Method to make standard surface roughness by boring aluminum alloy

A surface roughness, aluminum alloy technology, used in turning equipment, manufacturing tools, toolholder accessories, etc., can solve problems such as unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

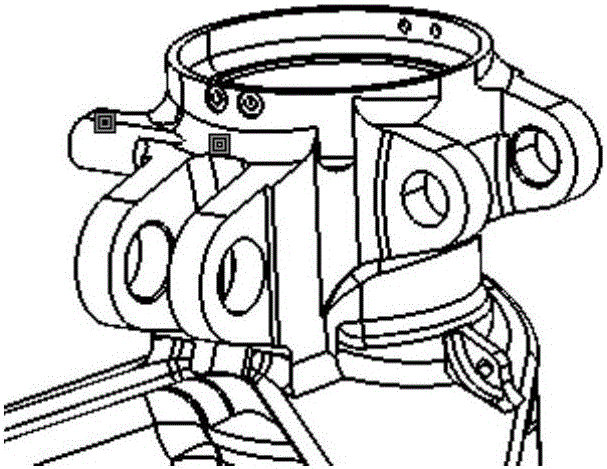

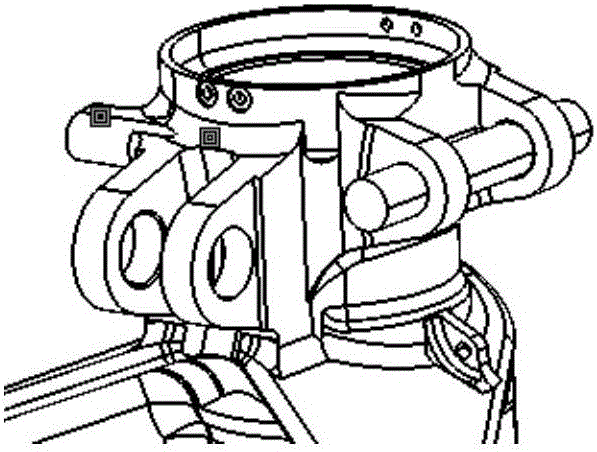

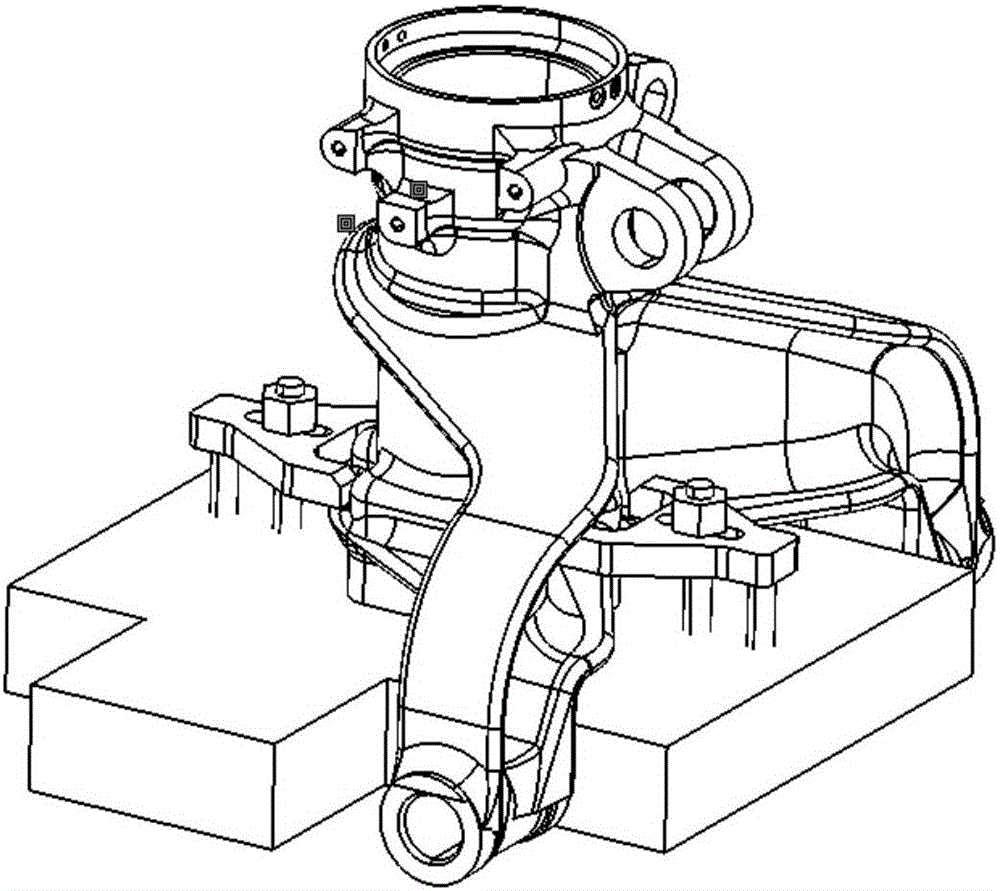

Image

Examples

Embodiment

[0045] Use concrete processing method of the present invention as follows:

[0046] 1. Wipe the parts clean and check whether the positioning reference of the part is flat; check that there is no gap between the tooling and the positioning reference of the part; prepare rough and fine boring tools for processing, and check the integrity of the blade.

[0047] 2. Lay the part flat to prevent deformation of the part, that is, install a dial indicator on the symmetrical position on both sides of the top of the hole to detect the slight deformation of the part caused by the clamping force.

[0048] 3. When clamping parts, adopt 4 pressure plates to press symmetrically. Since the parts are high, both the top and the bottom need to be focused during processing, otherwise the parts are easy to vibrate. Using the characteristics of the parts, the original two holes of the parts are connected to a standard rod , as the pressed point for compaction.

[0049] 4. Determine the origin of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com