Polishing platform

A platform and working platform technology, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of large investment, high energy consumption, and poor effect, so as to reduce investment and avoid Hazards, the effect of avoiding dust floating into the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

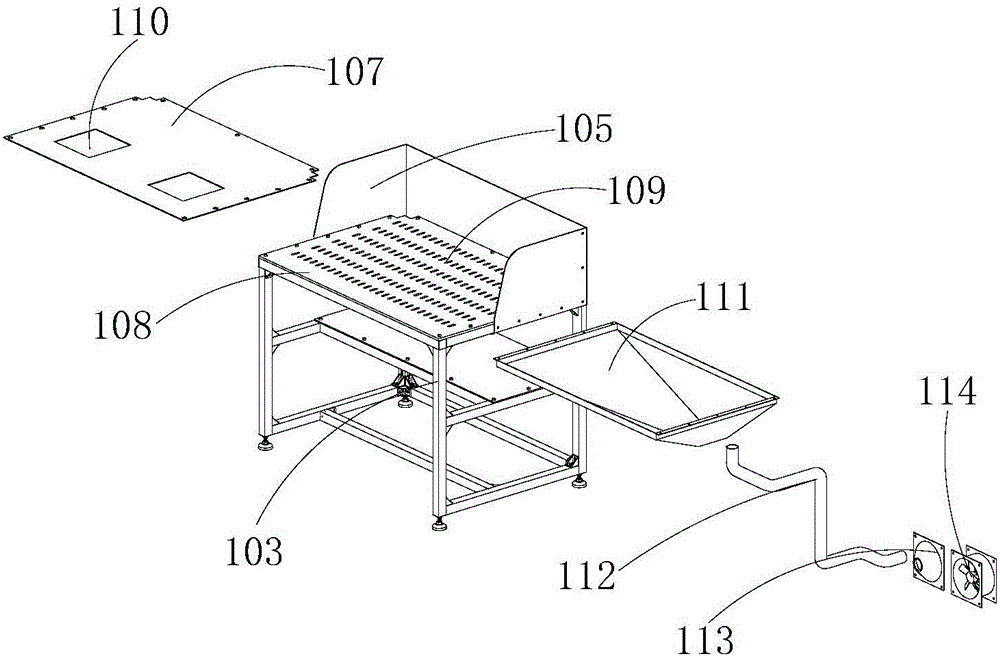

[0045] refer to figure 1 and figure 2 , the present embodiment provides a grinding platform, including a base 103, a working platform and a suction device 104, the working platform and the suction device 104 are respectively installed on the base 103, and the working platform is provided with a plurality of first through holes 109, The plurality of first through holes 109 communicate with the input ends of the suction device 104 respectively.

[0046] The grinding platform provided in this embodiment has its own suction device 104, which can suck away the dust that occurs during the grinding process of the workpiece, avoiding the dust from floating into the air, thereby avoiding harm to the health of the staff in the factory building. At the same time, since this kind of grinding platform has its own suction device 104, it is not necessary to set up additional large-scale dust collection equipment, thereby reducing investment, and the energy consumption of this small suction...

Embodiment 2

[0057] refer to image 3 and Figure 4 , this embodiment also provides a grinding platform, this embodiment is a further improvement on the basis of the technical solution of embodiment 1, the technical solution described in embodiment 1 is also applicable to this embodiment, the disclosed The technical solution will not be described repeatedly.

[0058] Specifically, the difference between this embodiment and Embodiment 1 is that the polishing platform provided by this embodiment also includes a third desktop 115, the third desktop 115 is detachably connected to the first desktop 108, and the third desktop 115 is located in the second through hole 110 , and the thickness of the third desktop 115 is the same as that of the second desktop 107 .

[0059] The 3rd desktop 115 can change the size of the second through hole 110, because the power of the suction device 104 is constant, therefore, if the size of the second through hole 110 is smaller, the suction force at the second...

Embodiment 3

[0063] refer to Figure 5 , this embodiment also provides a grinding platform, this embodiment is a further improvement on the basis of the technical solution of embodiment 1, the technical solution described in embodiment 1 is also applicable to this embodiment, the disclosed The technical solution will not be described repeatedly.

[0064] Specifically, the difference between this embodiment and Embodiment 1 is that the grinding platform provided by this embodiment also includes a bracket 120 and a lighting lamp 117, the bracket 120 is installed on the base 103, the lighting lamp 117 is installed on the bracket 120, and the lighting lamp 117 Located above the second desktop 107. The setting of the illuminating lamp 117 can make the processing personnel observe the workpiece more comprehensively, thereby making the workpiece be polished more meticulously.

[0065] The bracket 120 includes a second plurality of aluminum profiles and a plurality of second corner joints 119, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com