Kilometer-depth L-shaped ground pre-grouting drilling tool assembly applied to hole drilling and hole drilling process

A drilling tool assembly and pre-grouting technology, which is applied in the field of mining machinery, can solve the problems of high resistance to rock powder upward return, difficulty in tripping and drilling, and stuck drill, so as to improve drilling efficiency, improve construction quality, and improve drilling efficiency. track smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

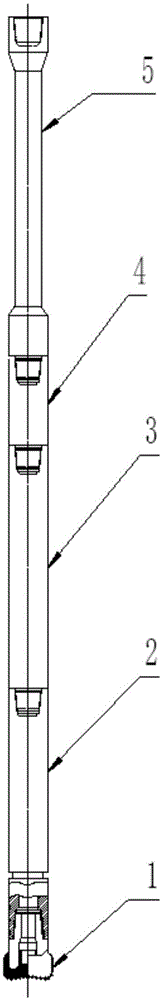

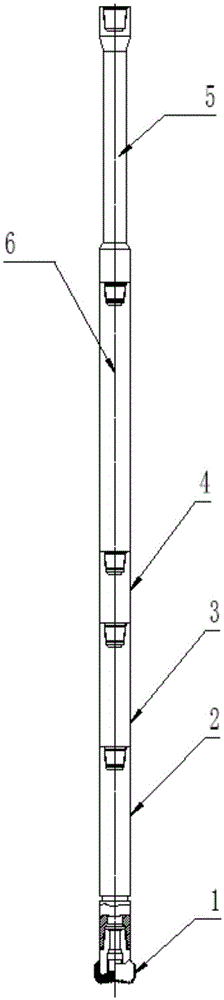

[0026] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0027] Take the L-shaped hole ground pre-grouting reinforcement project of the underground roadway in Xinhu Coal Mine, Guoyang County, Anhui Province as an example.

[0028] In this embodiment, a total of 3606m is drilled, including a total of 1806m in the deflection section and a total of 600m in the horizontal section. in:

[0029] (1) Drilling in straight hole section

[0030] When drilling open holes, the drilling tool assembly used includes Ф215.9mm roller cone bit, Ф159mm drill collar and Ф73mm short drill pipe; the drilling parameters are: drilling pressure 0.3~0.5t; drilling speed: 30~40r / min; Volume: 990L / min; when drilling, the drilling rig rotates slowly at low pressure, and circulates mud with a large displacement to ensure the verticality of the drilling hole.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com