Automatic long bamboo fiber cleaning device

An automatic cleaning and fiber technology, applied in the processing of plant fibers, liquid/gas/vapor fibers/cotton sliver/rovings of other plant raw materials, etc. High labor intensity and other problems, to achieve the effect of efficient and clean cleaning, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

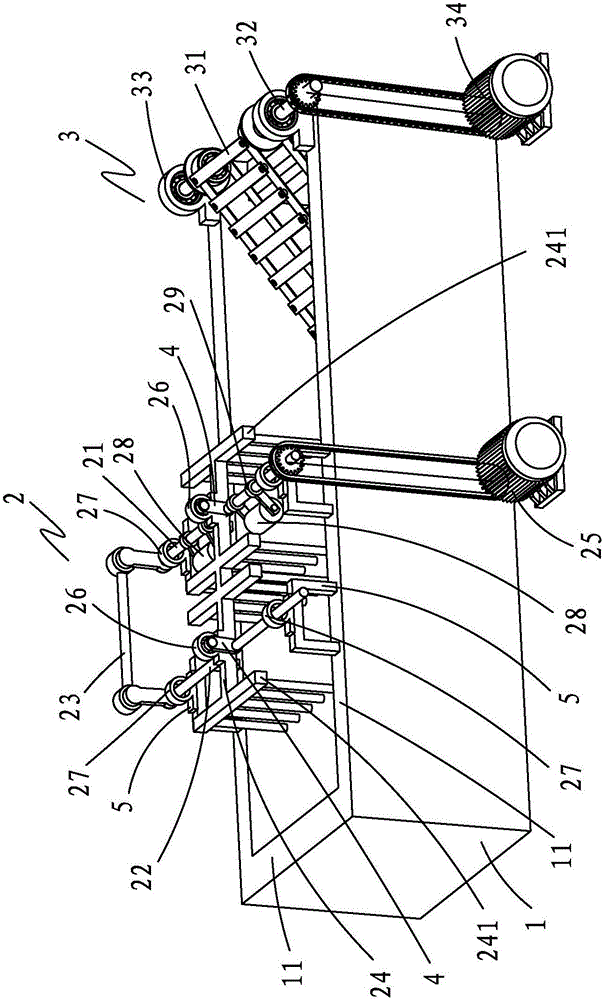

[0013] see figure 1 As shown, the embodiments of the present invention will be described in detail.

[0014] Such as figure 1 Shown, a kind of long bamboo fiber automatic cleaning device that the present invention relates to, described automatic cleaning device comprises cleaning pool 1, parallel double crank mechanism 2 and delivery system 3, described parallel double crank mechanism 2 and delivery system 3 respectively The front and back are erected on the cleaning pool 1, and the parallel double crank mechanism 2 includes a driving crankshaft 21, a driven crankshaft 22, a connecting rod 23, a palladium gear frame 24 and a first motor 25, the driving crankshaft 21 and the driven crankshaft 21 One end of the driving crankshaft 22 is connected through a connecting rod 23, the other end of the driving crankshaft 21 is connected with the first motor 25, and the driving crankshaft 21 and the driven crankshaft 22 are respectively connected to the palladium tooth assembly frame 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com