Quick joint early-dismantling jack for construction

A construction and jacking technology, which is applied in the direction of construction, building structure, and on-site preparation of building components. It can solve the problems of high construction cost, low safety performance, and increased material use burden, so as to facilitate early demolition and adaptability. Strong, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

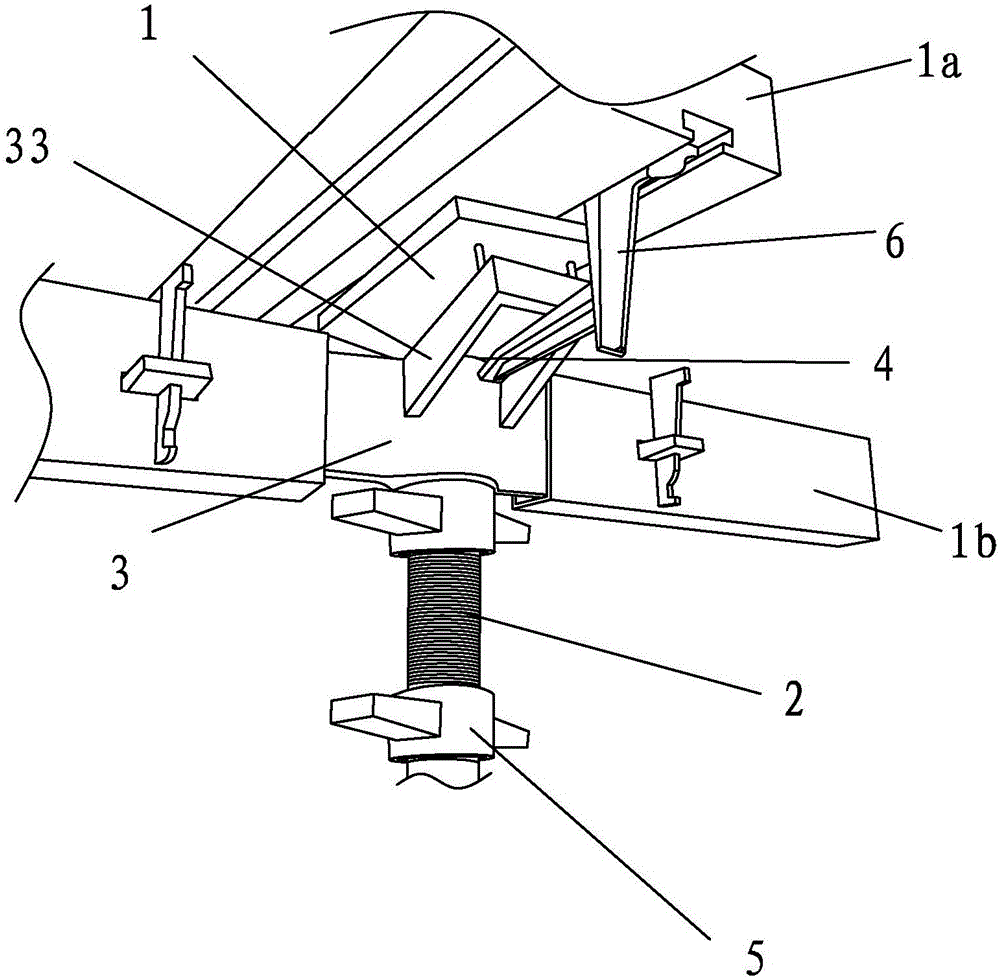

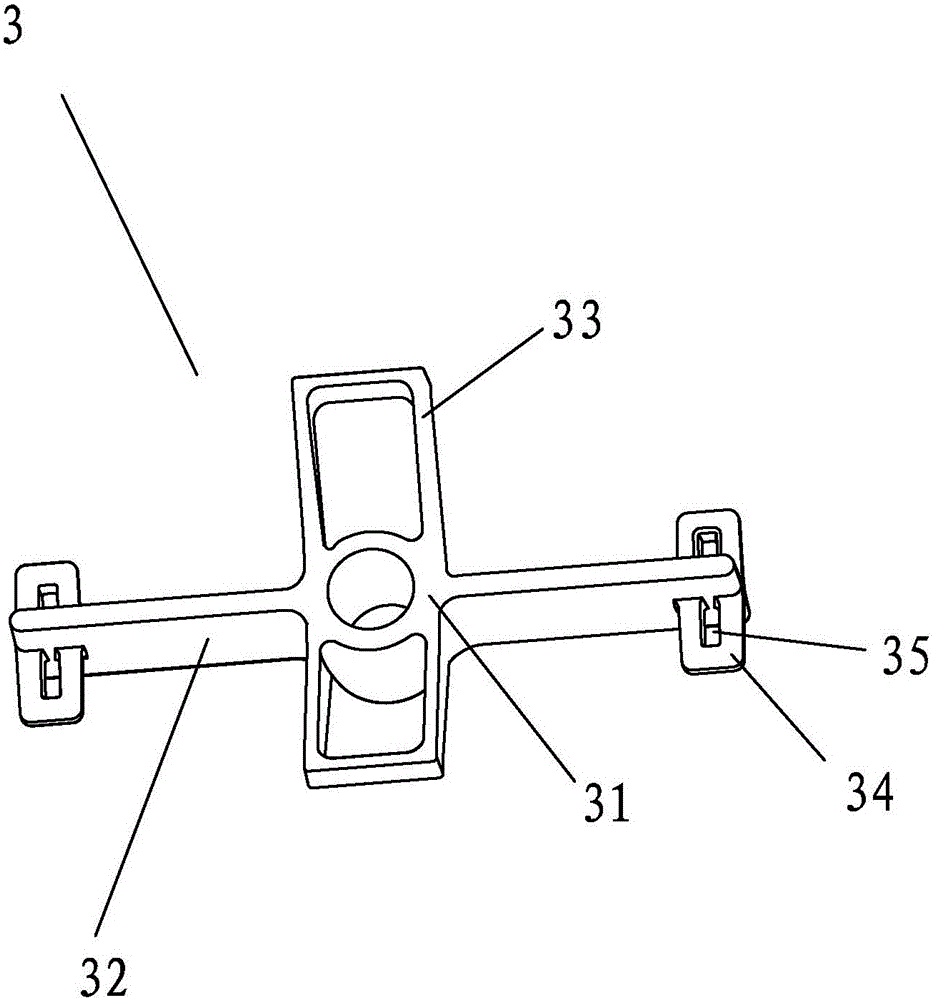

[0041] Such as figure 1 As shown, a quick-connect and early-release jacking bracket for construction has a support plate 1, a support column 2, an early-release bracket 3 and an adjustment device. The support plate 1 is arranged on the support column 2 , and the support plate 1 and the support column 2 are connected together by a hinge structure 4 . Preferably, the supporting column 2 is a screw rod, and the adjusting device includes two adjusting nuts 5 .

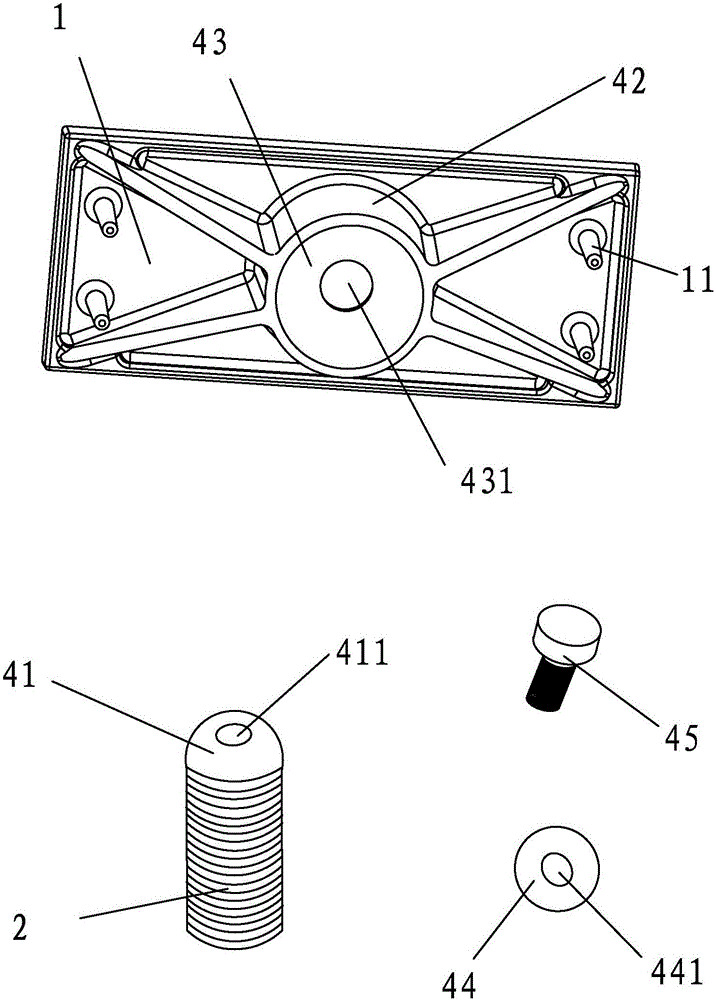

[0042] Such as image 3 As shown, the upper end of the support column 2 is processed into a protruding head 41, the protruding head 41 is in the shape of a spherical surface, the central position of the protruding head 41 is provided with a through hole 411 along the axial direction, and the inner wall of the through hole 1 411 is provided with an internal thread. A boss 42 is connected to the lower side of the support plate 1, and the boss 42 is hollow cylindrical. An axial through hole (not shown) corresponding to the...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that there is a limiter on the support surface 1, such as Figure 5 As shown, in this embodiment, support plates 7 are respectively provided at one set of opposite sides of the support surface 1 . The support nail 11 in the first embodiment is replaced by the support plate 7, the support force of the support plate 7 is stronger, which can prevent the breakage of the support nail 11 during construction and use, and is suitable for building construction systems that require higher bearing capacity .

[0051] The invention provides a quick-connect early-dismantling roof bracket for construction, which is convenient for loading and unloading, and is very suitable for an early-dismantling support system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com