Log cutting device

A technology for cutting devices and logs, applied to feeding devices, circular saws, sawing components, etc., can solve problems such as complicated cutting operations, and achieve the effect of ensuring normal transmission and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

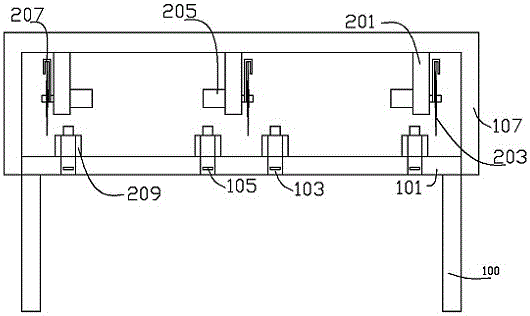

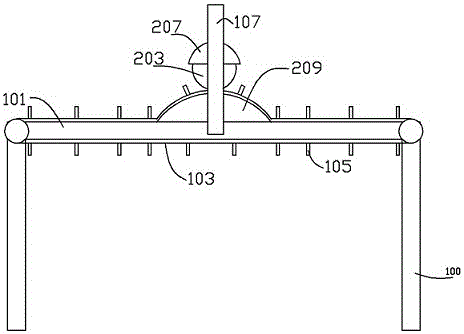

[0015] The reference signs in the accompanying drawings of the description include: frame 100, workbench 101, transmission chain 103, gear rod 105, support rod 107, connecting rod 201, saw blade 203, motor 205, circular baffle 207, arc block 209.

[0016] Such as figure 1 and figure 2 The log cutting device shown includes a frame 100, a workbench 101 and three groups of cutting mechanisms. The workbench 101 is connected above the frame 100. There are two groups of conveying chains 103 for conveying logs. The conveying chains 103 are provided with gear rods 105. The workbench 101 is provided with support rods 107 connected to the cutting mechanism. The two ends of the support rods 107 are connected to both sides of the workbench 101. Cutting mechanism comprises connecting rod 201 and saw blade 203, and the lower end surface of support rod 107 is connected connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com