of the keycap coated with insulatin...

Embodiment 2

[0042] A kind of process of directly printing patterns on the plastic water-plated keycap of the present embodiment, it comprises the following steps:

[0043] Step 1, injection molding keycaps: use the keycap injection mold to inject conductive ASB plastic material into keycaps; in this embodiment, the injection molding conditions are: the injection temperature is 220°C, and the injection pressure is 70kgf / cm 2 , the injection time is 25s;

[0044] Step 2, coating the keycap with insulating oil: apply washable insulating oil on the bottom of the keycap in step 1, and after baking at 50°C for 12 minutes, a washable insulating oil layer is formed on the bottom of the keycap; among them, the insulating The oil is provided by Shenzhen Wanjiayuan Refining Technology Co., Ltd., and its model is 3389-09 insulating oil;

[0045] Step 3, electroplating a metal film layer: using an electroplating process to electroplate a metal film layer on the surface of the keycap coated with insulat...

Embodiment 3

[0050] A kind of process of directly printing patterns on the plastic water-plated keycap of the present embodiment, it comprises the following steps:

[0051] Step 1, injection molding keycaps: use the keycap injection mold to inject conductive ASB plastic material into keycaps; in this embodiment, the injection molding conditions are: injection molding temperature is 260°C, injection pressure is 90kgf / cm 2 , the injection time is 15s;

[0052] Step 2, coating the keycap with insulating oil: apply washable insulating oil on the bottom of the keycap in step 1, and bake at 70°C for 8 minutes to form a washable insulating oil layer on the bottom of the keycap; among them, the insulating The oil is provided by Shenzhen Wanjiayuan Refining Technology Co., Ltd., and its model is 3389-09 insulating oil;

[0053] Step 3, electroplating a metal film layer: using an electroplating process to electroplate a metal film layer on the surface of the keycap coated with insulating oil at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com