Back flushing device for fluidized granulator filter and back flushing method thereof

A technology of fluidized granulation and backflushing equipment, which is applied in the direction of chemical instruments and methods, dispersed particle filtration, separation methods, etc., and can solve the problems of increasing the overall energy consumption of equipment, consuming manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

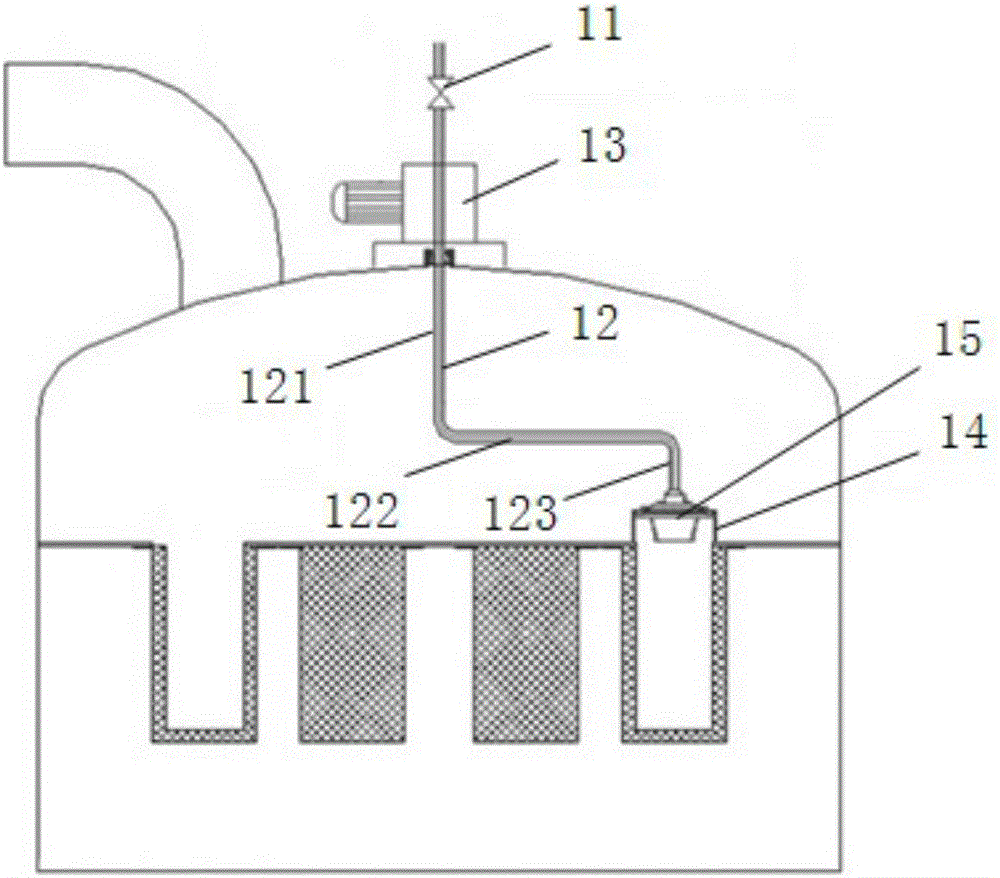

[0039] figure 1 A structural schematic diagram of a backflushing device for a fluidized granulator filter provided in an embodiment of the present invention; figure 1 As shown, the backflushing device of a fluidized granulator filter provided in this embodiment includes: a compressed air control valve 11 connected to a compressed air generating device, a compressed air pipeline 12, a rotary indexing motor 13 and a sealing device 14;

[0040] The compressed air control valve 11 is connected to the compressed air pipeline 12, the rotary indexing motor 13 controls the rotation of the compressed air pipeline 12, the compressed air pipeline 12 drives the rotation of the sealing device 14, and the sealing device 14 is used to seal the filter The chamber is sealed.

[0041] One end of the compressed air pipeline 12 is connected to the compressed air control valve 11, and the other end of the compressed air pipeline 12 is connected to the sealing device 14. There may be multiple sea...

Embodiment 2

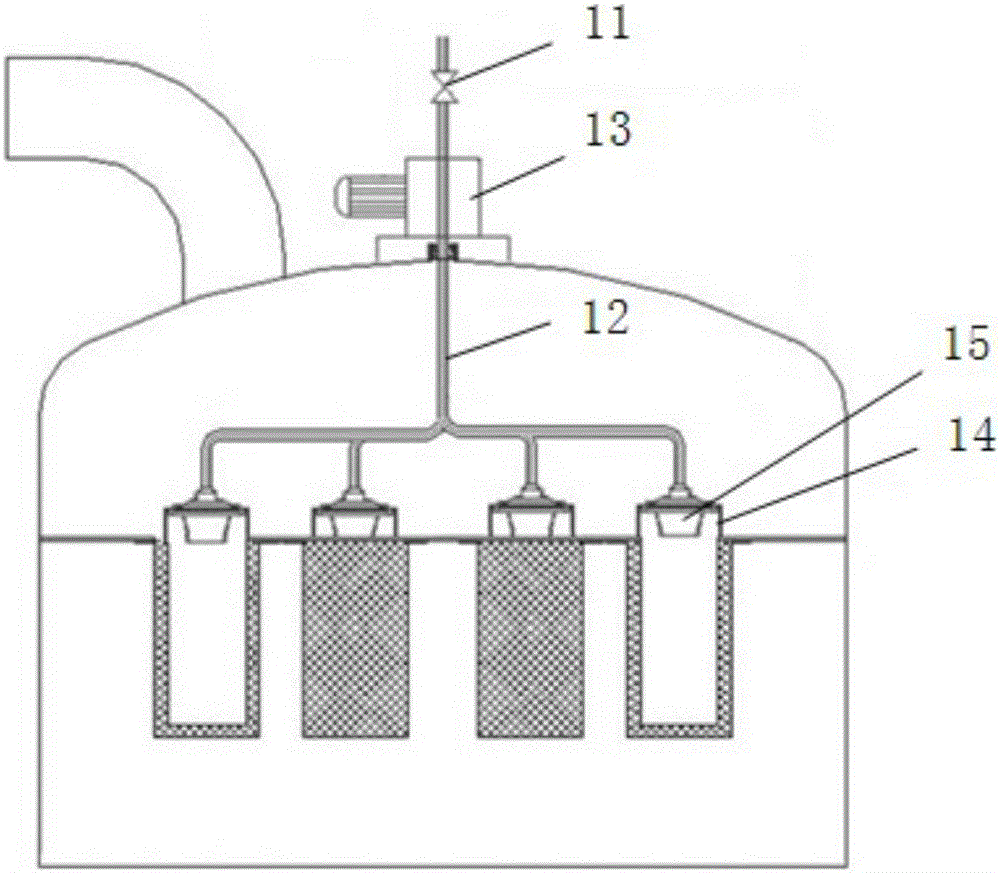

[0061] figure 2 A structural schematic diagram of a backflushing device for a fluidized granulator filter provided in another embodiment of the present invention; figure 2 As shown, the backflushing device of a fluidized granulator filter provided in this embodiment includes: a compressed air control valve 11 connected to a compressed air generating device, a compressed air pipeline 12, a rotary indexing motor 13 and a sealing device 14;

[0062] The compressed air control valve 11 is connected to the compressed air pipeline 12, the rotary indexing motor 13 controls the rotation of the compressed air pipeline 12, the compressed air pipeline 12 drives the rotation of the sealing device 14, and the sealing device 14 is used to seal the filter The chamber is sealed.

[0063] The difference between this embodiment and Embodiment 1 is that the compressed air pipeline 12 is set to have a pipeline inlet in the upper part and a disc shape with multiple pipeline outlets in the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com