Heat dissipation composition as well as preparation method and application thereof

A composition and heat-dissipating paint technology, applied in chemical instruments and methods, adhesive additives, heat-exchange materials, etc., can solve the problems of emission frequency bandwidth, unsatisfactory heat-dissipating effect, etc., and achieve the effect of solving complex processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An embodiment of the present invention provides a heat dissipation composition, which includes: nano-silicon carbide and nano-titanium nitride, wherein the particle size of the nano-silicon carbide and nano-titanium nitride is between 10nm and 900nm.

[0025] It should be noted that for regular spherical nano-silicon carbide and nano-titanium nitride particles, the particle size refers to its diameter; for irregular particles, the particle size can refer to the definition of particle size in the prior art, the example There are three ways to define it: projection diameter, geometric equivalent diameter or physical equivalent diameter. Among them, projected diameter: refers to the particle diameter observed under a microscope; geometric equivalent diameter: the diameter of a spherical particle when it is equal to a certain geometric quantity of the particle; physical equivalent diameter: when it is equal to a certain physical quantity of the particle The diameter of the ...

Embodiment 2

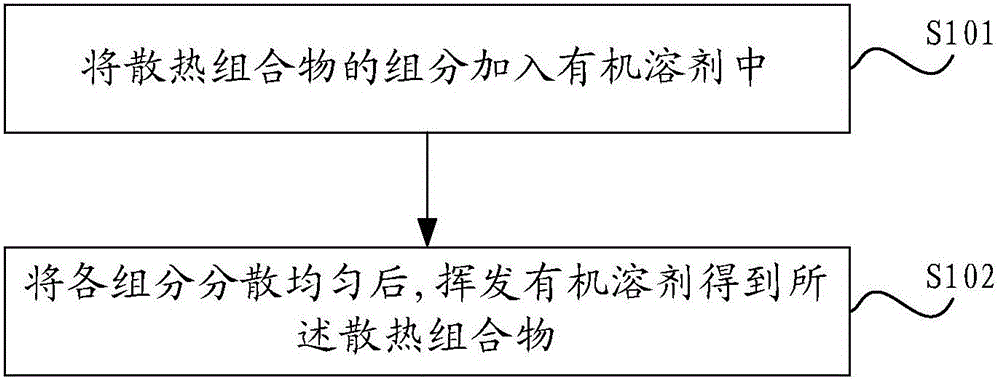

[0045] Embodiments of the present invention provide a method for preparing a heat dissipation composition, the method comprising the following steps:

[0046] S101: adding the components of the heat dissipation composition into the organic solvent.

[0047] Wherein, the components of the heat dissipation composition may include nano-silicon carbide and nano-titanium nitride, may also include nano-silicon carbide, nano-titanium nitride and nano-titanium dioxide, and may also include a coupling agent while including the aforementioned inorganic nanoparticles.

[0048] Each component is added in the organic solvent, can be divided into two kinds of situations:

[0049] One case is that for a heat dissipation composition that does not contain a coupling agent and only includes inorganic nanoparticles, it can be that all components are added together in an organic solvent, for example, adding nano-silicon carbide and nano-titanium nitride to an organic solvent together In, or nano...

Embodiment 3

[0080] The embodiment of the present invention provides the application of the heat dissipation composition described in the first embodiment in the preparation of heat dissipation paint, heat dissipation glue or heat dissipation plastic.

[0081] By filling the heat dissipation composition provided in Example 1 of the present invention as an inorganic filler into corresponding product raw materials (or matrix materials), corresponding composite materials can be obtained, namely heat dissipation paint, heat dissipation glue or heat dissipation plastic. When filling, the mass ratio of the heat dissipation composition to the matrix material can be set according to actual needs. In the preferred embodiment of the present invention, the mass fraction of the heat dissipation composition in the composite material ranges from 0.5% to 15%.

[0082] Specifically, the heat-dissipating coating is prepared by filling the heat-dissipating composition into a binder. Wherein, the adhesive he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com