Brush Production Device, Brush Body Holder And Method For Producing A Brush

A technology of a holder and a brush body, which is applied in the field of brush manufacturing and can solve problems such as adjustment cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

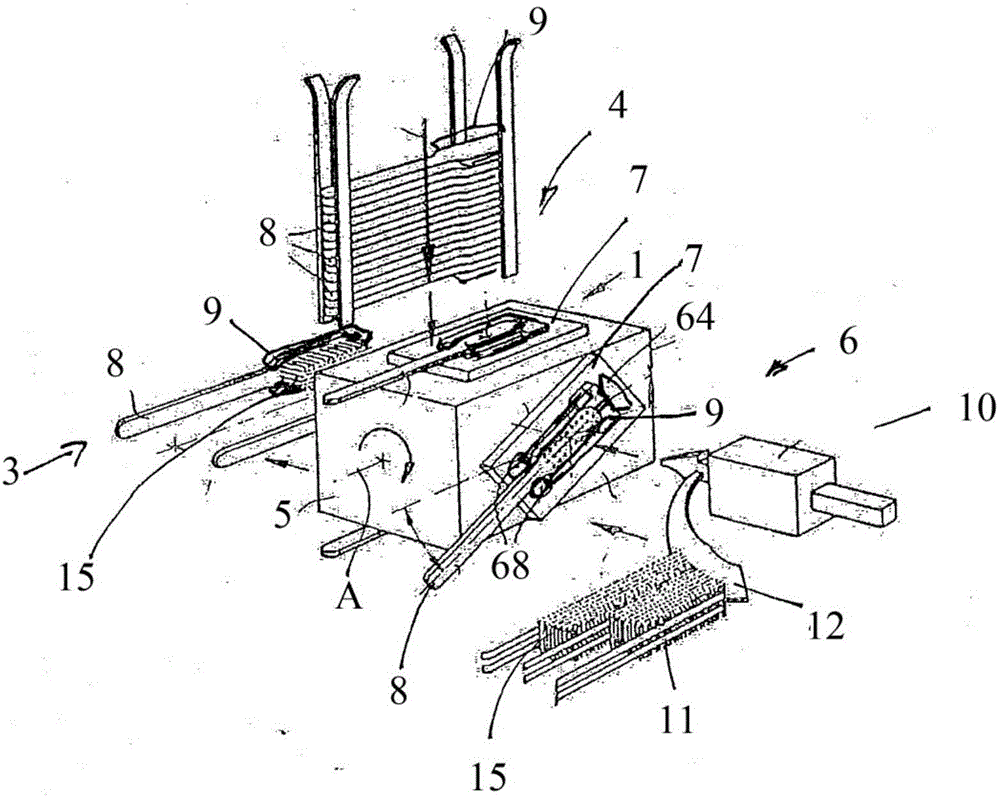

[0058] figure 1 A brush-making device 1 is shown, which in the present example can carry out various processing steps, which are not to be understood as restrictive. The brush-making device has, for example, a receiving table 5 which is rotatable.

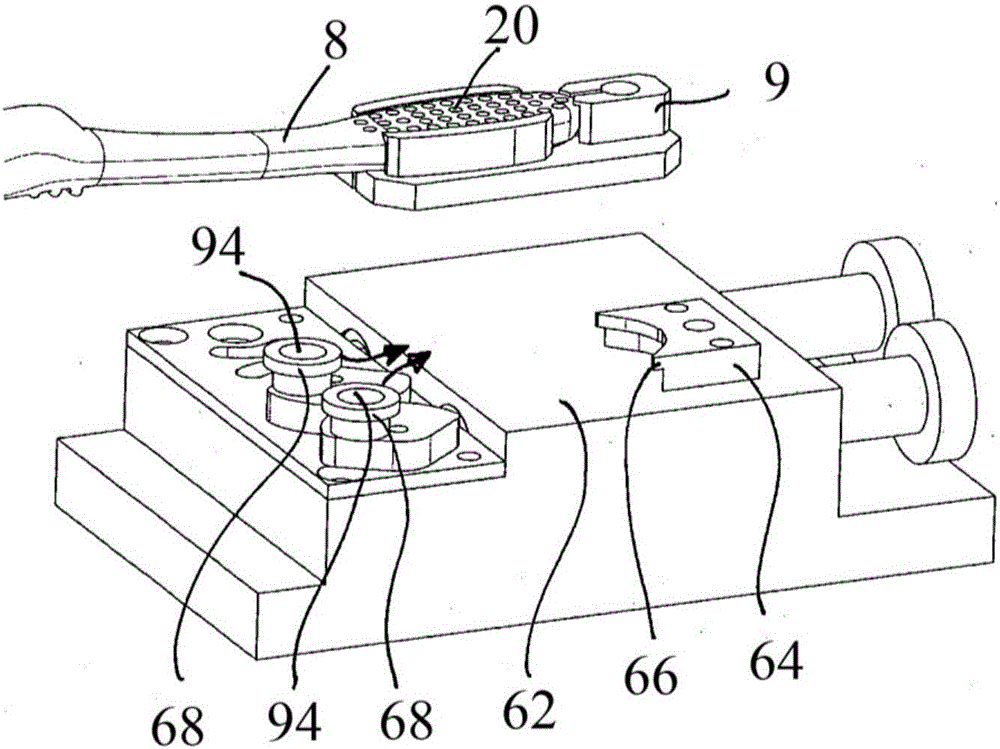

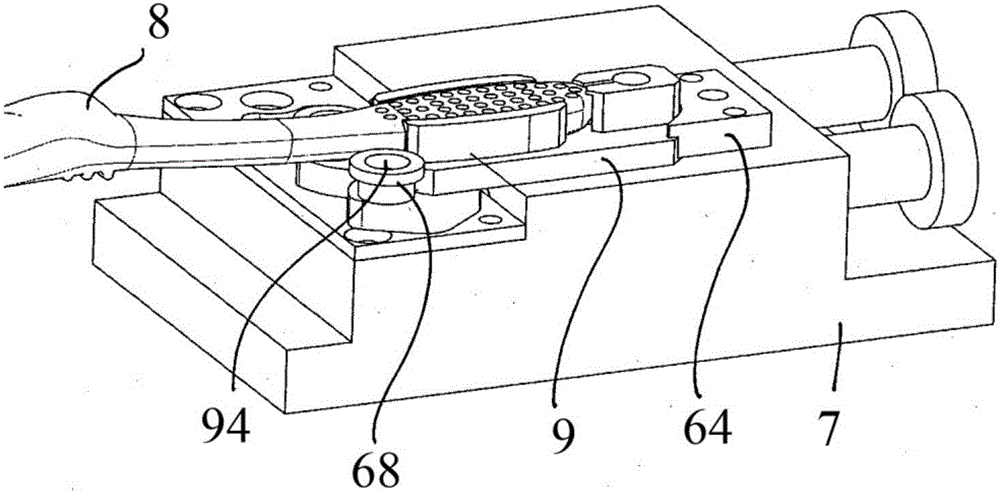

[0059] The receiving table is basically a cube which can be rotated about an axis A between four positions. The unit consisting of a brush body 8 and a brush body holder 9 accommodated in the positioning unit 7 sits on its side. In four different positions, different processing steps, which are processing stations, take place.

[0060] In the uppermost position, a filling station 4 is realized. In this case, the unit consisting of the brush body 8 and the brush body holder 9 is inserted into the free positioning unit 7 . In particular, this takes place fully automatically. The illustrated embodiment is only simplified.

[0061] In a subsequent step (turned clockwise by 90°), the packing takes place in the packing station, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com