Technological system and technological method for extracting glutathione

A technology of glutathione and extraction process, applied in the field of glutathione preparation, can solve problems such as enzyme liquid residue and subsequent process influence, and achieve the effects of large adsorption capacity, alleviation of environmental protection pressure, and strong sample purification and processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

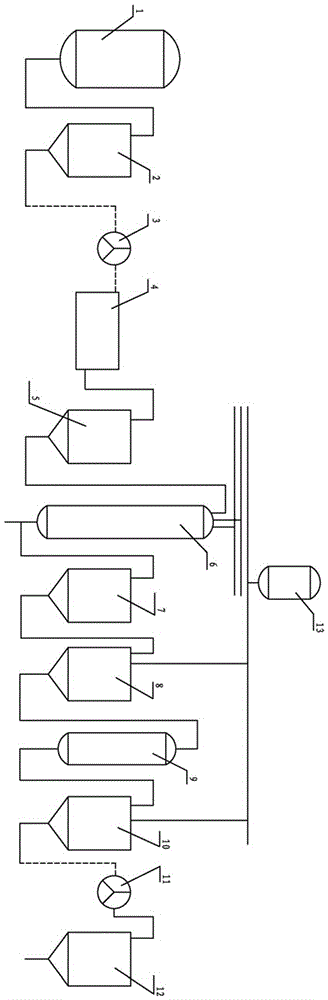

[0030] A glutathione extraction process system, equipment arranged from upstream to downstream, including reactor 1, first material tank 2, first centrifuge 3, filter equipment 4, second material tank 5, resin column 6, The third material tank 7, the fourth material tank 8, the decolorization tank 9, the crystallizing tank 10, the second centrifuge 11, the fifth material tank 12, and also include an organic solvent tank 13, which are respectively located in the tree Refers to the upstream of the column 6, the fourth material tank 8, and the crystallizing tank 10, and is connected by a pipeline;

[0031] Preferably, the organic solvent tank 13 is one of a methanol tank, an ethanol tank, an isopropanol tank, and an acetone tank.

[0032] The extraction process system of glutathione according to claim 1, wherein the filter device 4 is an ultrafiltration device, and the filter membrane pore size of the ultrafiltration device is 8000-10000 Daltons. In this embodiment, the decolori...

Embodiment 2

[0034] A kind of processing method that adopts the extraction process system of above-mentioned glutathione, comprises the steps:

[0035] 1) Preparation of crude GSH: including the following steps:

[0036] 1.1 The material after the reaction of the enzymatic synthesis of glutathione was discharged, the feed liquid was centrifuged to remove insoluble matter, and 55 kg of filtrate was collected;

[0037] 1.2 The obtained filtrate is subjected to ultrafiltration through ultrafiltration equipment, and the ultrafiltration dialysate is collected;

[0038] 1.3 The ultrafiltration dialysate was adjusted to acid and then applied to resin column 6; the diameter-to-height ratio of resin column 6 was 0.05, the pH value of the sample was 2.0, the sample volume was 8mgGSH / ml resin, and the sample flow rate was 0.5bv / h;

[0039] 1.4 Rinse the macroporous resin column with 1bv of purified water at a speed of 0.5bv / h;

[0040] 1.5 Elute and desorb the macroporous resin column with 50% etha...

Embodiment 3

[0049] 1) Preparation of crude GSH: including the following steps:

[0050] 1.1 The material after the reaction of the enzymatic synthesis of glutathione was discharged, the feed liquid was centrifuged to remove insoluble matter, and 55 kg of filtrate was collected;

[0051] 1.2 The obtained filtrate is subjected to ultrafiltration through ultrafiltration equipment, and the ultrafiltration dialysate is collected;

[0052] 1.3 The ultrafiltration dialysate was adjusted to acid and then applied to the resin column; the diameter-height ratio of the resin column was 0.2, the pH value of the sample was 3.5, the sample volume was 20mgGSH / ml resin, and the sample flow rate was 1.5bv / h;

[0053] 1.4 Rinse the macroporous resin column with 3bv of purified water at a speed of 1.5bv / h;

[0054] 1.5 Elute and desorb the macroporous resin column with 95% ethanol at a speed of 2.0bv / h, and collect the ninhydrin chromogenic part of the eluent;

[0055] 1.6 Depressurize the collected eluent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com