Ultralow-hardness polyurethane pouring sealant and preparation and application thereof

A potting and polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of long curing time and low application efficiency, and achieve excellent electronic insulation performance, less bubbles, The effect of low mixing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

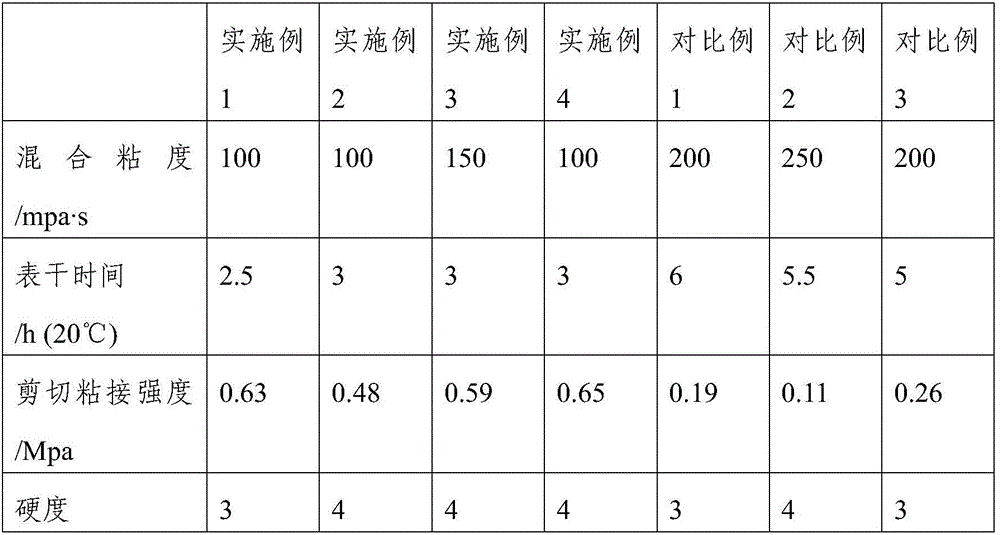

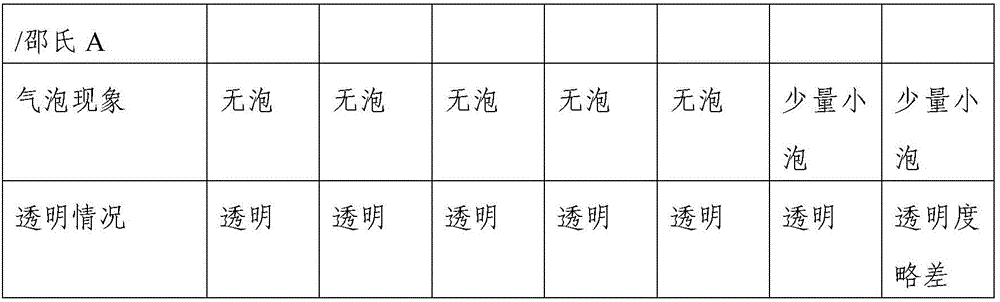

Examples

Embodiment 1

[0026] Embodiment 1 A kind of ultra-low hardness polyurethane potting glue

[0027] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0028] The component A is prepared from the following components by weight: 96.9 parts of castor oil, 0.5 parts of composite anti-yellowing agent, 0.4 parts of catalyst DY-5300, 0.5 parts of catalyst DY-20, and 0.2 parts of defoamer BYK-1794 parts, coupling agent KH-560 1.5 parts;

[0029] The component B is prepared from the following components by weight: 70 parts of plasticizer DOP, 20 parts of SUP2020, and 10 parts of HB 8960B.

[0030] Concrete preparation method comprises the following steps:

[0031] Preparation of component A: Add castor oil into the reaction kettle, vacuumize at 100°C for 3.5 hours to dehydrate to make the water content <0.05%, lower the temperature to 30°C, add 0.4 parts of catalyst DY-5300, 0.5 parts of DY-20, 0.2 parts of foaming agent BYK-1794...

Embodiment 2

[0033] Embodiment 2 A kind of ultra-low hardness polyurethane potting glue

[0034] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0035] The component A is prepared from the following components by weight: 96.4 parts of castor oil, 0.5 parts of composite anti-yellowing agent, 0.6 parts of catalyst DY-5350, 0.3 parts of DY-20, and 0.2 parts of defoamer BYK-1794 , 2.0 parts of coupling agent KH-560;

[0036] The component B is prepared from the following components in parts by weight: plasticizer DOP 70 parts, Sup2020 24 parts, Sup 2439 6 parts.

[0037] Concrete preparation method comprises the following steps:

[0038] Component A: Add 96.4 parts of castor oil into the reaction kettle, vacuumize at 100°C for 3 hours to dehydrate to make the water content <0.05%, cool down to 30°C, add 0.6 parts of catalyst DY-5350, 0.3 parts of DY-20, 0.2 parts of foam agent BYK-1794, 0.5 parts of compound anti-yello...

Embodiment 3

[0040] Embodiment 3 A kind of ultra-low hardness polyurethane potting glue

[0041] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0042] The component A is prepared from the following components by weight: 95.9 parts of castor oil, 0.5 parts of compound anti-yellowing agent, 0.4 parts of catalyst 1619, 0.2 parts of defoamer BYK-066N, and 1.0 parts of coupling agent KH-792 Parts, plasticizer DOP 2 parts,;

[0043] The component B is prepared from the following components in parts by weight: plasticizer DOP 68 parts, Sup2511 32 parts.

[0044] Concrete preparation method comprises the following steps:

[0045] Component A: Add 95.9 parts of castor oil and 2 parts of DOP into the reaction kettle, vacuumize at 100°C for 3.5 hours to dehydrate, make the water content <0.05%, cool down to 25°C, add 0.4 parts of catalyst 1619, defoamer BYK 0.2 part of -066N, 0.5 part of compound anti-yellowing agent, 1.0 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com