Water circulation system for vacuum setting machine

A technology of setting machine and water circulation, applied in the field of water circulation system and water circulation system of vacuum setting machine, can solve the problems that pipes cannot be cooled in a comprehensive and timely manner, cannot quickly form a circulating water circuit, and the time of a single water circulation is long, etc. Cost control, prevention of high water temperature, and short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

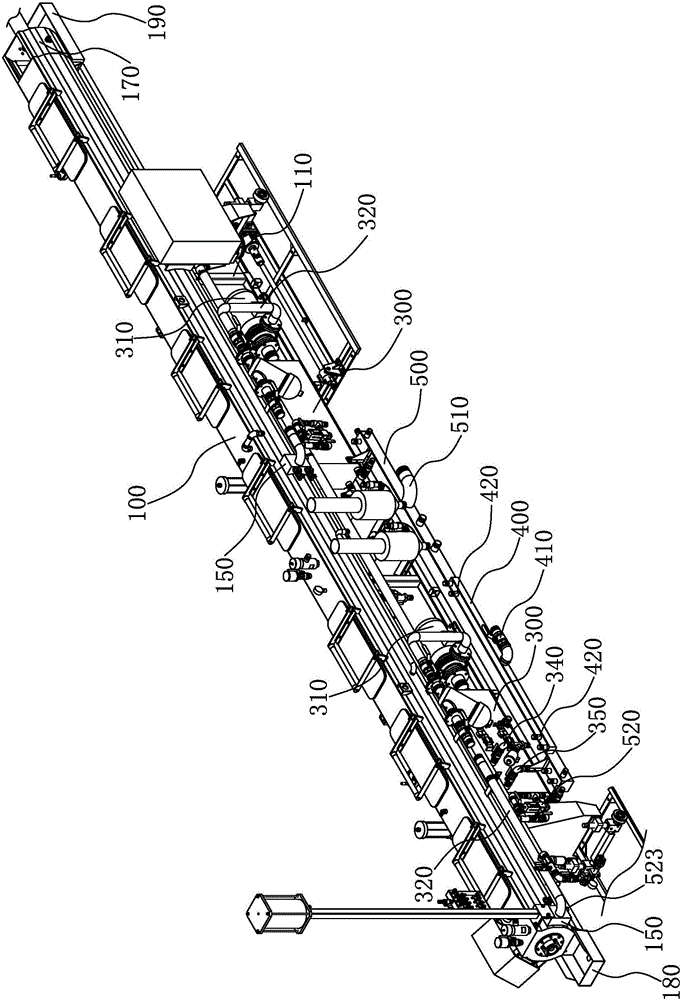

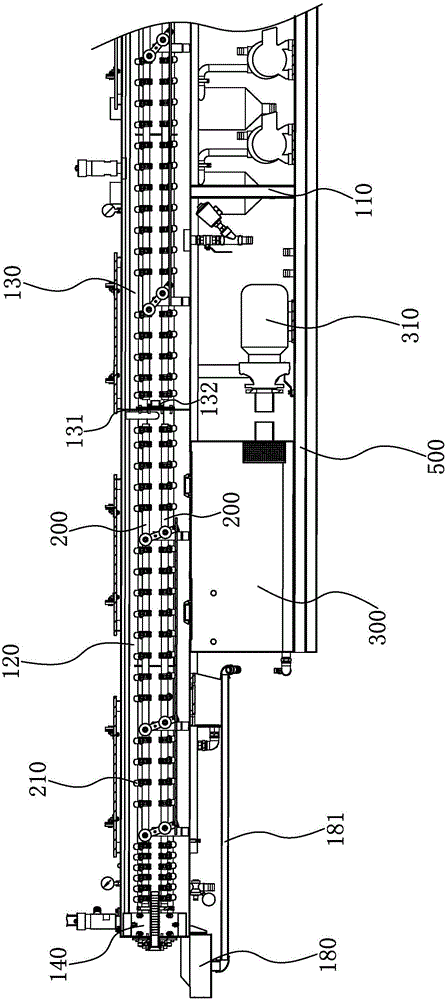

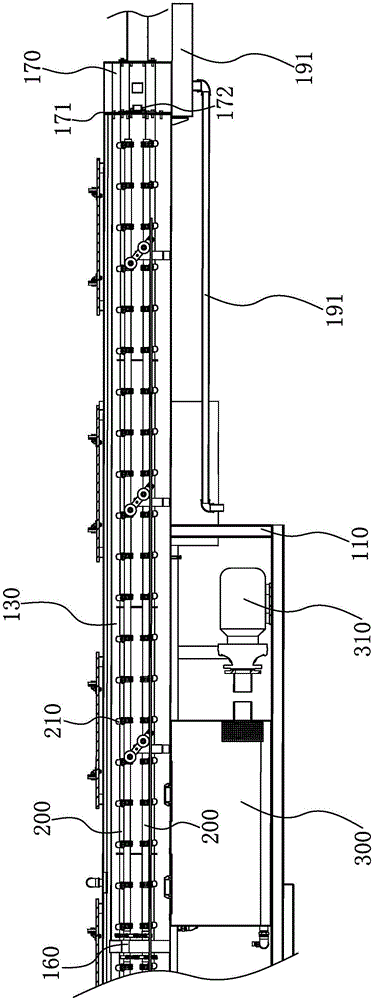

[0056] Such as Figure 1 to Figure 3 As shown, the present invention is used in the water circulation system of the vacuum setting machine, which is a part of the vacuum setting machine. The water circulation system includes a box body 100, a spray assembly, a water supply assembly, a water inlet assembly and a drainage assembly.

[0057] The box body 100 extends in the axial direction, and the inside of the box body 100 is axially penetrated to form an accommodating cavity for pipes to pass through. The box body 100 has a feed end and a discharge end.

[0058] Such as Figure 2 to Figure 4As shown, the shower assembly includes a shower pipe 200 and a shower head 210 .

[0059] There are two groups of spray pipes 200 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com