A large-scale photovoltaic power station battery panel dry cleaning system and its control method

A photovoltaic power station and dry cleaning technology, applied in the field of solar photovoltaic power generation, can solve the problems of reduced operation and maintenance economy, reduced photoelectric conversion efficiency, secondary pollution, etc., and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below using the drawings and specific embodiments.

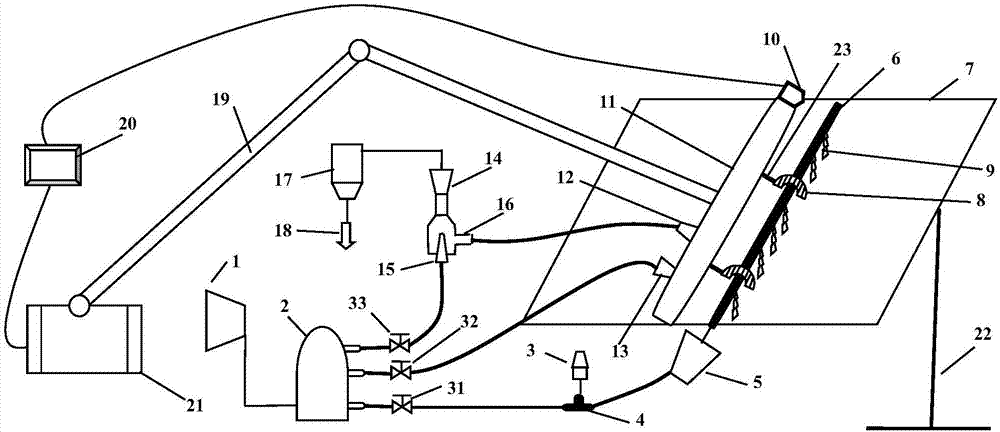

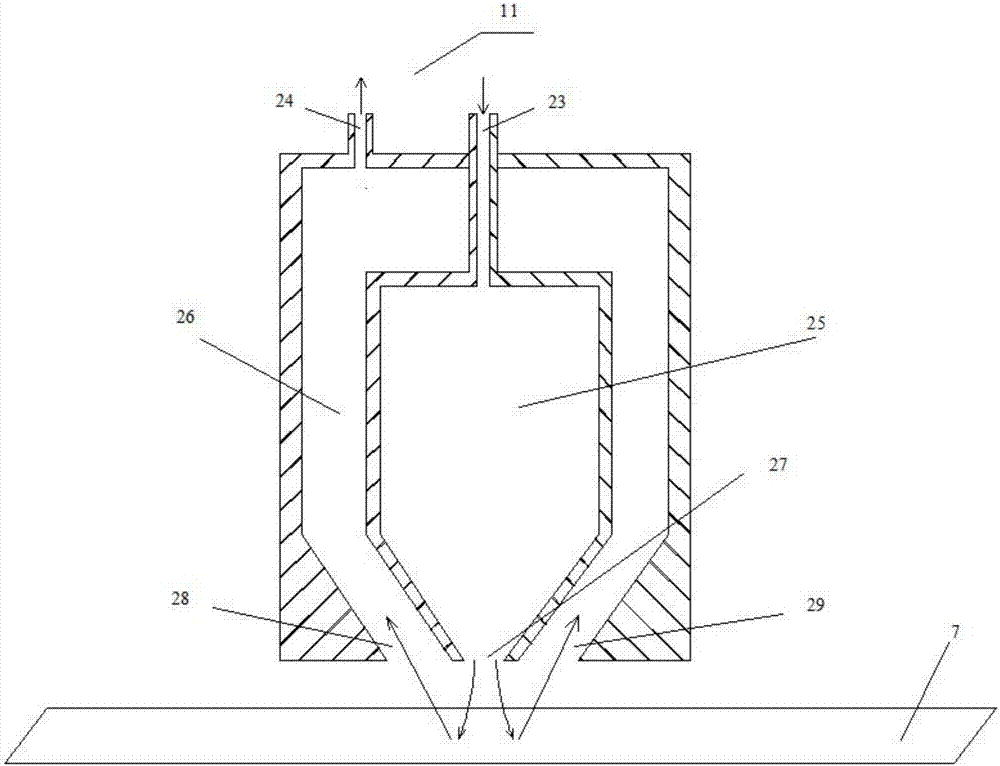

[0021] refer to figure 1 , a large-scale photovoltaic power station battery panel dry cleaning system according to the present invention, comprising that the compressed air outlet of the air compressor 1 is connected to the air inlet of the high-pressure gas storage tank 2, and the first air outlet of the high-pressure gas storage tank 2 passes through the first The throttle valve 31 communicates with the three-way pipe connection 4, and the three-way pipe connection 4 communicates with the air inlet of the air motor 5 and the high-pressure gas safety valve 3 respectively. In the bearing bush 8 where the cleaning nozzle 11 is fixed, a friction-resistant cloth 9 is embedded under the rotating shaft 6; the second air outlet of the high-pressure gas storage tank 2 communicates with the high-pressure purge air interface 13 of the dry combined cleaning nozzle 11 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com