Novel ferric trichloride etching solution

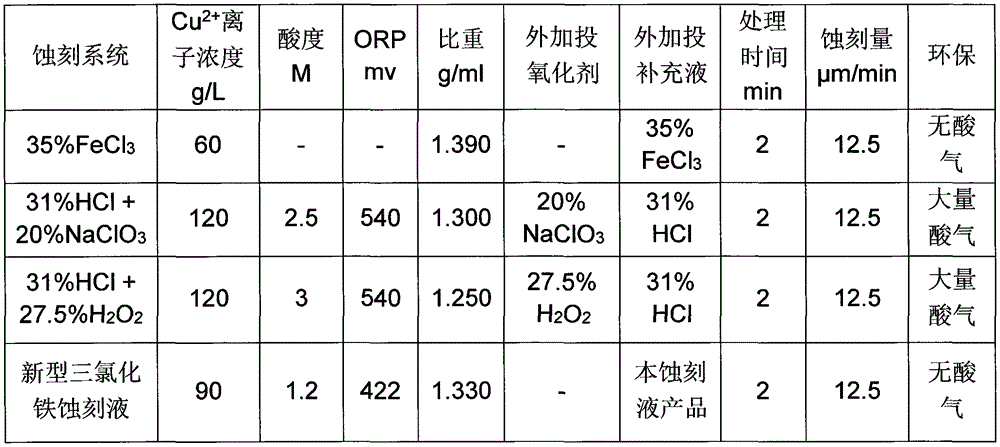

A technology of plate ferric chloride etching and acidic ferric chloride etching, which is applied in the field of chemical mixture solution for acid etching copper, can solve the problems of unstable etching speed, rapid decline of etching speed and high etching rate of the old technology, and achieve High-quality etching process, improved etching quality, and high-quality etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

[0024] 1. Select a circuit board spray etching production line with an automatic detection feeding controller with a pH meter and a hydrometer.

[0025] 2. After calibrating the process parameters of the etching production line controller, set the specific gravity feeding data to 1.330g / ml, and add the sub-liquid (that is, the new ferric chloride etching solution) into the etching solution working cylinder through the specific gravity feeding controller .

[0026] 3. After the above steps are completed, pour the new ferric chloride etching solution into the etching cylinder of the production line, then heat and spray and put copper plates to make the etching working mother solution.

[0027] 4. When the temperature of the working fluid is 48-50°C, the pH value is 1.1-1.4M, and the specific gravity is 1.330g / ml, the circuit board can be put into etching production after adjusting the board speed and other process parameters according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com