Sealing part for casement

A sealing component and window sash technology, which is applied to the installation of sealing devices and window glass, etc., can solve the problems of affecting the sound and heat insulation effect of the window sash, the separation of the sealing component and the glass, and weakening the sealing effect, so as to increase the heat and sound insulation effect and effectively Good for sealing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

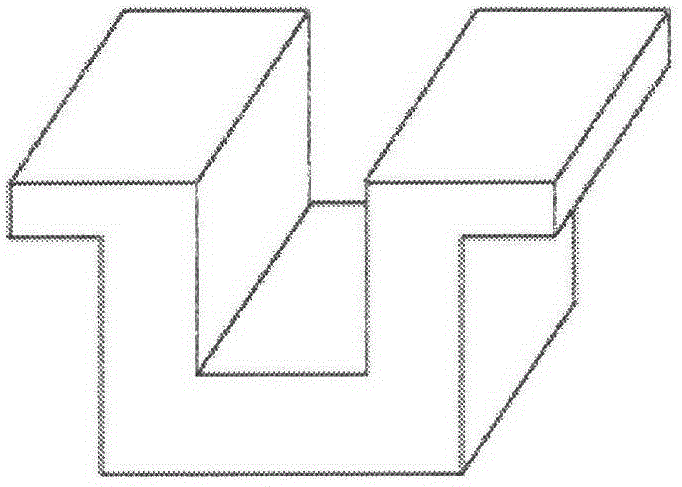

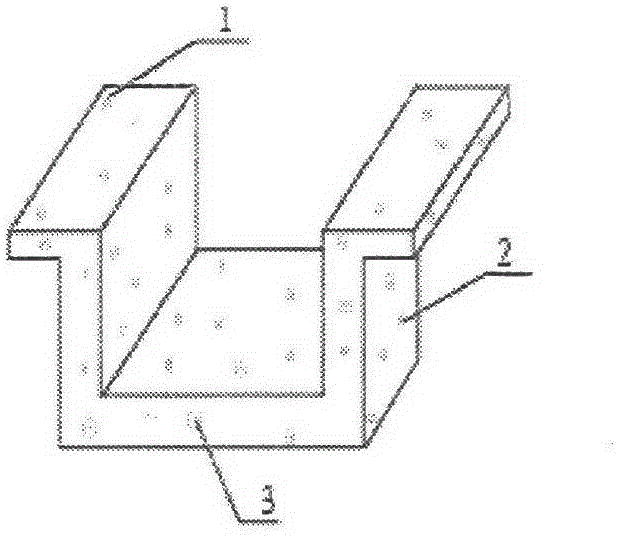

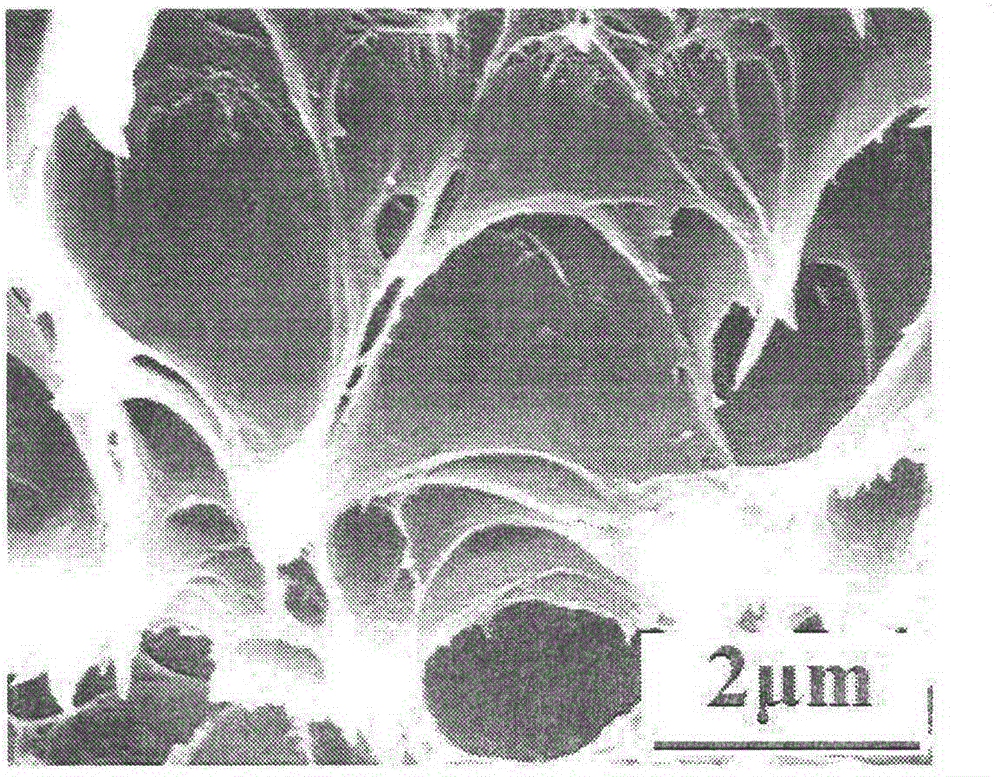

[0030] Embodiment one: see Figure 1-2 As shown, a sealing part for a window sash is a concave structure with flanging, consisting of a core material and a surface material; the core material is wrapped by the surface material; the shape of the core material is consistent with the surface material; The volume of the core material is 80% of the volume of the surface material; the long side of the sealing part is provided with a flanging structure; the core material has a microporous structure; the volume of the micropores is 16-18% of the volume of the core material.

[0031] When polyurea formaldehyde is added to the raw materials for preparing the core material, when the core material is prepared, the polyurea formaldehyde decomposes to generate gas under heating, and the core material thus prepared has a microporous structure. The surface material and the core material are rubber. First prepare two parts of the surface material, and then place the core material between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com