Preparation method of large-size high-pure copper flat target material

A high-purity copper and planar target technology, applied in the field of sputtering targets, can solve the problems of easy deformation of large-sized copper targets and large investment in equipment, and achieve the effects of avoiding abnormal tissue growth, low equipment cost, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

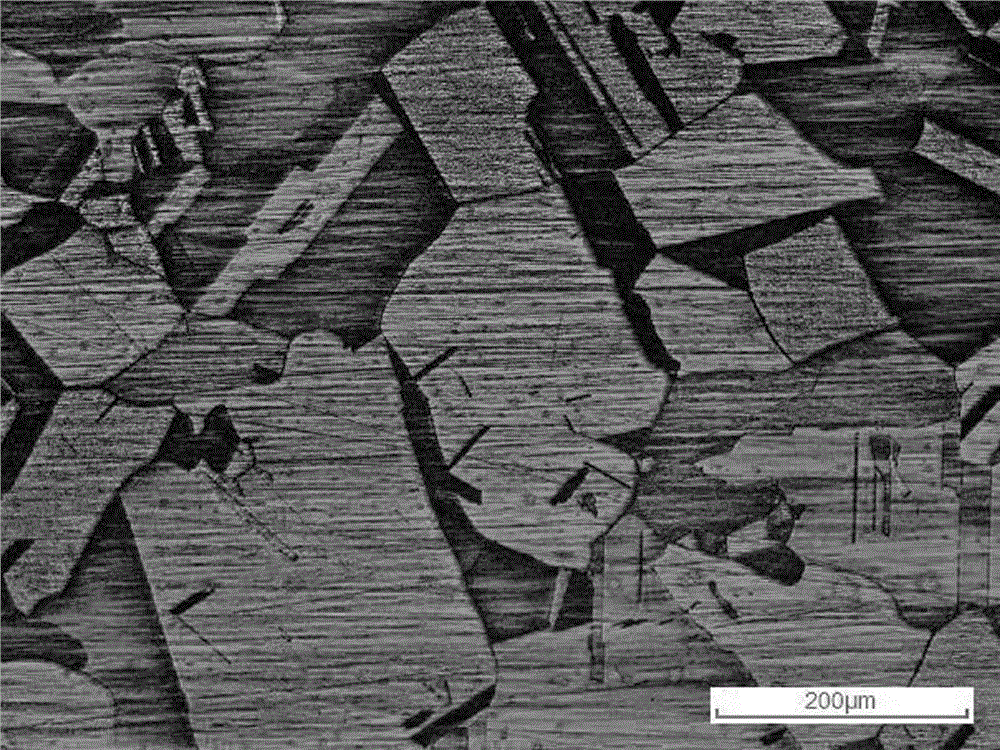

Embodiment 1

[0038] A method for preparing a large-scale high-purity copper planar target, comprising the following steps:

[0039] (1) Heat the cylindrical copper ingot (specification φ200 mm×300 mm, purity 99.99%, hardness HV40) to 600°C for 50 minutes, preheat the air hammer head to 350°C, and firstly Pull out after upsetting, the final size is φ150 mm×400 mm;

[0040] (2) Continue to heat the copper ingot processed in step (1) for 30 minutes, forging three times, each forging 10 times, three forging directions (X, Y, Z directions) are perpendicular to each other, forging until Cuboid copper forging blank, the size of cuboid copper forging blank is 72mm×200mm×840mm;

[0041] (3) Continuously heat the cuboid copper forging billet in step (2) at 300°C for 60 minutes, and cool it to room temperature in the air to realize the first annealing treatment of the copper forging billet;

[0042] (4) Hot-roll the cuboid copper forging billet after the annealing treatment in step (3) on a 300-ton...

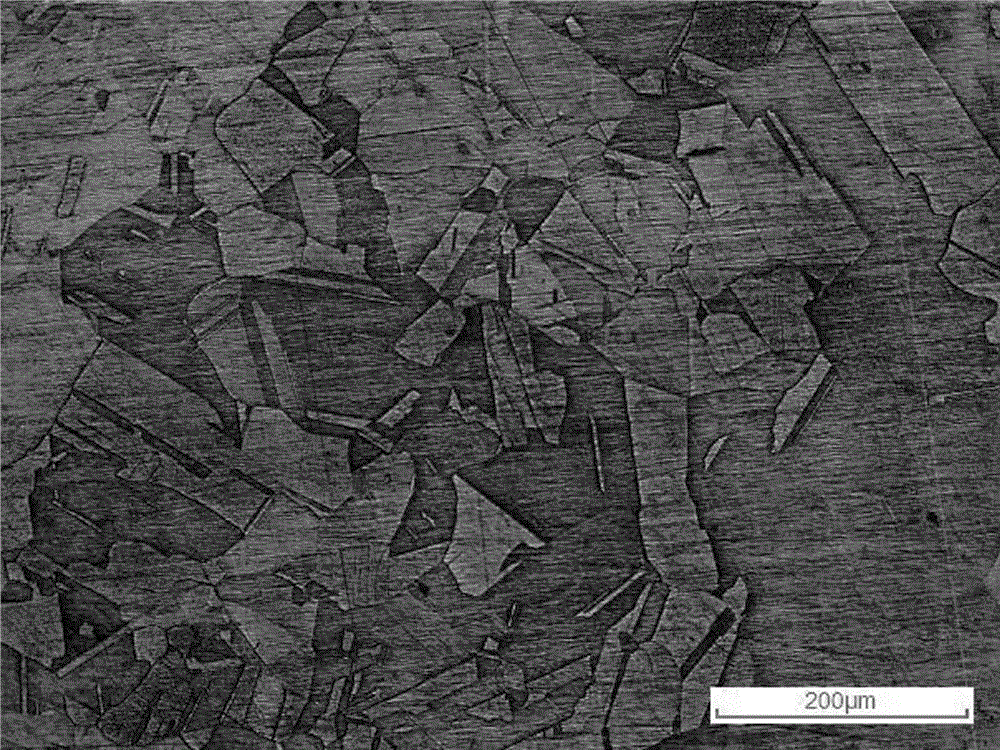

Embodiment 2

[0045] A method for preparing a large-scale high-purity copper planar target, comprising the following steps:

[0046] (1) Heat the cylindrical copper ingot (specification φ180 mm×360 mm, purity 99.999%, hardness HV40) to 650°C for 45 minutes, preheat the air hammer head to 300°C, and pull out the copper billet first Upsetting after lengthening, the final size is φ150 mm×450 mm;

[0047] (2) Continue to heat the copper ingot processed in step (1) for 35 minutes, and forge three times, each time forging 12 times, and the three forging directions (X, Y, Z directions) are perpendicular to each other, forging to a cuboid Copper forging billet, the size of cuboid copper forging billet is 80mm×210mm×830mm;

[0048] (3) Continuously heat the cuboid copper forging billet in step (2) at 350°C for 55 minutes, and cool it to room temperature in the air to realize the first annealing treatment of the copper forging billet;

[0049] (4) Hot-roll the cuboid copper forging billet after the...

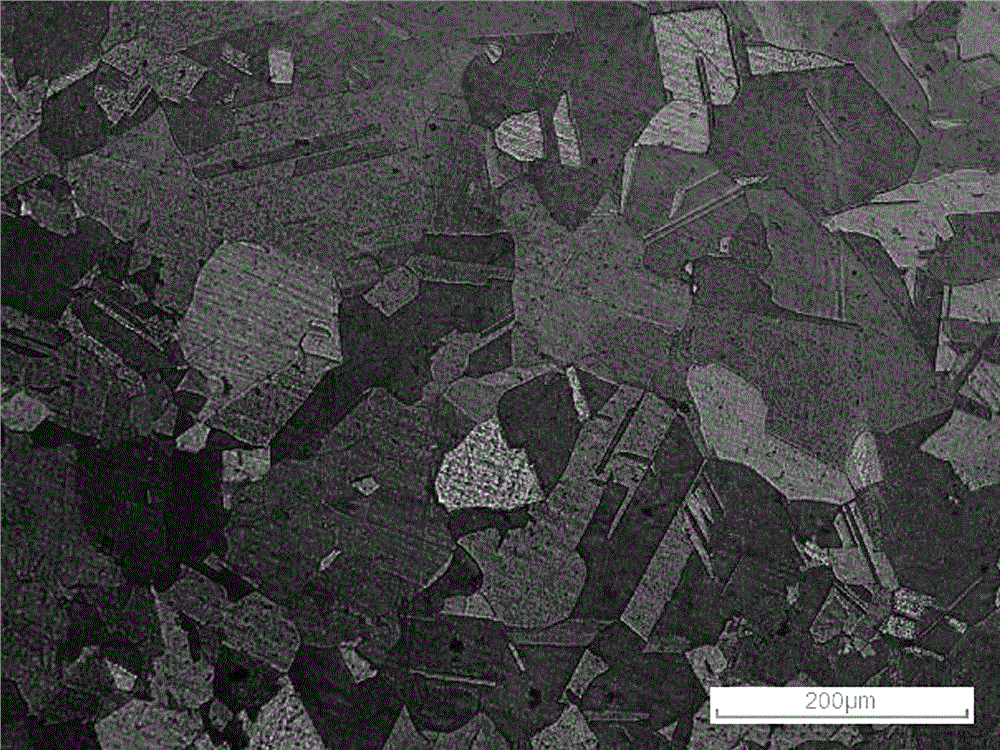

Embodiment 3

[0052] A method for preparing a large-scale high-purity copper planar target, comprising the following steps:

[0053] (1) Heat the cylindrical copper ingot blank (specification φ200 mm×400 mm, purity 99.99%, HV40) to 700°C for 40 minutes, preheat the hammer head of the air hammer to 350°C, and pull out the copper billet first After upsetting, the final size is φ130 mm×480 mm;

[0054] (2) Continue to heat the copper ingot processed in step (1) for 40 minutes, and forge three times, each forging 13 times, three forging directions (X, Y, Z directions) are perpendicular to each other, forging to a cuboid Copper forging billet, the size of cuboid copper forging billet is 70mm×220mm×820mm;

[0055] (3) Continuously heat the cuboid copper forging billet in step (2) at 380°C for 50 minutes, and cool it to room temperature in the air to realize the first annealing treatment of the copper forging billet;

[0056] (4) Remove the oxide layer on the surface of the cuboid copper forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com