Preparation method of soluble polymers prepared by compound enzyme modified whey protein

A whey protein and soluble technology, applied in the field of protein preparation, can solve the problems of insignificant viscosity change, poor gelling ability, slow growth rate, etc., and achieve the effect of transparent appearance, fast growth rate and fast viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: In this embodiment, a method for preparing soluble polymers by modifying whey protein with compound enzyme is completed by the following steps:

[0028] Step 1. Stir and preheat 100 mL of whey protein solution with a mass fraction of 10% at 50° C. for 5 minutes, and adjust the pH value to 8.0 with NaOH solution with a concentration of 1.0 mol / L;

[0029] Step 2, then add 10 μL of chymotrypsin (chymotrypsin) to carry out the hydrolysis reaction at 50°C for 30s, add 0.1mol / L NaOH dropwise during the hydrolysis process to maintain the pH value, and immediately heat at 85°C for 5 minutes after the reaction Inactivation;

[0030] Step 3, cooling to 50°C with water, adding 5.0 U / g of transglutaminase mTGase, and reacting for 1 hour;

[0031] Step 4: heat up to 85°C, react for 5 minutes to inactivate the enzyme, and cool to room temperature to obtain a soluble polymer.

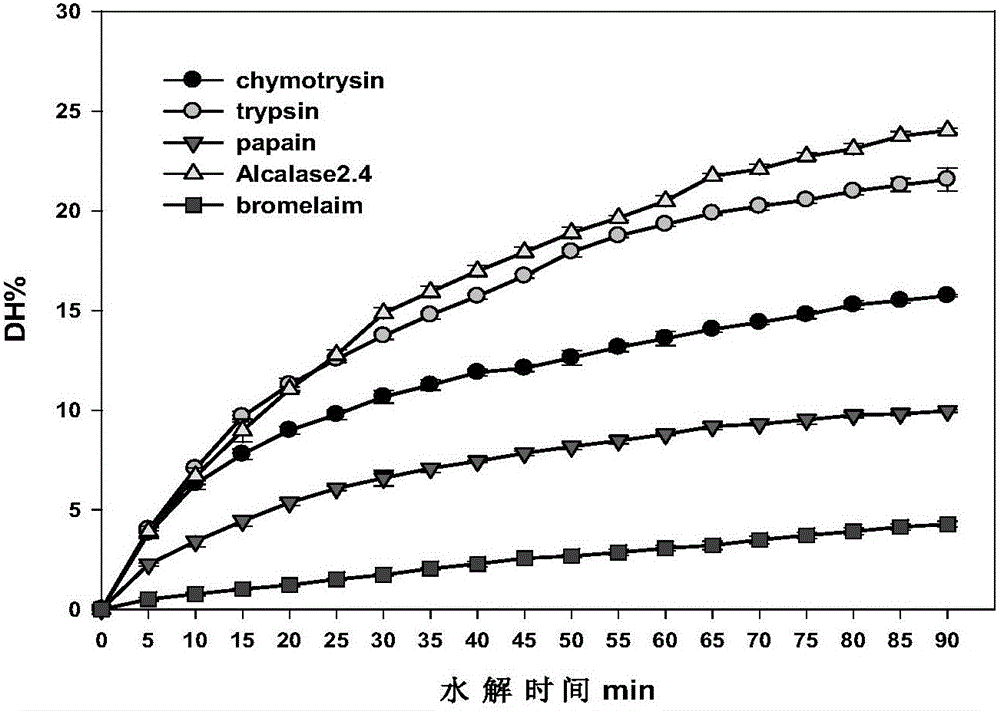

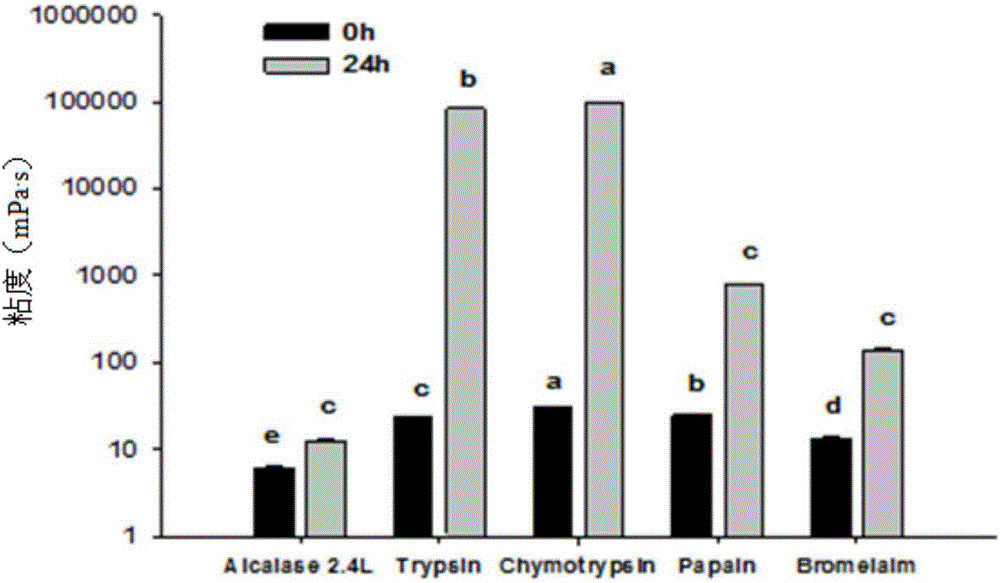

[0032] The Chymotrypsin of this embodiment has an extremely low degree of hydrolysis, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com