Capsule type pouring and filling method and structure for large-size karst pile foundation construction

A filling method and large-volume technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of not improving the bearing capacity of the pile foundation more significantly, the loss of filling materials, and the lack of a force-transmitting layer, etc., to achieve good absorption and dispersion, Good bearing capacity and saving filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below according to accompanying drawing:

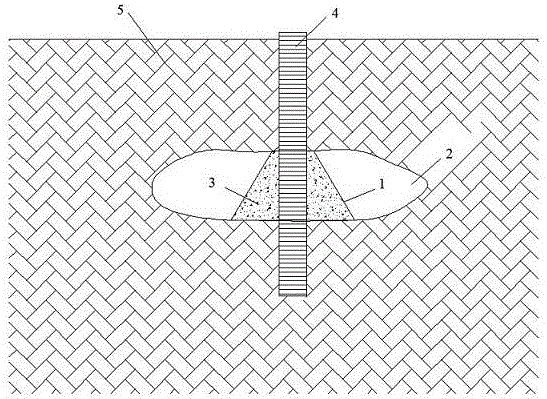

[0028] according to figure 1 , figure 2 It can be seen that a capsule grouting filling method for large-volume karst pile foundation construction includes the following steps:

[0029] Step 1: There are generally obvious differences in physical properties such as density, velocity, and electrical properties between karst 2 and formation 5. Through advanced geological exploration, use resistivity method, microgravity method, electromagnetic wave method, seismic wave method, transient Electromagnetic method, geological radar and other geophysical methods are used to find out the distribution range, burial depth, development and approximate size of karst 2;

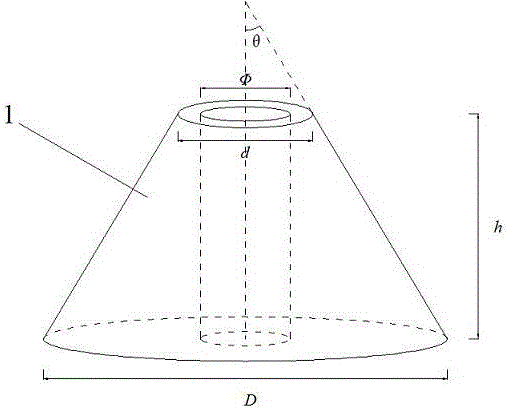

[0030] Step 2: According to the diameter of the pile foundation 4 (generally 0.6 or 0.8 or 1.0 or 1.2 or 1.5m) and the height of the karst 2 (generally 3 or 5 or 7 or 9 or 10m), determine the size of the pocket 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com