Fully mechanized caving face inter-frame oriented hydraulic fracturing top-coal weakening method

A technology for hydraulic fracturing and top coal, which is used in surface mining, earth-moving drilling, and fluid extraction. It can solve the problems of long water injection time, large water injection volume, gas explosion, etc., and achieve high recovery rate mining and high solution cost. , to improve the effect of spoofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

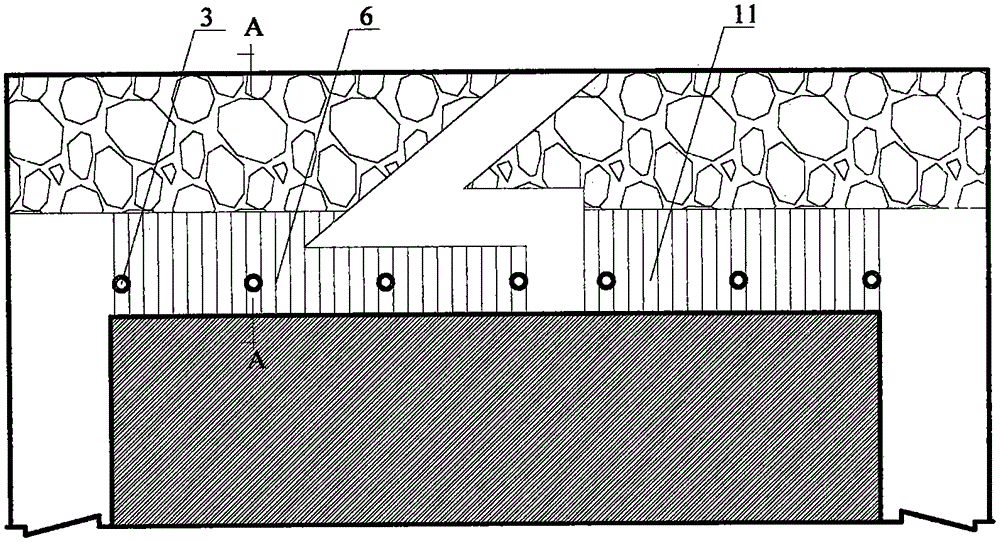

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0024] The average thickness of the coal seam in a mine is 13.7m, which is a medium-hard coal seam, and the coal seam dip angle is 1-3°. The fully mechanized top coal caving technology is used for mining. The coal cutting height is 3.2m, and the average coal caving height is 10.5m. Before directional hydraulic fracturing, The top-coal recovery rate of the working face is 40% to 50%. According to the detection and analysis of intelligent TV imaging technology, the integrity of the top-coal above 4.5m above the support of the working face is better. According to the actual situation on site, in order to weaken the complete top-coal area above 4.5m of the support, first use a pneumatic or hydraulic rock bolt drill to drill vertically between the fully-mechanized caving hydraulic supports (6) in the fully-mechanized caving face (11) hole (3), the drilling di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com