Air ejector with own power rotation arranged at bottom of biological fermentation tank

A technology of air injector and biofermentation tank, which is applied in the direction of bioreactor/fermentation tank combination, special-purpose bioreactor/fermentation tank, biochemical equipment, etc., can solve the problems such as difficult to meet the requirements of microbial fermentation process, and achieve improvement Oxygen utilization, power reduction, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

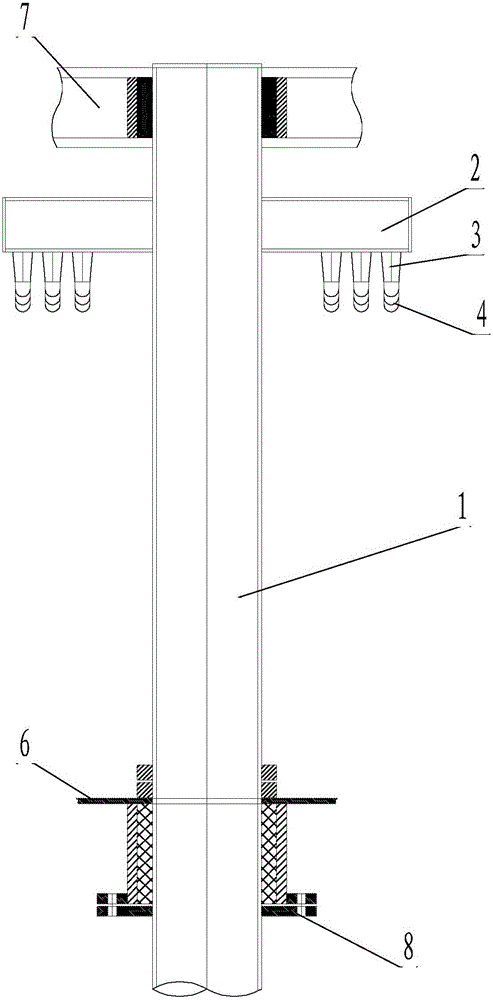

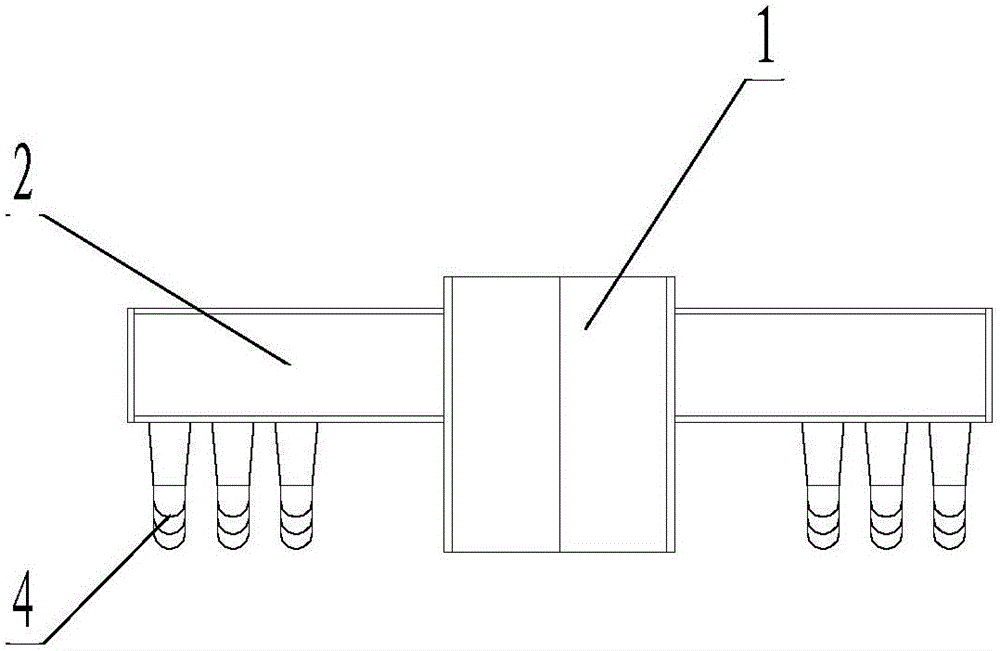

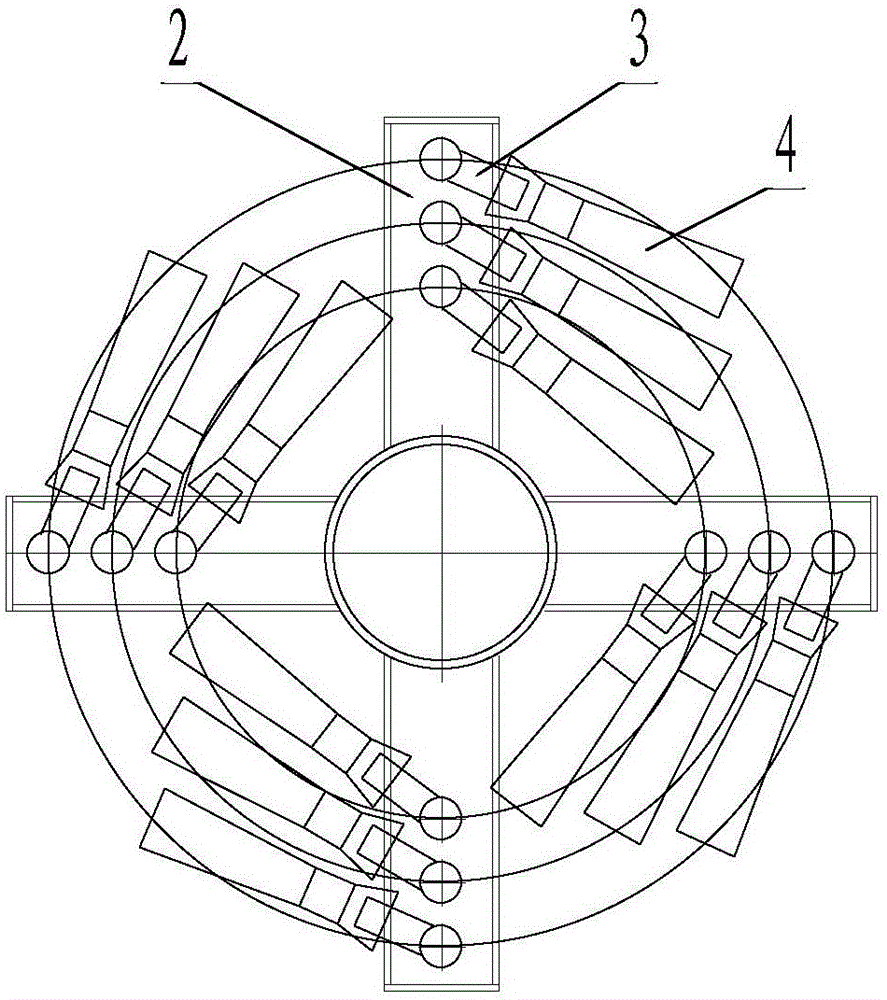

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a self-rotating air injector is installed at the bottom of the biological fermentation tank. An air inlet pipe 1 is installed at the bottom 6 center of the biological fermentation tank to be connected with the air delivery pipe outside the fermentation tank. There are four air outlet branch pipes 2 equidistantly arranged on the top, and each air outlet branch pipe is located on the same horizontal plane, and the air outlet branch pipes are radially evenly distributed with three branch pipes 3, and a nozzle with an adjustable direction and angle is installed on each branch pipe 4. The direction of the nozzle 4 is adjusted to the concentric circle formed when the injector rotates, facing the opposite direction of the injector's rotation direction. The upper end of the air intake pipe is provided with an upper shaft sleeve 7, and the lower end of the air intake pipe and the bottom of the tank 6 have a lower ...

Embodiment 2

[0029] Such as Figure 6 , Figure 7 As shown, the upper end of the air intake pipe 1 is equipped with a coupling 9, the coupling is connected with the stirring shaft 5, and the lower end of the air intake pipe 1 and the bottom of the tank 6 have a lower bushing 8. The air launcher rotates coaxially with the stirring shaft. For large-capacity biological fermentation tanks.

[0030] The parts not described in embodiment 2 are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com