Ceramic glazing vacuum compensation machine

A ceramic and vacuum technology, applied in the field of technical ceramic glazing vacuum compensator and ceramic glazing vacuum compensator, can solve the problems of high defective rate, high cost, low efficiency, etc., and achieve simple structure, wide application range and convenient manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

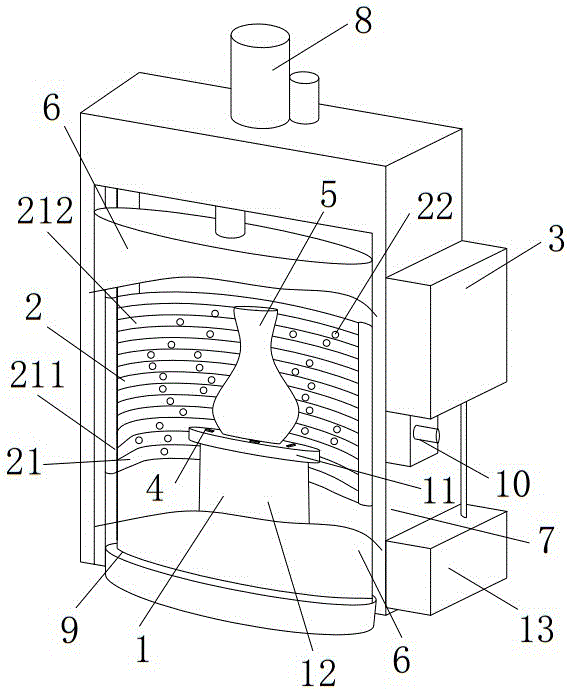

[0020] Such as figure 1 As shown, the vacuum compensator for ceramic glazing includes a rotary support table 1, a glaze spray compensator 2, a control panel 3 and several gravity sensors 4, ceramic products 5 are placed on the rotary support table 1, and the rotary support table 1 includes a horizontal support workbench 11 and a rotating part 12, the horizontal support workbench 11 is provided with several evenly distributed gravity sensors 4, at least one gravity sensor 4 is arranged on the center position of the horizontal support workbench 11; and the control panel 3 is connected to each gravity sensor separately 4 and the glaze spray compensator 2, the control panel 3 acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com