Pesticide composition containing fluazaindolizine

A technology of triflumidamide and pesticide composition, which is applied in biocides, animal repellents, plant growth regulators, etc., can solve the problems of plundering host plant nutrition, restricting agricultural economic development, and yield loss, and achieves The effect of reducing the number of medications, reducing adverse effects, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: Indoor toxicity assay

[0018] According to Sun Yunpei's method, the synergistic effect of drug mixture is evaluated according to the co-toxicity coefficient (CTC), that is, CTC≤80 is synergistic antagonism, 8050 / EC of test agent 50 ) × 100; Theoretical toxicity index TTI = the toxicity index of A agent × the percentage content of A agent in the mixture + the toxicity index of B agent × the percentage content of B agent in the mixture; co-toxicity coefficient (CTC) =[Actual Toxicity Index (ATI) of Mixture / Theoretical Toxicity Index (TTI) of Mixture]×100.

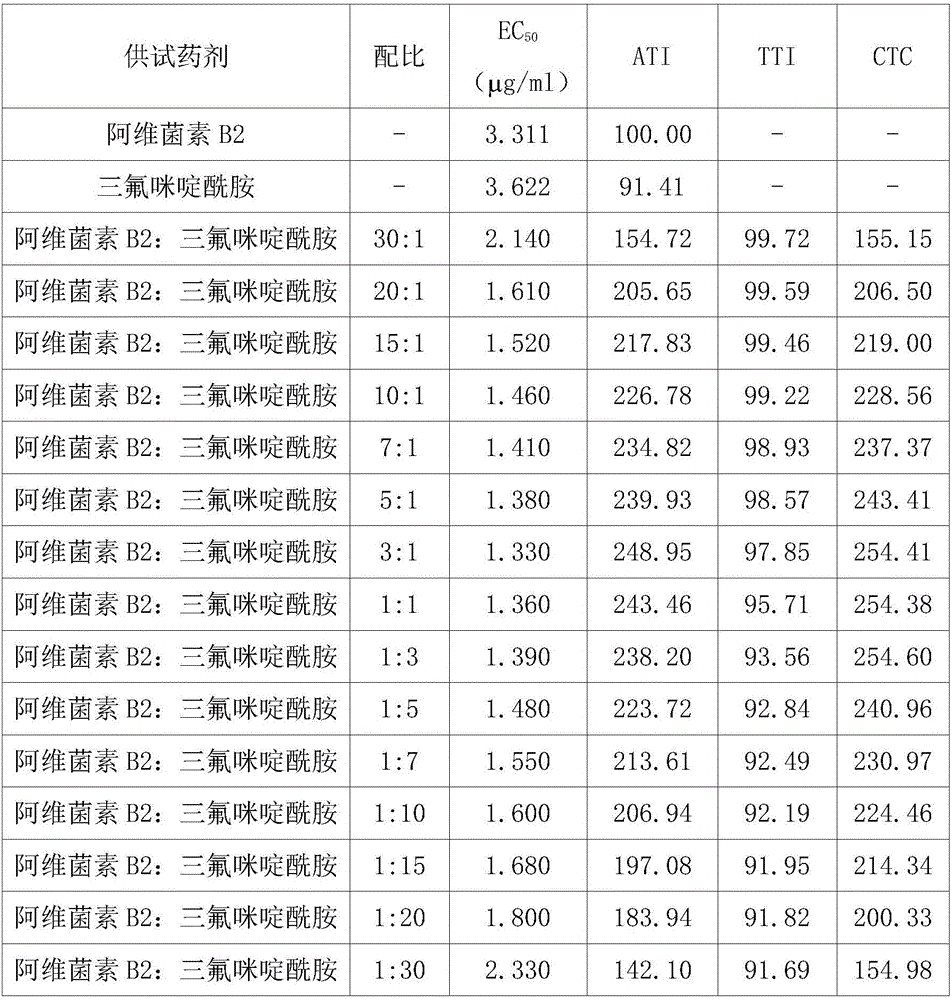

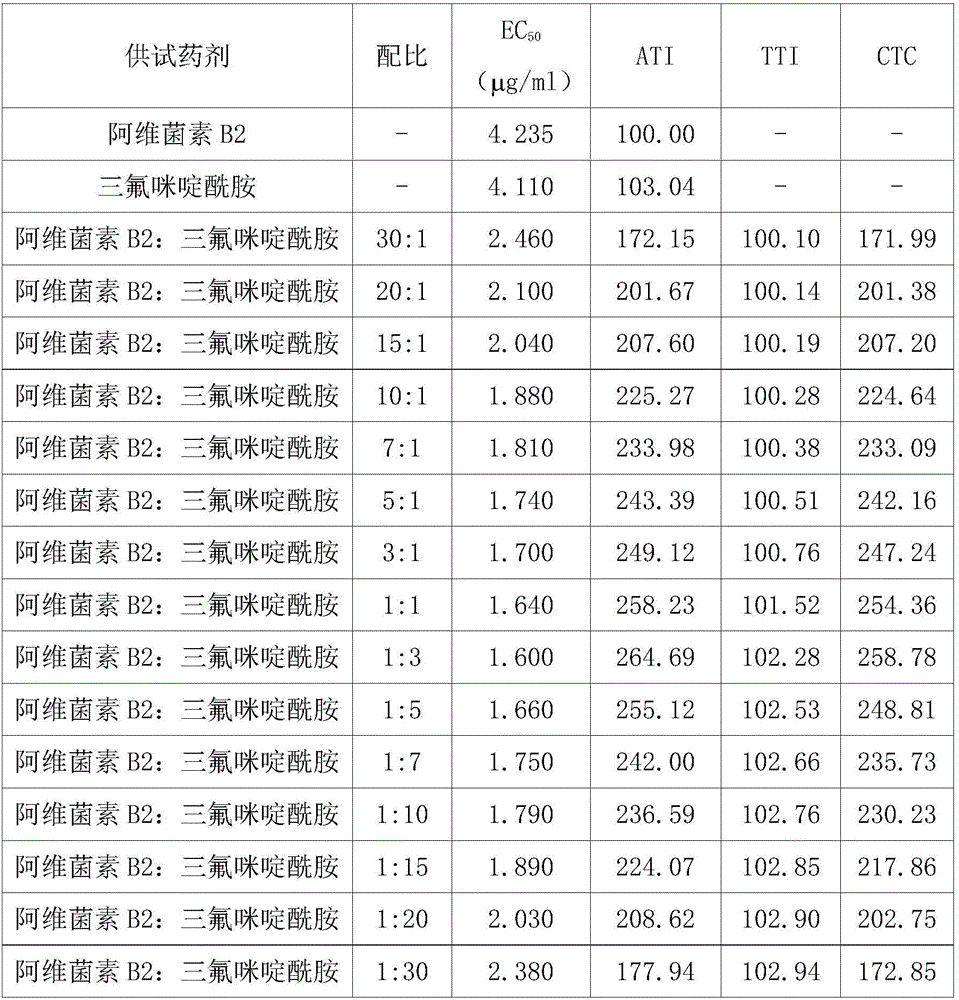

[0019] 1. Indoor toxicity determination of abamectin B2 triflumid against root-knot nematode (Meloidogyneincongnita Chitwood), the test object was collected from the galls of cucumber root-knot nematode disease in the field and separated by Berman funnel. Meloidogyne incongnita Chitwood.

[0020] Table 1. Laboratory toxicity test results of Abamectin B2 Triflumid against Meloidogyne incongnita Chit...

Embodiment 2

[0045] Embodiment 2: 12% Abamectin B2. Triflumidazolamide Microcapsule Suspension

[0046] The following materials are all in weight ratio: Weigh 2% Abamectin B2 original drug, 10% triflumidazolamide original drug, dissolve in 15% 600# solvent oil, add 1.5% Nongru 33# and 7% bismuth Phenylmethane diisocyanate, stir and mix evenly to form an oil phase; add 7% polyvinyl alcohol aqueous solution to an appropriate amount of water and stir to form a water phase; mix the oil phase and water phase, and use a high-shear emulsifier at 10,000 rpm Shear emulsification to form a uniform emulsion. Slowly and evenly add 1% glycerol into the emulsion with stirring at 500 rpm. After 80 minutes, the dropwise addition is completed. React in a water bath at 25°C and stir at 500 rpm for 4 hours, then heat up Cured at 60°C for 2 hours, then added 2% gum arabic aqueous solution, 1% polycarboxylate dispersant and 4% ethylene glycol, adjusted the pH to be neutral, and added 100% by weight with deioni...

Embodiment 3

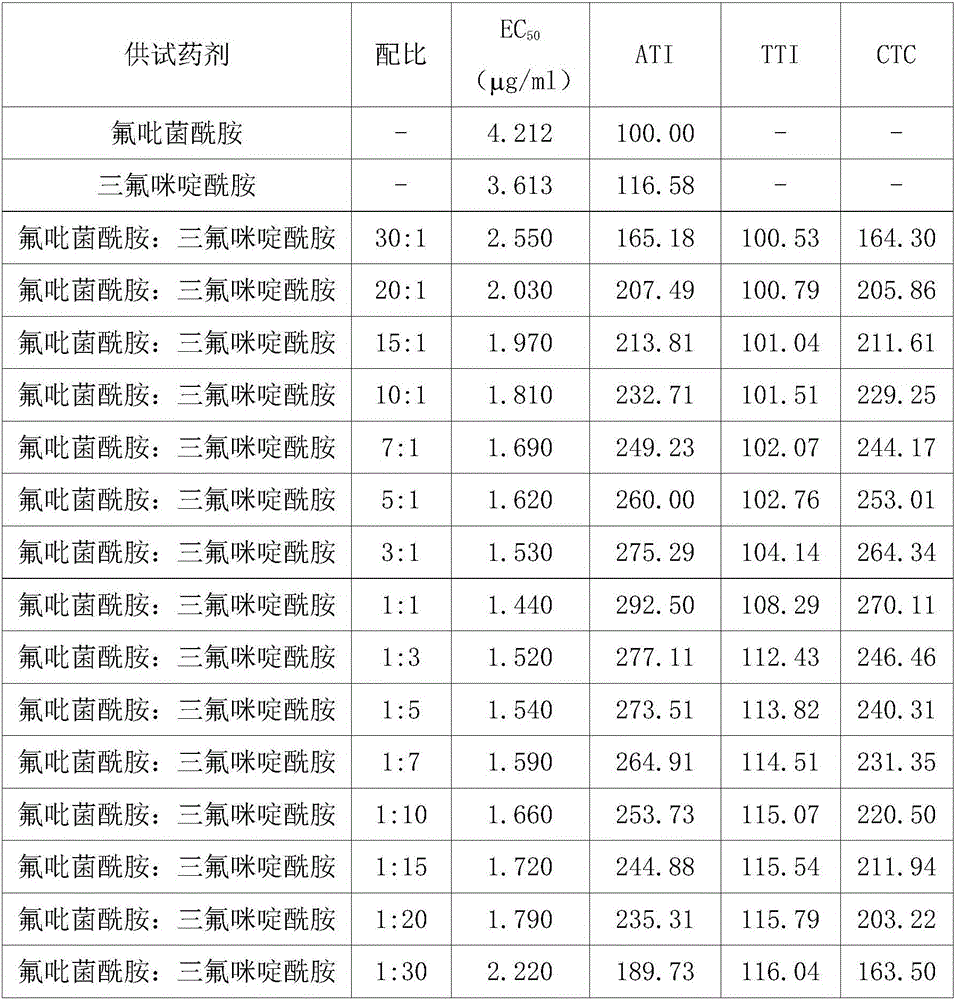

[0048] Example 3: 22% Fluopyram B2 Triflumid Microcapsule Suspension

[0049] The following substances are all in weight ratio: Weigh 2% fluopyram original drug and 20% triflumidazolamide original drug, dissolve them in 15% 600# solvent oil, add 2% agricultural milk 33# and 5% diphenyl Methyl methane diisocyanate, stir and mix uniformly to form an oil phase; add 10% polyvinyl alcohol aqueous solution to an appropriate amount of water and stir to form a water phase; mix the oil phase and water phase, and use a high-shear emulsifier to shear at 10,000 rpm Cut and emulsify to form a uniform emulsion. Slowly and evenly drop 1% ethylenediamine into the emulsion under stirring at 500 rpm. After 40 minutes, the dropwise addition is completed. React for 4 hours in a water bath at 25°C and stir at 500 rpm, and heat up to Curing at 60°C for 2 hours, then add 1% aqueous gum arabic solution, 2% polycarboxylate dispersant, 1% alkylphenol polyoxyethylene ether and 4% ethylene glycol, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com