A kind of preparation method of brewing powder and brewing powder thereof

A production method and technology for preparing powder, applied in the field of food processing, can solve the problems of poor taste, affecting the taste of food, and little specific effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

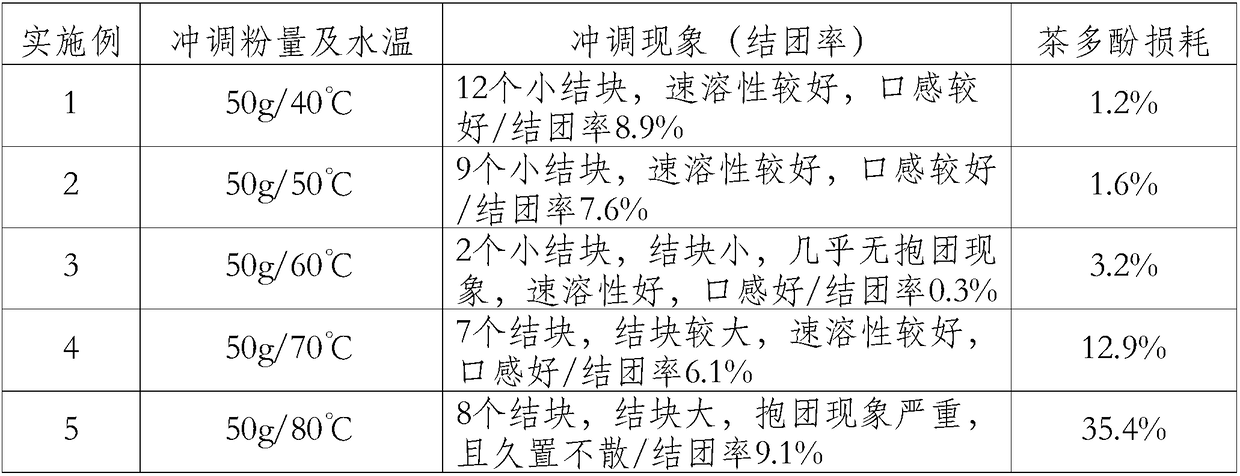

Examples

Embodiment 1

[0021] The weight ratio of raw materials is 50g of corn starch, 15g of whey protein, 13g of sunflower oil, 10g of high amylose corn starch, 4.45g of fructooligosaccharide, 3.68g of xylitol, 2g of soybean powdery phospholipid, 0.5g of konjac gum, and conjugated sub- Oleic acid 0.2g, casein calcium peptide 0.16g, tea polyphenol 0.6g, tea polysaccharide 0.5g, multivitamin 0.1g, molecular distillation monoglyceride 0.05g, sucrose ester 0.05g, potassium chloride 1.2g, calcium carbonate 1.2g, magnesium sulfate 1g, konjac gum 0.5g, sodium chloride 0.16g, casein calcium peptide 0.2g, sodium erythorbate 0.2g, taurine 0.03g, ascorbyl palmitate 0.03g, ferrous sulfate 0.03g, Zinc sulfate 0.01g, manganese sulfate 0.005g, chromium picolinate 0.003g, trisodium phosphate 0.003g.

[0022] Disperse 50g of cornstarch and 10g of high amylose cornstarch in 240mL of water to make a cold starch solution.

[0023] Dissolve 0.05 g of sucrose ester and 0.05 g of molecularly distilled monoglyceride com...

Embodiment 2

[0028] The weight ratio of raw materials is 45g of pea starch, 10g of whey protein, 10g of sunflower oil, 5g of high amylose corn starch, 4g of fructooligosaccharide, 3g of xylitol, 2g of soybean powdery phospholipid, 0.5g of konjac gum, conjugated linoleic acid 0.2g, casein calcium peptide 0.1g, tea polyphenol 0.4g, tea polysaccharide 0.4g, multivitamin 0.1g, molecular distillation monoglyceride 0.05g, sucrose ester 0.05g, potassium chloride 1.0g, calcium carbonate 1.5g , magnesium sulfate 1g, konjac gum 0.5g, sodium chloride 0.16g, casein calcium peptide 0.2g, sodium erythorbate 0.2g, taurine 0.03g, ascorbyl palmitate 0.03g, ferrous sulfate 0.03g, zinc sulfate 0.01g, manganese sulfate 0.002g, chromium picolinate 0.005g, trisodium phosphate 0.005g.

[0029] Disperse 50g pea starch and 10g high amylose corn starch in 240mL water to make cold starch solution.

[0030] Dissolve 0.05 g of sucrose ester and 0.05 g of molecularly distilled monoglyceride compound emulsifier in 10 g...

Embodiment 3

[0035] The weight ratio of raw materials is mung bean starch 50g, whey protein 20g, sunflower oil 13g, high amylose corn starch 10g, fructooligosaccharide 5g, xylitol 4g, soybean powder phospholipid 3g, konjac gum 0.5g, conjugated linoleic acid 0.3g, casein calcium peptide 0.16g, tea polyphenol 0.6g, tea polysaccharide 0.6g, multivitamin 0.1g, molecular distillation monoglyceride 0.05g, sucrose ester 0.05g, potassium chloride 1.5g, calcium carbonate 1.2g , magnesium sulfate 1g, konjac gum 0.7g, sodium chloride 0.2g, casein calcium peptide 0.5g, sodium erythorbate 0.2g, taurine 0.03g, ascorbyl palmitate 0.03g, ferrous sulfate 0.03g, zinc sulfate 0.01g, manganese sulfate 0.007g, chromium picolinate 0.003g, trisodium phosphate 0.007g.

[0036] Disperse 50g mung bean starch and 10g high amylose corn starch in 240mL water to make cold starch solution.

[0037] Dissolve 0.05 g of sucrose ester and 0.05 g of molecularly distilled monoglyceride compound emulsifier in 13 g of sunflowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com