Plate washer with double cleaning heads

A cleaning head and plate washer technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as difficult cleaning, improve cleaning efficiency, improve liquid holding capacity, Reduce the effect of cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

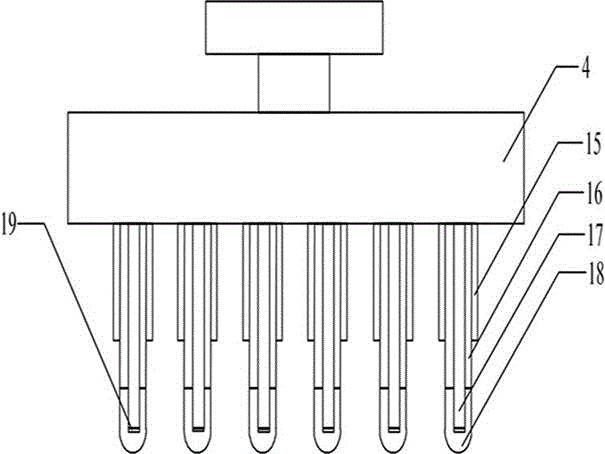

[0032] Such as figure 1 As shown, the present invention is equipped with a plate washer with double cleaning heads, including a first cleaning head 7, a lifting device 3 and a plate washer cavity 5, and the first cleaning head 7 is provided with a liquid injection pipe 8 and a suction pipe 9. The main difference from the microplate plate washing machine of the prior art is that it also includes a second cleaning head 4, and the second cleaning head is provided with a cleaning brush 18, which is conducive to thoroughly removing the impurities adhered in the wells of the microplate plate .

[0033] Such as figure 2 As shown, the second cleaning head 4 is provided with a cleaning pipe 15, and the inside of the cleaning pipe 15 is provided with a rotating shaft 16. The pipe 17 protrudes from the end port of the rotating shaft 16. The lower end of the rotating shaft 16 is provided with a cleaning brush 18. The rotating shaft 16 can drive the cleaning brush 18 to perform a rotat...

Embodiment 2

[0039] Such as figure 1 As shown, on the basis of the structure of Example 1, it also includes a protective cover for cleaning the microplate plate. On the protective cover 11 for cleaning the microplate plate, a number of overflow-proof extension tubes 10 are arranged, and the upper and lower ends of the overflow-proof extension tube 10 are open. , the number and position of the anti-overflow extension tube 10 are in one-to-one correspondence with the number and position of the upper plate holes of the microplate (6), and the lower port of the anti-overflow extension tube 10 can be in sealing contact with the orifice of the microplate 6 plate hole , such as using O-rings. The enzyme label plate 6 is placed on the tray 12, and the enzyme label plate cleaning protection cover 11, the enzyme label plate 6 and the tray 12 are sequentially pasted and fixed by the fixing clips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com