Mixed fatigue reliability optimization method aiming at composite material laminated plate

A composite material and optimization method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limiting the practical process of theoretical engineering, and achieve the effect of improving the accuracy and rationality of the solution and reducing the dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

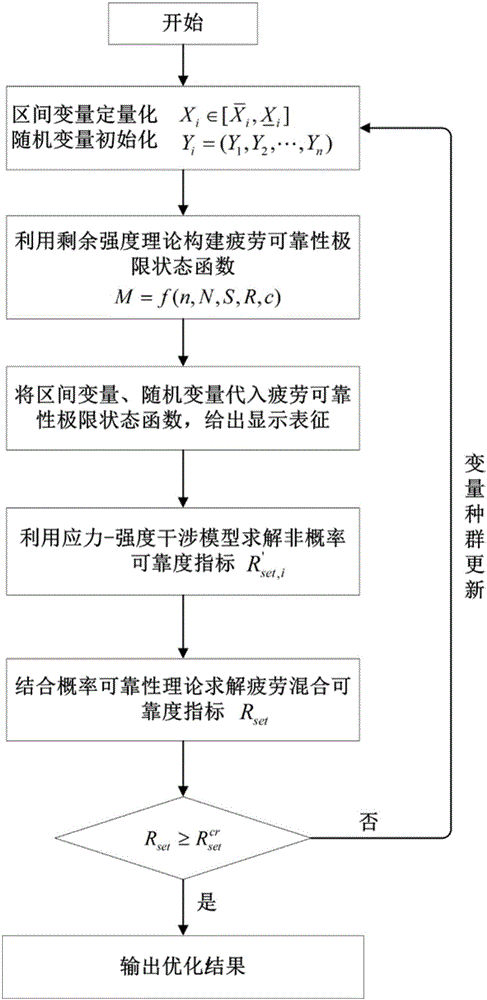

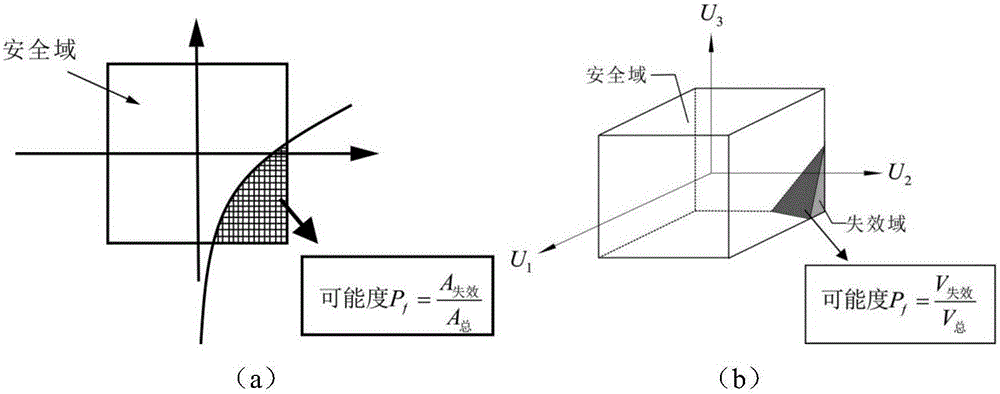

Method used

Image

Examples

Embodiment

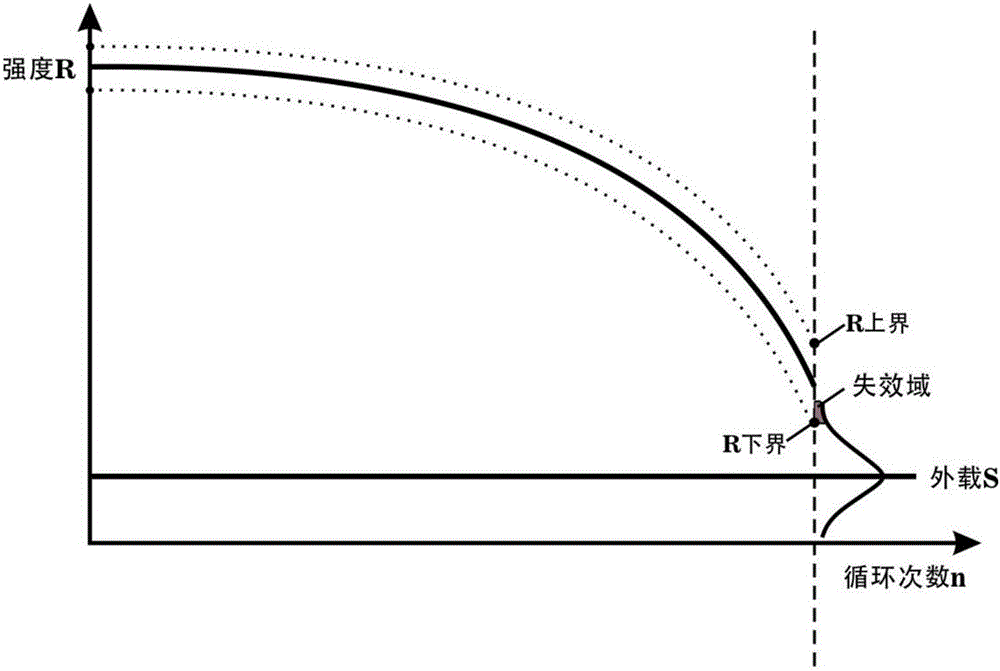

[0078] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at such as Figure 5 The proposed laminate structure shown is subjected to a fatigue hybrid reliability solution based on residual strength theory. The laminated plate structure bears cyclic load S∈N(317,12.6), fatigue life N=118000, the static strength of the laminated plate structure R∈[876,896], plate length l=100mm, plate width w=40mm, plate thickness t= 5mm, to investigate the fatigue reliability when the number of cycles n=70000 under working conditions, considering the geometric dimensions and loading conditions, using the established method for solving the mixed fatigue reliability, the mixed fatigue reliability can be calculated as 0.9786.

[0079] According to the desired mixed fatigue reliability index, with the allowable reliability as the constraint, the optimal design is carried out, and finally when the allowable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com