Closed porous ceramic composite material and its preparation method and application

A technology of porous ceramics and composite materials, used in structural parts, electrical components, battery pack parts, etc., can solve the problems of loss of ion-conducting effect of the separator, unsatisfactory application effect, and high oil absorption value, and reduce sedimentation defects and thickness. Requires thin, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

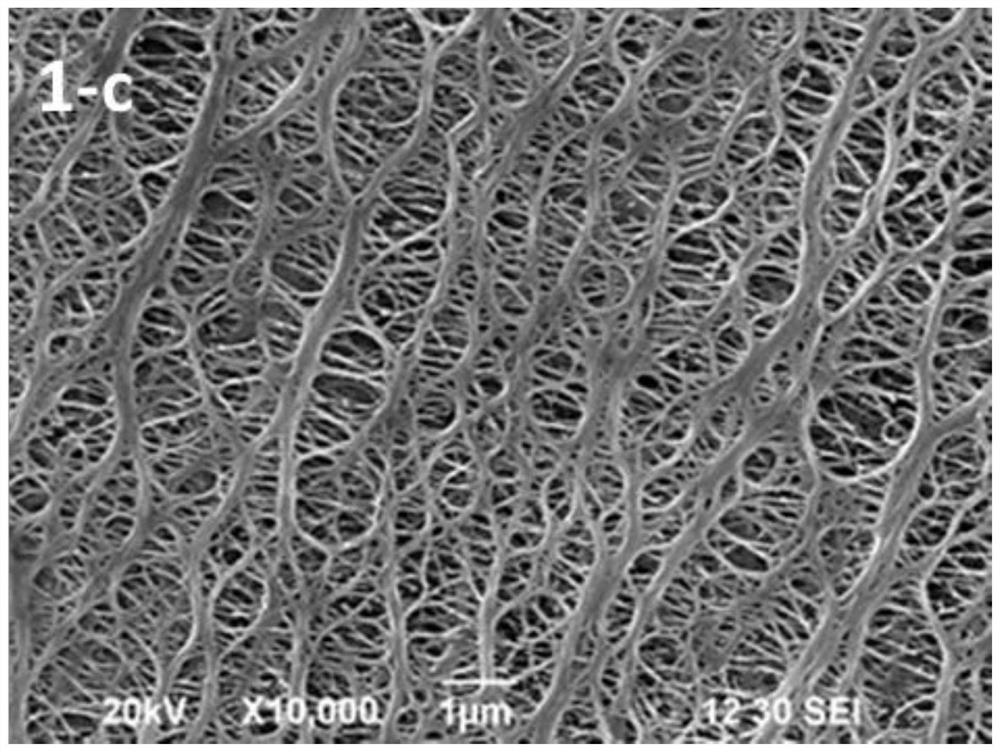

[0057] The invention provides a preparation method and application of a porous ceramic isolation membrane. The porous ceramic isolation membrane uses porous ceramic powder as an inorganic filler.

[0058] By pre-closing the porous structure of the porous ceramic separator before preparing the slurry, the amount of adhesive can be reduced when preparing the slurry, and then the porous ceramic-coated separator is leached to remove the closed cells. The agent regains the porous ceramic structure, thereby improving the liquid-carrying performance of the separator, and at the same time can promote the thinning of lithium-ion batteries and improve the safety performance of lithium-ion batteries, which is conducive to expanding the application scenarios of lithium-ion batteries.

[0059] In the preferred ceramic isolation membrane prepared by porous ceramic powder in the present invention, a ceramic coating whose main component is porous ceramic powder is coated on the membrane.

[0...

Embodiment 1

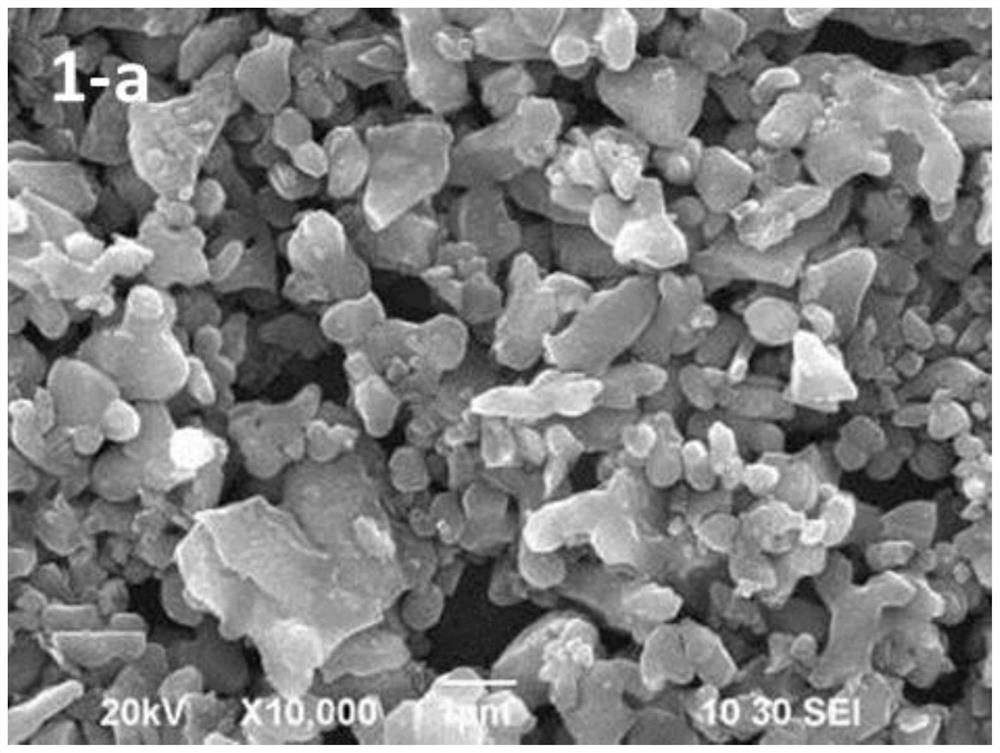

[0084] Take by weighing 42.3kgα type aluminum oxide (D v50 : 0.2μm, Al 2 o 3 α-Al in powder 2 o 3 Content: 95%; Al 2 o 3 The powder accounts for the dry matter content of the coating composition on the diaphragm: 92.09wt%) into a 100L kneader, and under stirring, add 3.2kg of bis(2-ethylhexyl) phthalate (DEHP) and rotate at a speed of Stir at 40 rpm for 30 min to obtain closed porous ceramic composite material 1#.

[0085] Take 70kg of deionized water and add it to a 200L double planetary mixing tank with cooling circulating water, then add 1.5kg of sodium carboxymethylcellulose and 0.5kg of polyvinylidene fluoride (Solef6020) powder to fully disperse and dissolve, and the dissolution is complete Finally, add the composite material 1# into the mixing tank and continue to stir for 60min, then adjust the rotating speed to 20rpm, add 3.4kg of styrene-butadiene latex (solid content 48wt%) and stir for 30min, and obtain the slurry for coating after filtering through a 200-mes...

Embodiment 2

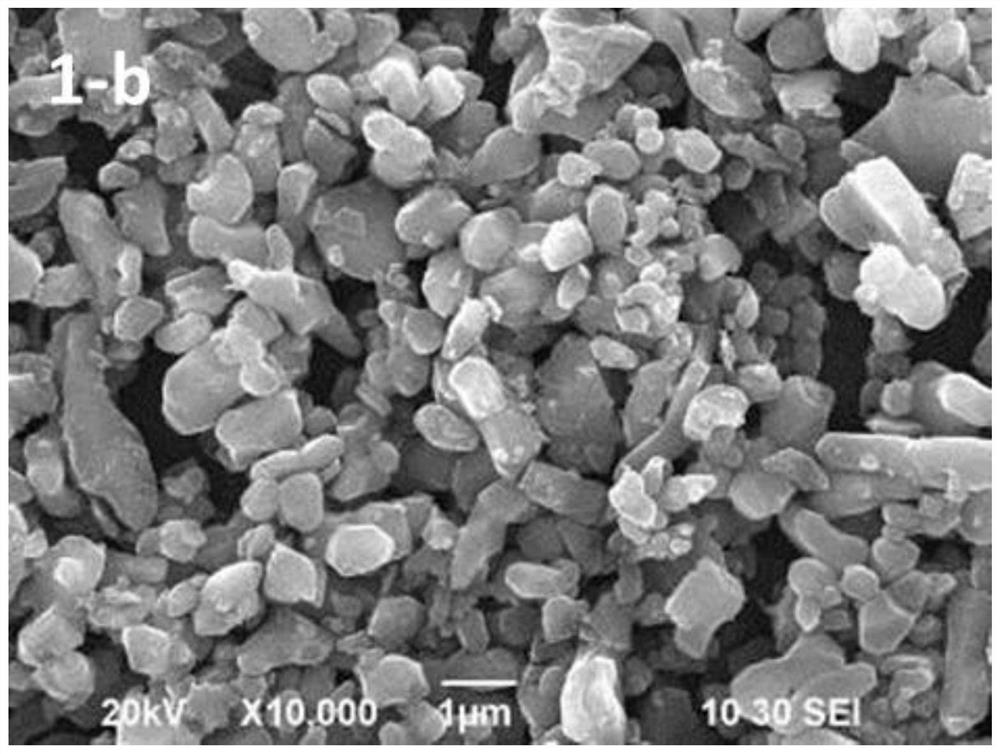

[0088] Weigh 55.8kg gamma type aluminum oxide (D v50 : 1.8 μm, γ-Al 2 o 3 Content: 97%; Al 2 o 3 Powder accounts for the dry matter content of the coating composition on the diaphragm: 92.14wt%) in a 100L fusion machine, then add 4.3kg of dioctyl phthalate (DOP) cell-closing agent, open the fusion machine and disperse for 20 minutes, and the closed cell is obtained. Porous ceramic composite material 2#.

[0089] Take 79kg of deionized water and add it to a 200L double planetary mixing tank with cooling circulating water, then add 1.9kg sodium carboxymethylcellulose and 0.7kg polyvinylidene fluoride (KYNAR 761) powder to fully disperse / dissolve, After the dissolution is complete, add the composite material 2# to the stirring tank and continue to stir for 90min, then adjust the rotating speed to 20rpm, add 4.5kg of styrene-butadiene latex and stir for 30min to obtain the slurry for coating after filtering through a 200-mesh screen. The diaphragm pump is introduced into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com