Compound buckled wood floors

A wooden floor and buckle wood technology, which is applied to floors, buildings, building structures, etc., can solve problems such as warping, deformation, mutual extrusion, and gaps that cannot be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

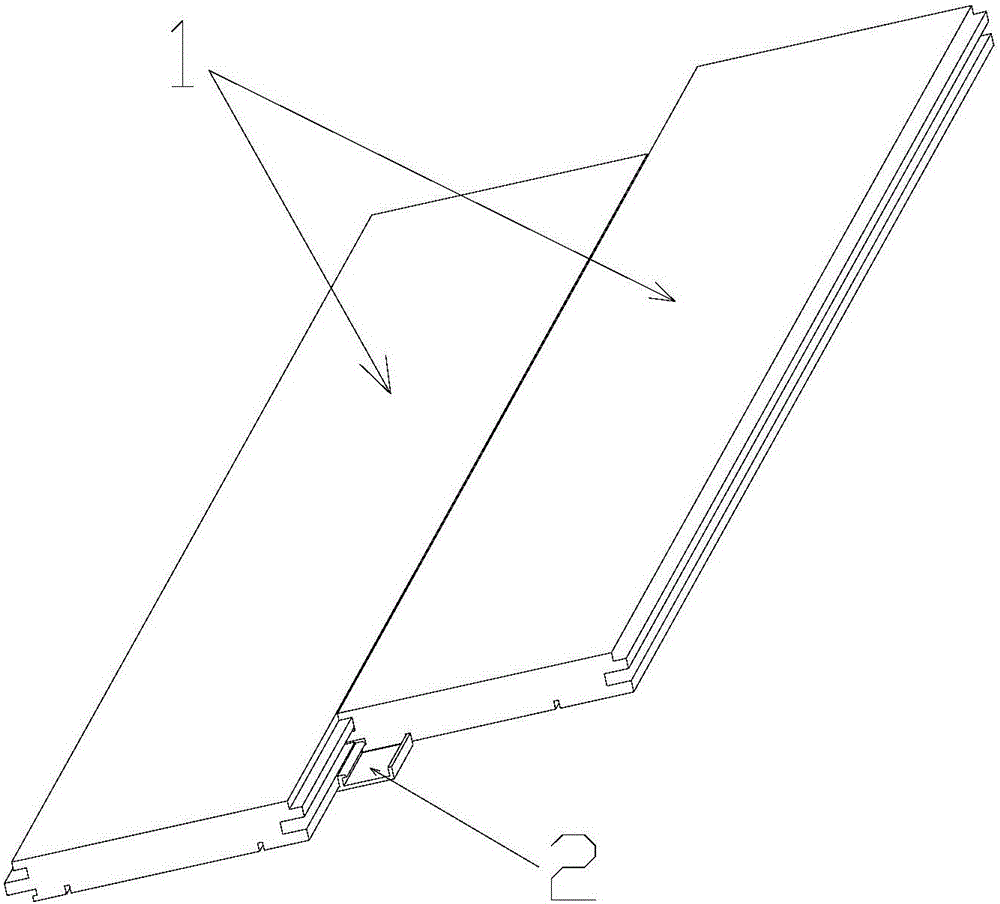

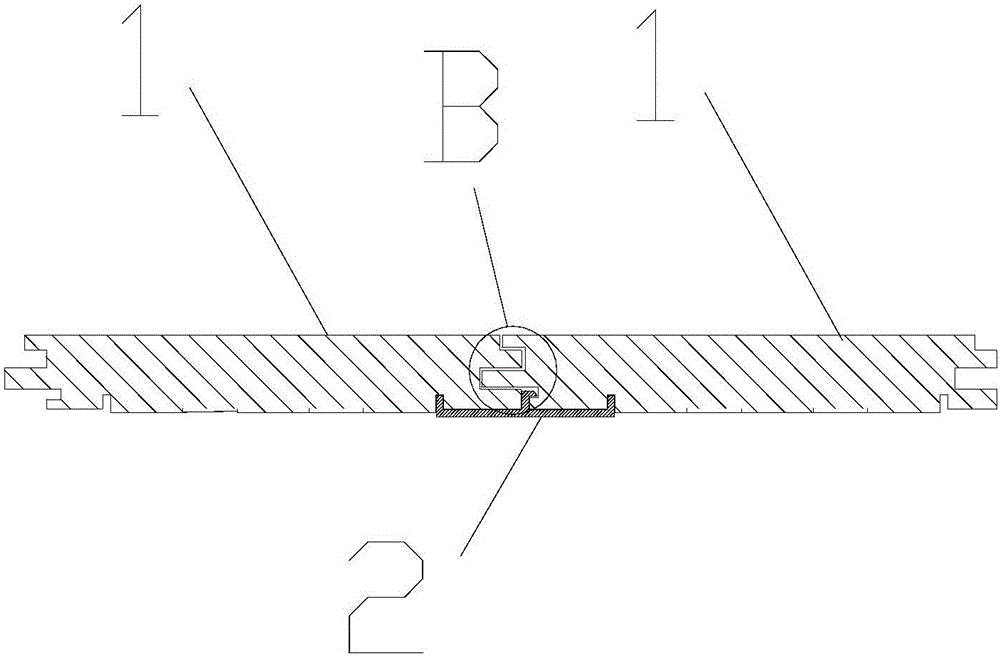

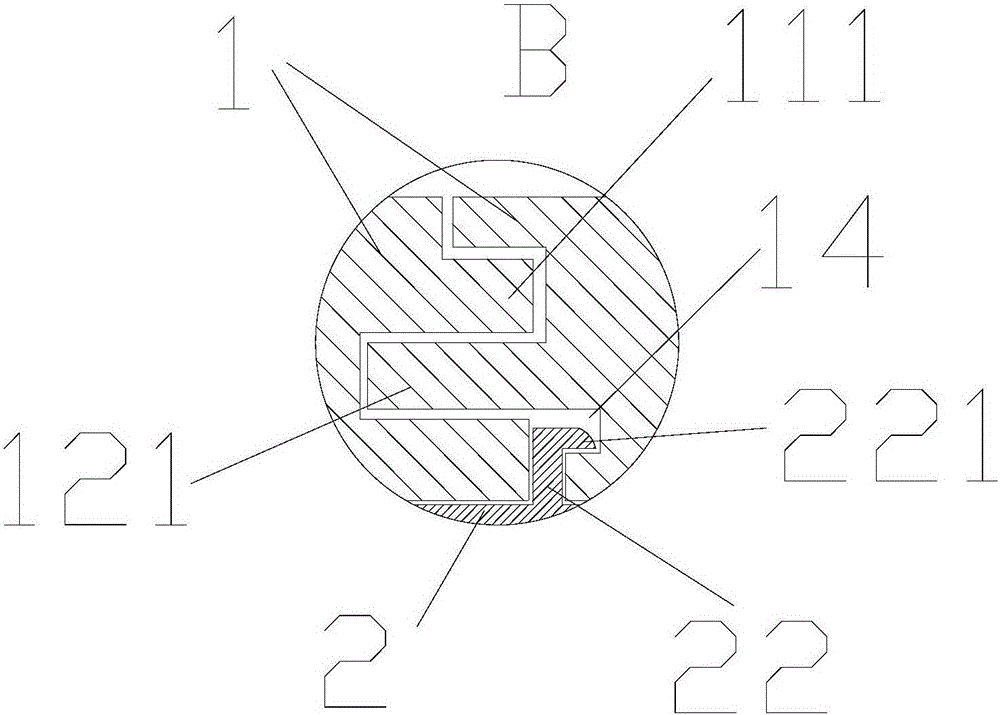

[0030] Figure 1 to Figure 6 Schematically shows a compound buckle wood flooring according to an embodiment of the present invention. As shown in the figure, the device includes a wooden floor 1 and a fastener 2 .

[0031] Wherein, a first groove 11 and a second groove 12 are respectively provided on opposite sides of the wooden floor 1 . After two adjacent wooden floorboards 1 are connected to each other through the first groove 11 and the second groove 12 , the wooden floorboards 1 can move along their lengthwise or widthwise directions.

[0032] The two sides opposite to the back of the wooden floor 1 are respectively provided with slide grooves 13 parallel to the edges thereof.

[0033] In this embodiment, the first tongue and groove 11 includes a first tongue 111 and a first tongue and groove 112 respectively arranged along the thickness direction of the wood floor 1 . Wherein, the first tongue 111 is located above the first tongue groove 112 . The second tongue and g...

Embodiment 2

[0059] Figure 7 Schematically shows a compound buckle wooden floor according to another embodiment of the present invention. As shown in the figure, the difference from Embodiment 1 is that a tongue or a tongue and groove are provided on both sides of the wooden floor 1, thereby forming a single tenon-and-groove structure.

[0060] In this embodiment, an overhead groove 15 is also provided on the back of the wooden floor 1 . The depth of the overhead groove 15 is 2-5 mm, which is used to isolate the main body of the wooden floor 1 from the ground. In this way, a channel for air flow can be formed under the wooden floor 1 , thereby avoiding local accumulation of humidity and temperature under the wooden floor 1 and causing strong deformation of the bottom plate. This kind of wooden floor is especially suitable for installation in an environment with high humidity on the ground or in a place where floor heating is installed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com