Plasma nanometer bubble generator

A technology of nano-bubbles and generators, applied in water aeration, sustainable biological treatment, chemical instruments and methods, etc., to achieve the effects of small bubble diameter, high internal energy, and high oxygen utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

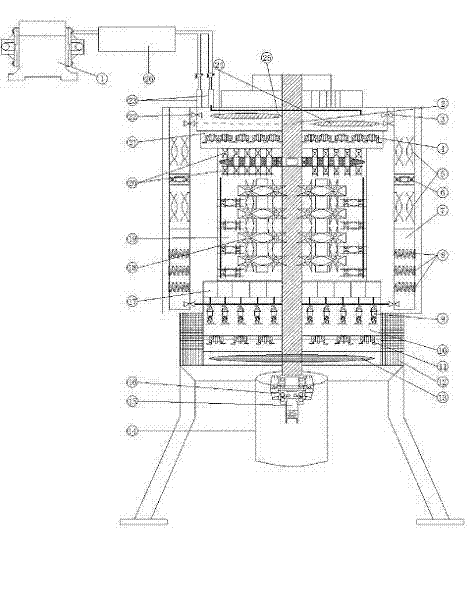

[0018] The air is pressurized by the air pump 1 and enters the gas ionization device 26, and the ionized gas enters the balance chamber 25 through the air inlet 23, and the water entering through the water inlet 3 and the water inlet 22 in the balance chamber is separated by the drive shaft. 2. The effects of the driven balance plate 24 and the balance assembly 4 reach an overbalanced state. In the super-balanced state, the gas-water flow enters the balance guide chamber 21 under the pressure of the air pump 1, and enters the disturbance chamber 19 through the balance guide assembly 20. In the disturbance chamber, the disturbance assembly 18 performs 4-stage balance disturbance to generate fine bubbles and then enters the bubble liquid. Disperse waterway 17.

[0019] When excessive pressure is generated in the balance chamber, the gas is introduced into the bypass pressure divider chamber 7 on both sides, and enters the balance component 9 after the pressure is buffered by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com