Color changing process for resin lens

A resin lens and process technology, applied in the field of discoloration, can solve the problems of complex discoloration process, high cost and difficulty, and achieve the effects of uniform discoloration, easy control, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

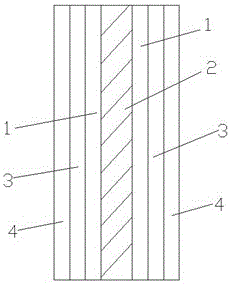

[0019] Such as figure 1 Shown is the structural diagram of the photochromic lens, the lens includes a resin lens 2, a color-changing hard layer 1, an anti-reflection film 3 and a super waterproof film 4, the color-changing hard layer 1 is attached to the surface of the resin lens 2, and the anti-reflection film 3 and the super waterproof film 4 are attached to the surface of the color-changing hardened layer 1 in sequence, that is, the super waterproof film is placed on the outermost layer, and the resin lens 2 includes CR-39 Columbia resin and IPP as well as light stabilizers, dyes and anti-UV Additives; the color-changing and hardening layer 1 is obtained by dissolving the photochromic monomer in a color-changing and hardening liquid.

[0020] The photochromic lens is mainly realized through the following processes:

[0021] Step 1: First, pre-treat the resin lens, which needs to be etched by KOH, ultrasonic cleaning, methylene chloride cleaning, ultrasonic pure water clea...

Embodiment 2

[0032] Such as figure 1 Shown is a structural diagram of a photochromic lens. This rapid change, fade lens comprises resin lens 2, color change hard layer 1, anti-reflection film 3 and super waterproof film 4, described color change hard layer 1 is attached to the surface of resin lens 2, described anti-reflection film 3 and super waterproof film The film 4 is sequentially attached to the surface of the color-changing hard layer 1, that is, the super waterproof film is placed on the outermost layer, and the resin lens 2 includes MR series polyurethane-based monomers and MR series polyisocyanates as well as light stabilizers, dyes and anti-UV Additives; the color-changing and hardening layer 1 is obtained by dissolving the photochromic monomer in a color-changing and hardening liquid.

[0033] The photochromic lens is mainly realized through the following processes:

[0034] Step 1: First, pre-treat the resin lens, which needs to be etched by KOH, ultrasonic cleaning, methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersed particle size | aaaaa | aaaaa |

| Dispersion diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com