A prefabricated box culvert and rapid positioning construction method

A construction method and technology of box culverts, which are applied in the directions of buildings and road bottom layers, can solve the problems that the durability and seismic performance cannot well meet the construction requirements, unfavorable transportation, time-consuming and laborious maintenance, etc., saving manpower and material resources, The effect of fast construction and less excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

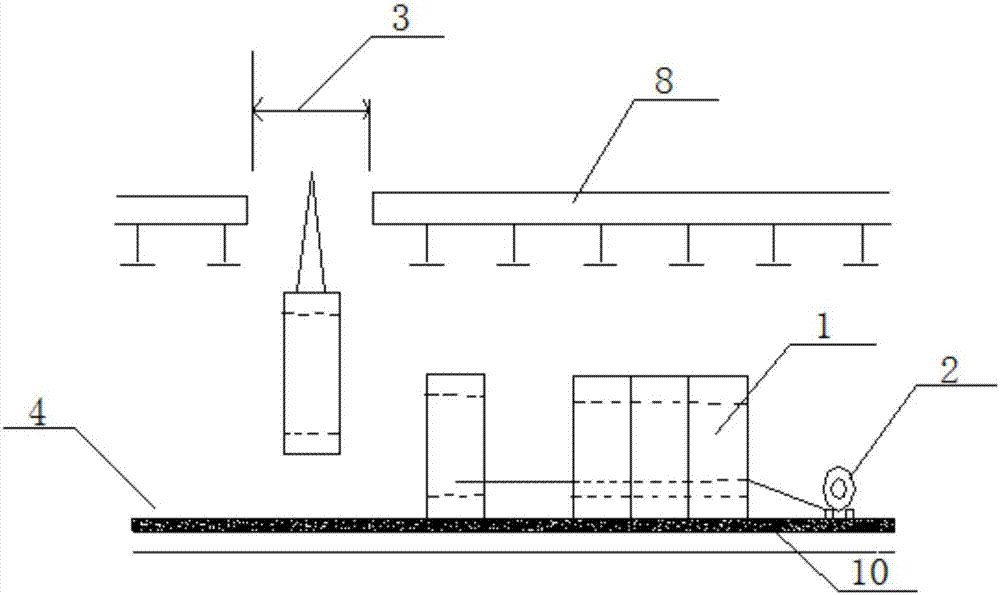

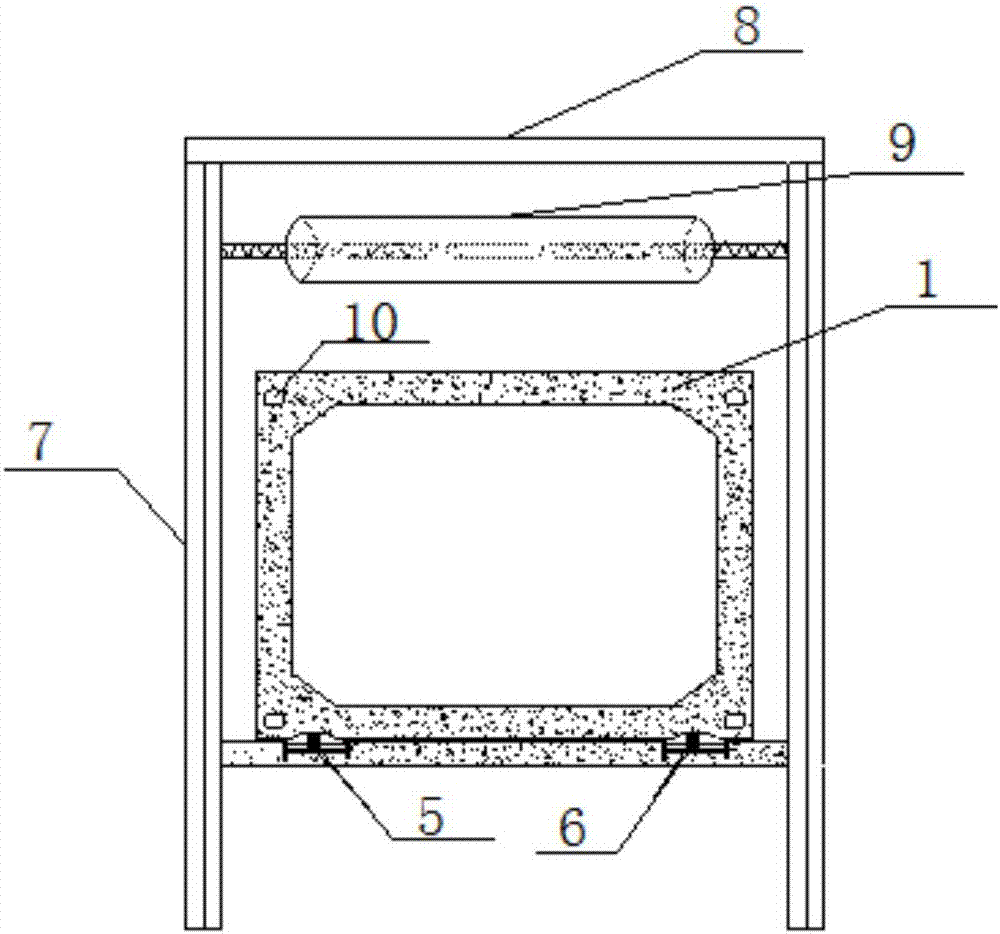

[0033] Such as Figure 1~3 The schematic diagram of the operation process of the prefabricated box culvert quick positioning construction method shown in the present invention includes a box culvert 1, a tractor 2, an inlet 3, a groove 4, H-shaped steel 5, a steel wheel 6, a steel plate 7, a cover plate 8, a spiral Multiple components such as anchor rod 9, base plate 10 and reserved hole 11.

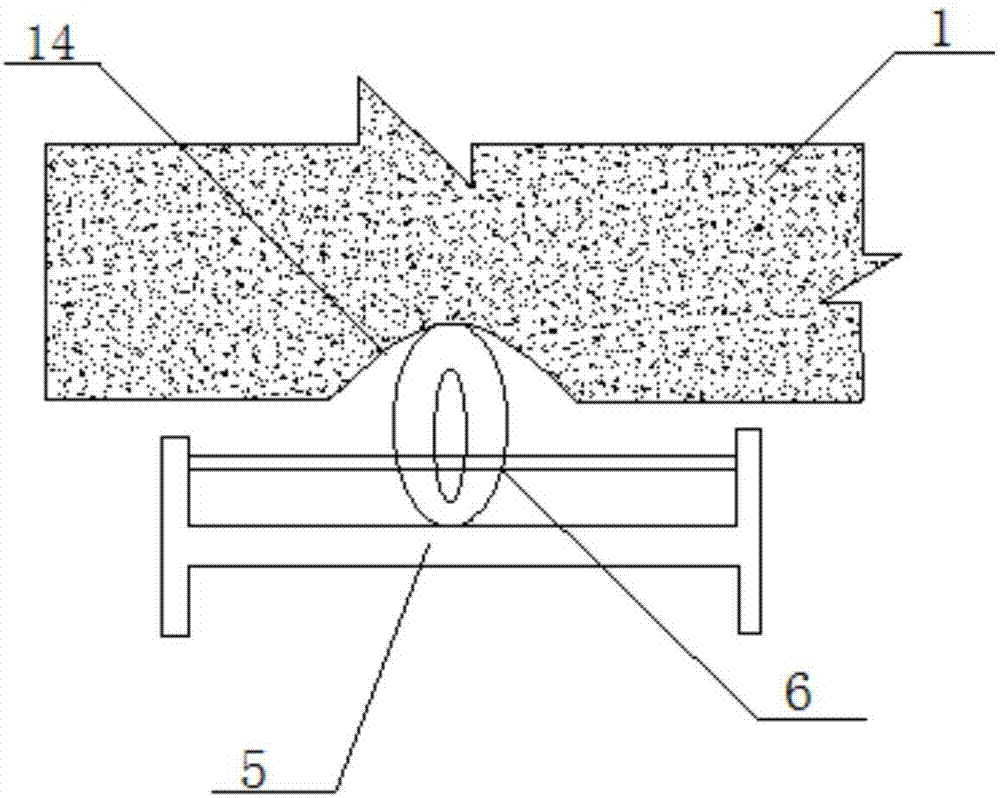

[0034] The box culvert 1 is a hollow tubular structure with a quadrilateral cross-section, and the two opposite sides of the box culvert 1 are the A surface and the B surface respectively, such as Figure 4 and Figure 5 As shown, a plurality of grooves 12 are arranged on the side of the A surface, and a plurality of protrusions 13 are arranged on the side of the B surface, the positions of the grooves 12 correspond to the positions of the protrusions 13, and the adjacent grooves When the protrusion 12 is connected with the protrusion 13, the protrusion 13 is stuck in the groove 12, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com