Permanent magnet direct current energy adding motor

A permanent magnet DC and permanent magnet technology, which is applied in the field of permanent magnet DC energy-enhanced motors, can solve the problems of complex rotor armature structure, lack of magnetization effect, and low utilization rate, so as to improve the air gap magnetic field strength, increase and enhance The utilization level of permanent magnets and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

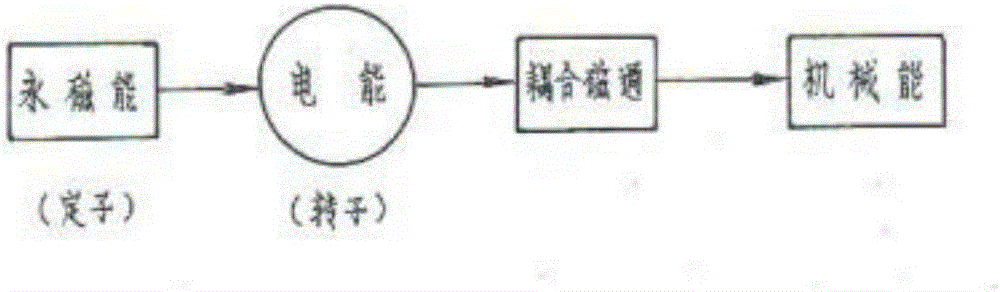

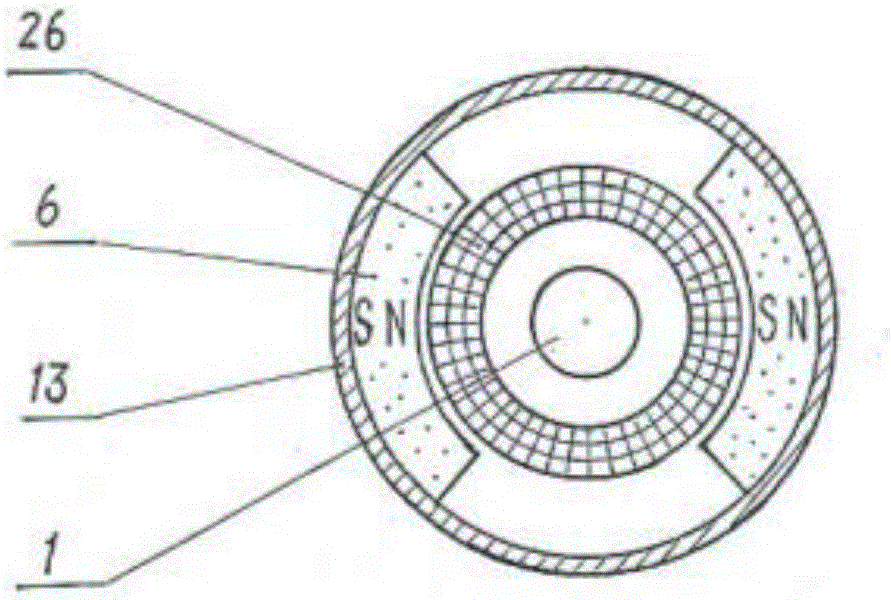

[0055] The permanent magnet DC energy-enhanced motor of the present invention adopts electronic commutation (brushless control) such as Figure 5-6 As shown: It consists of a casing 13, a permanent magnet energy generator stator pole assembly fixedly connected in the casing, a permanent magnet rotor unit, a bearing, a front end cover, a rear end cover, and electronic commutation system components connected thereto;

[0056] Among them, the stator pole assembly of the permanent magnet energy generator includes a magnet core 5 which is stacked and riveted by silicon steel sheets, the middle part of the magnet core is embedded with a winding 7, the large end face of the magnet core is pasted with a stator permanent magnet 6, and the stator permanent magnet is radially charged. Magnetism, magnetic field direction see Image 6 The middle mark is arranged side by side according to the magnetic accumulation structure. The above-mentioned parts constitute the stator pole unit of the p...

Embodiment 2

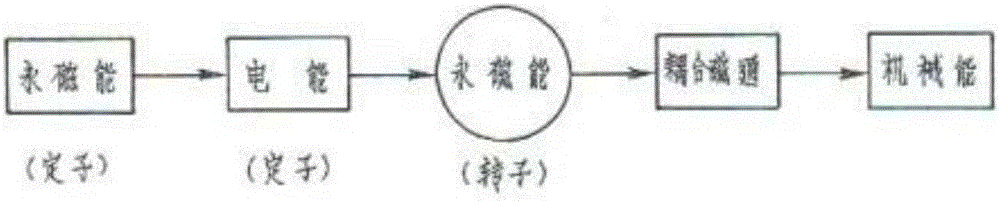

[0063] The permanent magnet DC energized motor of the present invention is as Figure 8-9 Shown; Including casing 13, permanent magnet energy generator stator pole assembly, permanent magnet rotor unit, bearing 2, front end cover 15, rear end cover 10 and the mechanical commutation (with brush control) system components;

[0064] Among them, the stator pole assembly of the permanent magnet energy generator includes: the magnet core 5 is stacked and riveted by silicon steel sheets, the middle part of the iron core is embedded with a winding 7, the large end face of the iron core is pasted with the stator permanent magnet 6, and the stator permanent magnet 6 is radially charged. The direction of magnetism and magnetic field is shown in the figure and arranged according to the magnetic accumulation structure. There are six groups of permanent magnet energy generators, which are evenly distributed according to the mechanical angle of 60 degrees. The stator permanent magnets 6 in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com