Spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing

A technology of helical type and impactor, which is applied to the drilling driving device, drilling equipment, impact drilling and other directions in the wellbore, can solve the problems of low rock breaking efficiency and unsatisfactory use effect of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

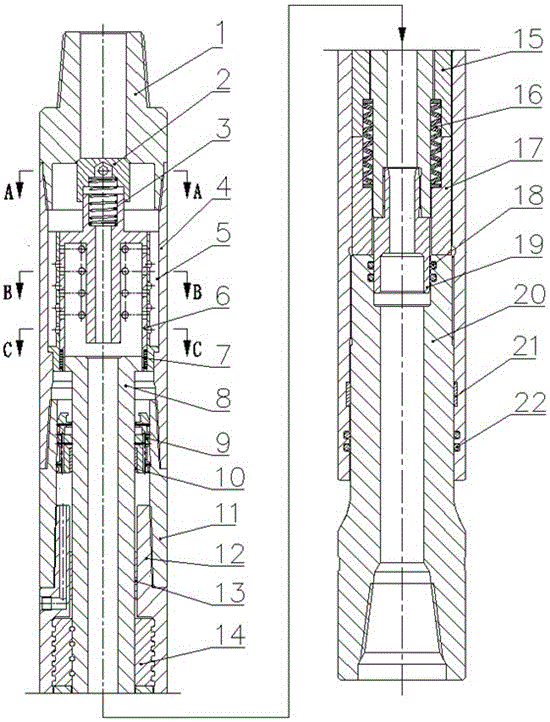

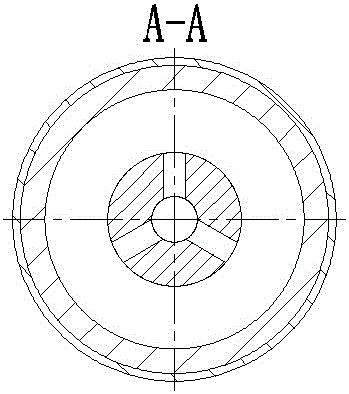

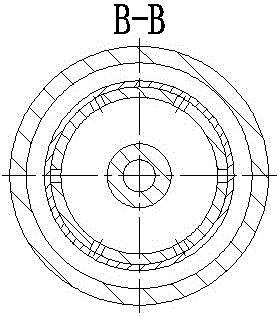

[0017] See attached figure 1 , a spiral double-stage composite impactor for increasing drilling speed and increasing efficiency. 8. Movable floating plug 9, floating plug sealing ring 10, middle joint 11, lower casing 12, lower casing sealing ring 13, locking sleeve 14, upper sleeve 15, disc spring 16, lower sleeve 17, nozzle seal Ring 18, impact nozzle 19, lower joint 20, support sleeve 21 and lower joint sealing ring 22, characterized in that: upper joint 1, upper shell 4, middle joint 11, lower shell 12 and lower joint 20 pass through the thread in sequence After being fixed, a cavity is formed inside, and the cavity is followed by valve body 2, valve body spring 3, driving hammer 6, central tube 8, disc spring 16, impact bumper 20 from top to bottom; the upper end of valve body 2 is provided with a circumferential uniform The lower end of the three flowing water throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com