Actuating handle

A technology for operating handles and operating components, which is applied in the field of operating handles and can solve problems such as expensive assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the description that now follows, the same reference numerals designate the same components or the same features, so that in order to avoid repeated descriptions, the description of the components with respect to the figures also applies to the other figures.

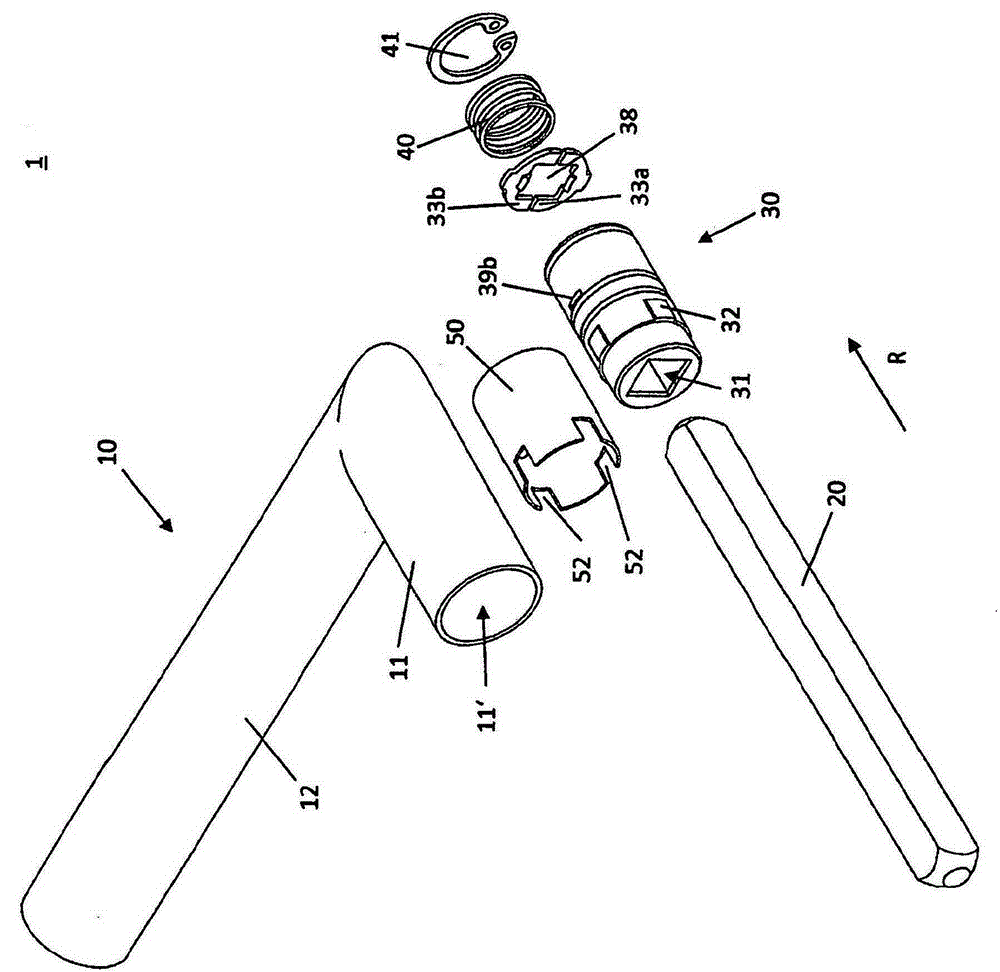

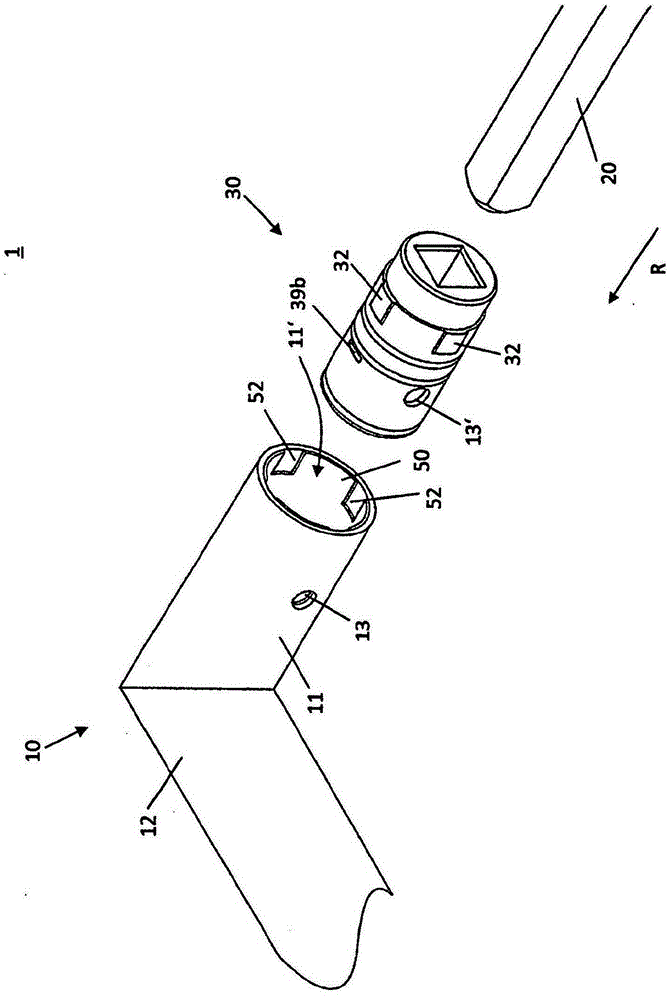

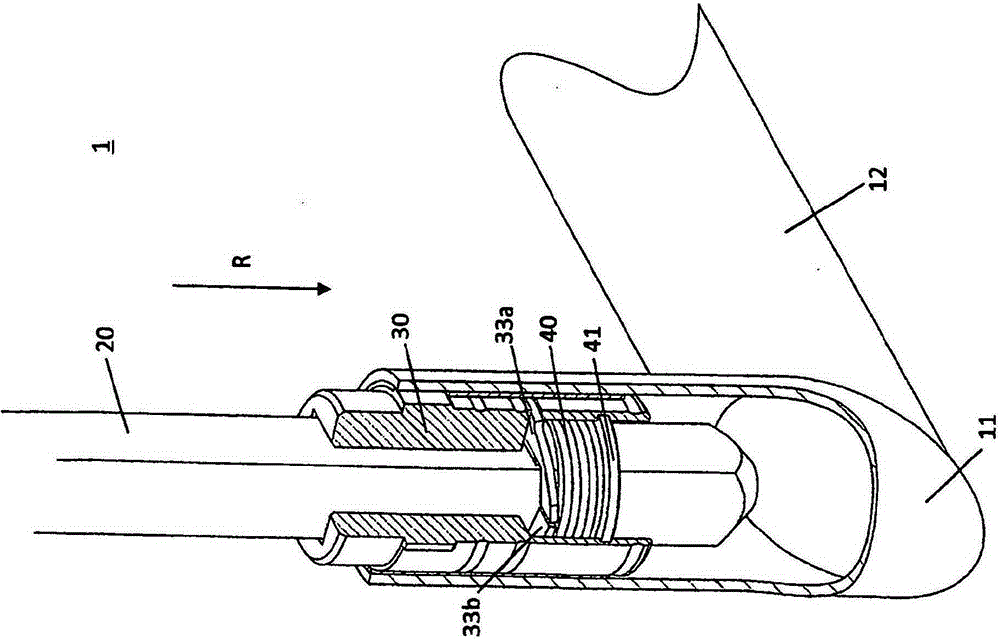

[0026] Depend on figure 1 and 2 It can be seen that the construction of the joystick 1 according to the invention, wherein, in figure 1 shows the joystick 1 in the disassembled state, while in figure 2 shows the joystick in a partially assembled state. The operating handle 1 comprises an actuating part 10 which, in the exemplary embodiment shown, is designed as a door handle 10 with a neck section 11 and a handle section 12 . The neck section 11 is hollow and has a recess 11 ′ for receiving the fastening sleeve 50 and the receiving sleeve 30 .

[0027] The receiving sleeve 30 has a receiving opening 31 for receiving the driver element 20 . In the exemplary embodiment shown, the entraining element 20 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com