Device for producing synthesis gas through biomass gasification and method of device

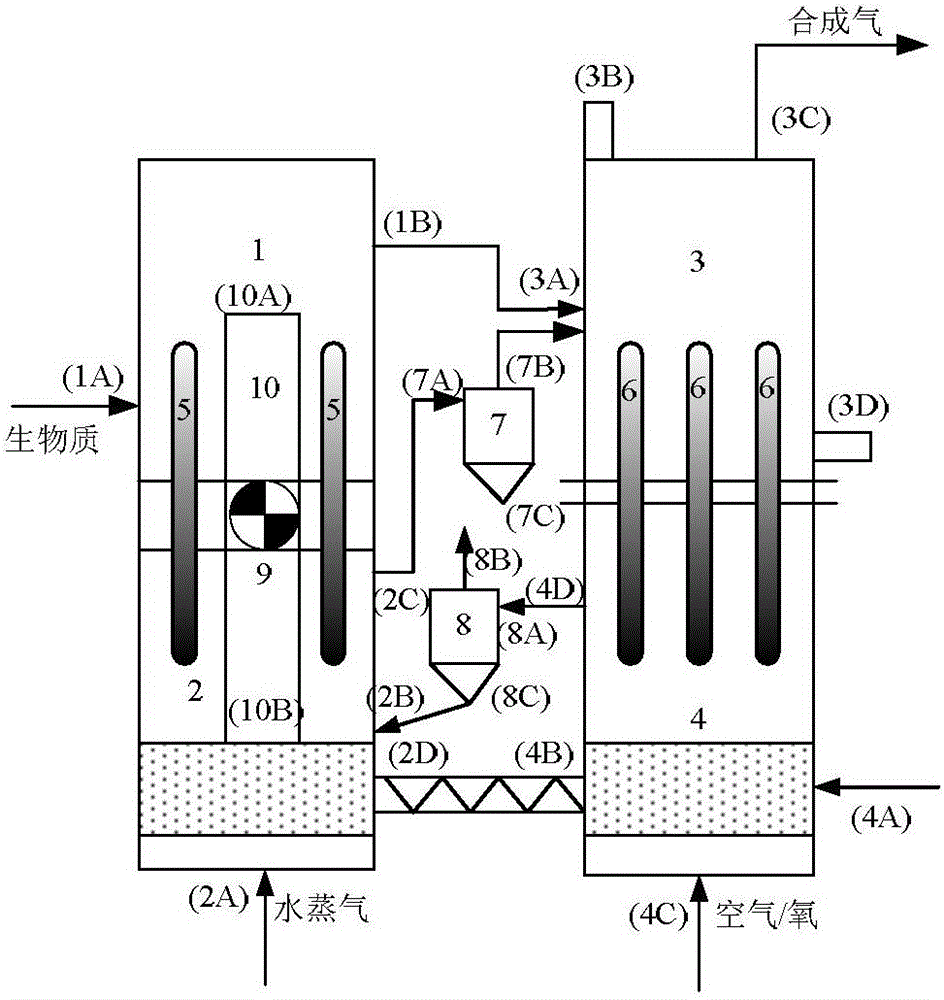

A gasification device and biomass technology, applied in gasification process, chemical modification of combustible gas, purification/transformation of combustible gas, etc., can solve problems such as high tar content, low calorific value of synthesis gas, and difficult conversion and removal. To achieve the effect of increasing added value, avoiding carbon deposition and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Example 1: Wheat Straw Biomass

[0050] Agricultural waste straw is used as raw material, and the gasification process is as above: the wheat straw is broken to about 0.3-0.6mm, and 100gK 2 CO 3 Prepare 2000mL of solution, soak 1000g of crushed wheat straw at room temperature for 1 hour, and then send it to a dryer to dry to a water content below 10%. 700°C, the reforming reaction temperature is 750°C, the combustion reaction temperature is 900°C, the mass ratio of water vapor / wheat straw into the gasification reactor is 0.5, and the circulating bed material is Al 2 o 3 and CaCO 3 / CaO, the ratio of the two is 1:5, CaCO 3 / CaO circulation amount and biomass mass ratio 4:1, reforming catalyst is 15%Ni-3%Li / Al 2 o 3 ; The synthesis gas obtained by gasification reforming, the gas component H after cooling and purification 2 : 65.9%, CO: 19.5%, CO 2 : 14.1%, CH 4 3 / kg, tar 3 , ash K 2 O content -50%.

example 2

[0051] Example 2: Wheat Straw Biomass

[0052] Agricultural waste straw is used as raw material, and the gasification process is as above: the wheat straw is broken to about 0.3-0.6mm, and 150gK 2 CO 3 Prepare 3000mL of solution, impregnate 1000g of crushed wheat straw at room temperature for 1 hour, and then send it to a dryer to dry to a water content below 10%; send the pretreated straw to a pyrolysis reactor with a reaction temperature of 700°C and a gasification temperature of 750°C , the reforming reaction temperature is 750°C, the combustion reaction temperature is 900°C, the mass ratio of water vapor / wheat straw into the gasification reactor is 0.4, and the circulating bed material is Al 2 o 3 and CaCO 3 / CaO, the ratio of the two is 2:1, CaCO 3 / CaO circulation amount and biomass mass ratio 2:1, reforming catalyst is 15%Ni-10%Mg / Al 2 o 3 ; The synthesis gas obtained by gasification reforming, the gas component H after cooling and purification 2 : 60.2%, CO: 24....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com