High-rigidity PP (polypropylene) expanded beads and energy-saving preparation method thereof

A technology of foaming beads and polypropylene, applied in the direction of coating, etc., can solve the problems of unfavorable material recycling, increased post-processing costs, and easy pollution, and achieves difficult peeling, good compatibility, and low steam pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

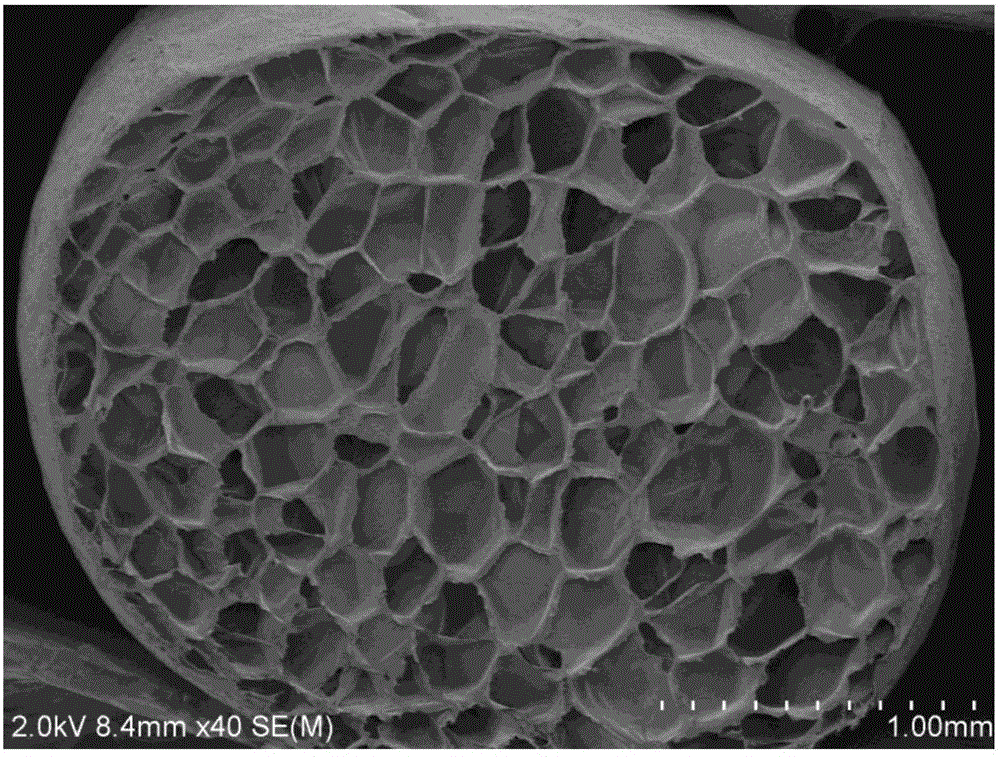

Image

Examples

Embodiment 1

[0023] A kind of high rigidity polypropylene foamed bead, comprise each component of following percentage by weight: High rigidity polypropylene 42 parts, the polypropylene of low molding pressure 58 parts, auxiliary agent 0.3 part; Wherein said high rigidity polypropylene is fusing point Polypropylene with a flexural modulus greater than 1.2MPa at a temperature greater than 140°C; the polypropylene with a low molding pressure is a polypropylene with a melting point less than 135°C. The melt index of rigid polypropylene and low molding pressure polypropylene blend is 5g / 10min.

[0024] Step 1: Mix high-rigidity polypropylene, polypropylene with low molding pressure and additives according to the weight ratio through an extruder, extrude, and draw wire, and then use pelletizing equipment to pelletize to form a modified polypropylene Microparticles, wherein the high-rigidity polypropylene is polypropylene with a melting point greater than 140°C, and the low-molding-pressure poly...

Embodiment 2

[0028] A kind of high-rigidity polypropylene foam beads, including the following components in weight percentage: 95 parts of high-rigidity polypropylene, 5 parts of polypropylene with low molding pressure, 2 parts of auxiliary agent; wherein the high-rigidity polypropylene is melting point Polypropylene with a flexural modulus greater than 1.2 MPa above 140°C; the polypropylene with low molding pressure is polypropylene with a melting point less than 130°C, and the melt index of the mixture of rigid polypropylene and polypropylene with low molding pressure is 15g / 10min .

[0029] Step 1: Mix high-rigidity polypropylene, polypropylene with low molding pressure and additives according to the weight ratio through an extruder, extrude, and draw wire, and then use pelletizing equipment to pelletize to form a modified polypropylene Microparticles, wherein the high-rigidity polypropylene is polypropylene with a melting point greater than 140°C, and the low-molding-pressure polypropy...

Embodiment 3

[0033] A kind of high rigidity polypropylene foamed bead, comprise each component of following percentage by weight: High rigidity polypropylene 70 parts, the polypropylene of low molding pressure 32 parts, auxiliary agent 1.2 parts; Wherein said high rigidity polypropylene is fusing point Polypropylene with a flexural modulus greater than 1.5 MPa at a temperature greater than 150°C; the polypropylene with a low molding pressure is a polypropylene with a melting point less than 130°C. High rigid polypropylene is propylene-butylene copolymerized polypropylene; low molding pressure polypropylene is ethylene-propylene-butylene terpolymerized polypropylene; the melt index of rigid polypropylene and low molding pressure polypropylene mixture is 8g / 10min.

[0034] Step 1: Mix high-rigidity polypropylene, polypropylene with low molding pressure and additives according to the weight ratio through an extruder, extrude, and draw wire, and then use pelletizing equipment to pelletize to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com