Bait and making method thereof

A production method and bait technology, which are applied in fishing, fishing accessories, applications, etc., can solve the problems of tilapia's feeding desire reduction, difficulty, and lack of attractiveness, so as to achieve strong operability and attractiveness, and increase lure The effect of food habits and fast fishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

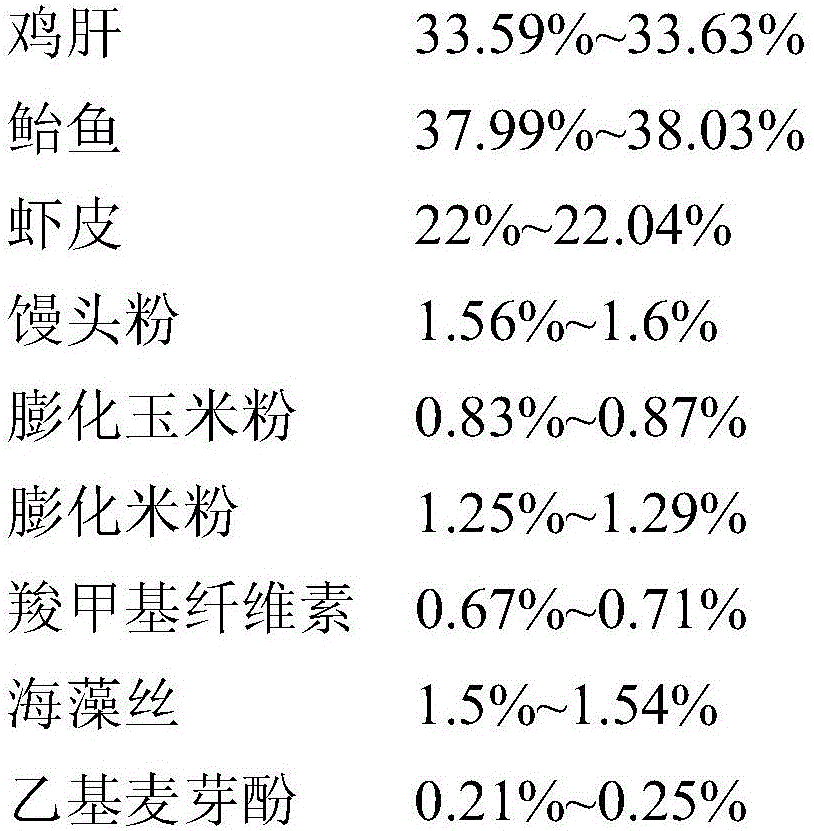

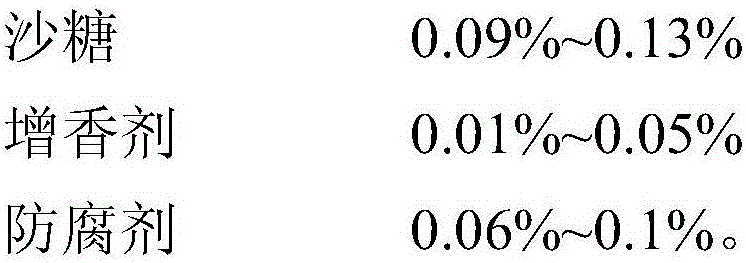

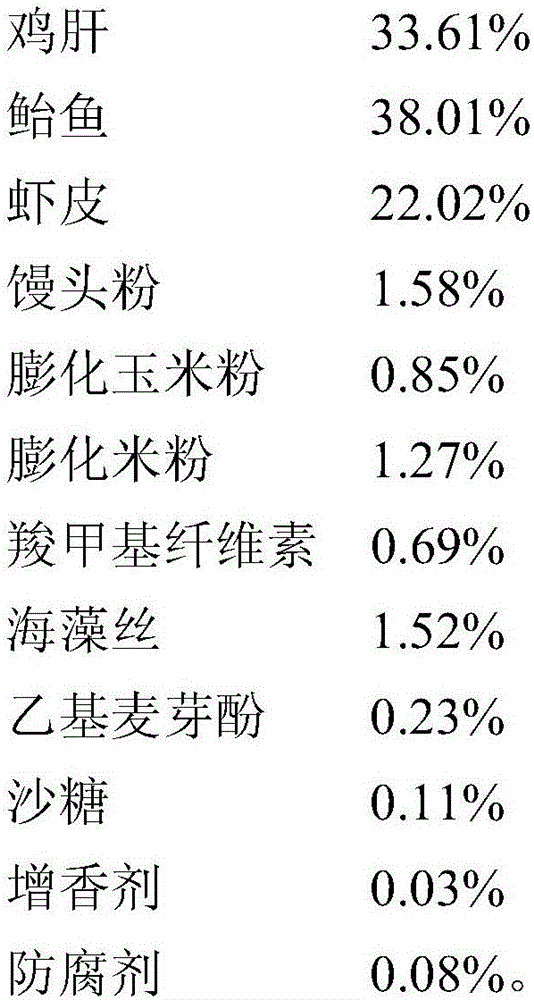

[0029] The weight percentage of each component is: chicken liver 33.61%, mackerel 38.01%, dried shrimp skin 22.02%, steamed bread flour 1.58%, puffed corn flour 0.85%, puffed rice flour 1.27%, carboxymethyl cellulose (CMC) 0.69%, seaweed silk 1.52% %, ethyl maltol 0.23%, granulated sugar 0.11%, flavor enhancer 0.03%, preservative 0.08%.

[0030] Specifically: 53 catties of chicken liver, 60 catties of mackerel, 35 catties of shrimp skin, 1250 grams of steamed bread powder, 500 grams of puffed corn flour, 1000 grams of puffed rice flour, 545 grams of carboxymethyl cellulose, 1200 grams of seaweed silk, 180 grams of ethyl maltol grams, 90 grams of granulated sugar, 27 grams of milk powder, and 65 grams of potassium sorbate.

[0031] When making, include the following steps:

[0032] 1.53 catties of chicken liver treatment: degreasing, removing gluten, washing, cooking, mixing ethyl maltol and granulated sugar, adding 1000 grams of water to dissolve, adding to the chicken liver, ...

Embodiment 2

[0042] The weight percentage of each component is: chicken liver 33.59%, mackerel 38.01%, dried shrimp skin 22.02%, steamed bread flour 1.58%, puffed corn flour 0.85%, puffed rice flour 1.27%, carboxymethyl cellulose (CMC) 0.69%, seaweed silk 1.52% %, ethyl maltol 0.23%, granulated sugar 0.11%, flavor enhancer 0.03%, preservative 0.1%.

[0043] Specifically: 53 catties of chicken liver, 60 catties of mackerel, 35 catties of shrimp skin, 1250 grams of steamed bread powder, 500 grams of puffed corn flour, 1000 grams of puffed rice flour, 545 grams of carboxymethyl cellulose, 1200 grams of seaweed silk, 180 grams of ethyl maltol grams, 90 grams of granulated sugar, 27 grams of milk powder, and 79 grams of potassium sorbate.

[0044] When making, include the following steps:

[0045] 1.53 catties of chicken liver treatment: degreasing, removing gluten, washing, cooking, mixing ethyl maltol and granulated sugar, adding 1000 grams of water to dissolve, adding to the chicken liver, a...

Embodiment 3

[0055] The weight percentage of each component is: chicken liver 33.59%, mackerel 38.01%, shrimp skin 22%, steamed bread powder 1.58%, puffed corn flour 0.85%, puffed rice flour 1.27%, carboxymethyl cellulose (CMC) 0.69%, seaweed silk 1.52% %, ethyl maltol 0.23%, granulated sugar 0.11%, flavor enhancer 0.05%, preservative 0.1%.

[0056] The specific weight is: 53 catties of chicken liver, 60 catties of mackerel, 35 catties of shrimp skin, 1250 grams of steamed bread flour, 500 grams of puffed corn flour, 1000 grams of puffed rice flour, 545 grams of carboxymethyl cellulose, 1200 grams of seaweed shreds, ethyl maltol 180 grams, 90 grams of granulated sugar, 39 grams of milk powder, 79 grams of potassium sorbate.

[0057] When making, include the following steps:

[0058] 1.53 catties of chicken liver treatment: degreasing, removing gluten, washing, cooking, mixing ethyl maltol and granulated sugar, adding 1000 grams of water to dissolve, adding to the chicken liver, and mincing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com