Anti-microbial stoving varnish cylinder and making method thereof

A kind of baking paint, antibacterial and anti-corrosion technology, applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc., can solve the problem that the surface baking paint layer is easy to fall off, affect the quality of the contained materials, and the paint bucket is easy to breed bacteria, etc. Achieve excellent antibacterial ability, not easy to crack and fall off, and the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

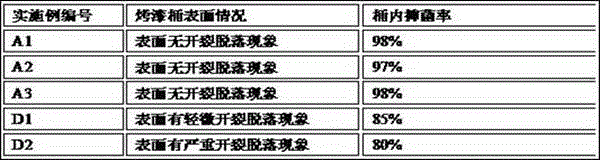

Embodiment 1

[0018] A method for preparing an antibacterial paint barrel, the preparation method comprising: cutting and welding iron sheets to obtain a barrel body M; pickling the barrel body M with pickling solution, and drying (drying temperature is 40°C, drying The time is 5min) and then set aside; stir and mix nanometer ferric oxide, styrene, methyl acrylate, ethyl acetate and glycerin to prepare antibacterial anticorrosion paint N, wherein 100g of nanometer ferric oxide, the styrene The consumption is 30g, the consumption of the methyl acrylate is 10g, the consumption of the ethyl acetate is 40g, the consumption of the glycerin is 1g, and the prepared antibacterial anticorrosion paint N is evenly coated on the barrel body M The surface of the bucket body M is put into a baking oven for baking (the baking temperature is 70°C, and the baking time is 15 minutes), and the antibacterial paint bucket A1 is obtained.

Embodiment 2

[0020] A method for preparing an antibacterial paint barrel, the preparation method comprising: cutting and welding iron sheets to obtain a barrel body M; pickling the barrel body M with pickling solution, and drying (drying temperature is 50°C, drying time is 10min) for later use; stir and mix nanometer ferric oxide, styrene, methyl acrylate, ethyl acetate and glycerin to prepare antibacterial anticorrosion paint N, wherein the amount of nanometer ferric oxide is 100g, and the benzene The consumption of ethylene is 40g, the consumption of the methyl acrylate is 15g, the consumption of the ethyl acetate is 50g, the consumption of the glycerin is 5g, and the prepared antibacterial anticorrosion paint N is uniformly coated on the barrel The surface of the body M, and put the bucket body M into a baking oven to bake (the baking temperature is 80°C, and the baking time is 20min), and the antibacterial paint bucket A2 is obtained.

Embodiment 3

[0022] A method for preparing an antibacterial paint barrel, the preparation method comprising: cutting and welding iron sheets to obtain a barrel body M; pickling the barrel body M with pickling solution, and drying (drying temperature is 45°C, drying time is 8min) and then set aside; stir and mix nanometer ferric oxide, styrene, methyl acrylate, ethyl acetate and glycerin to prepare antibacterial anticorrosion paint N, wherein the consumption of nanometer ferric oxide is 100g, the The consumption of styrene is 35g, and the consumption of described methyl acrylate is 12g, and the consumption of described ethyl acetate is 45g, and the consumption of described glycerin is 3g, and the antibacterial anticorrosion paint N that will make is evenly coated on described barrel surface of the body M, and put the bucket body M into a baking oven for baking (the baking temperature is 75°C, and the baking time is 18 minutes), to obtain the antibacterial paint bucket A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com