Chemical nickel waste water treating method

A treatment method and chemical nickel technology are applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. Simple and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

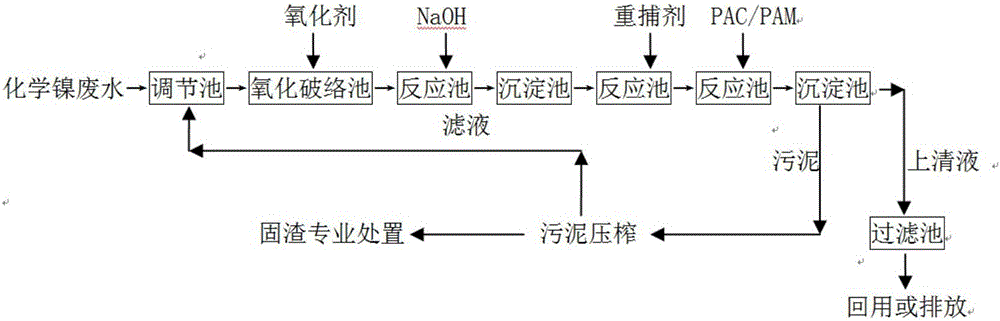

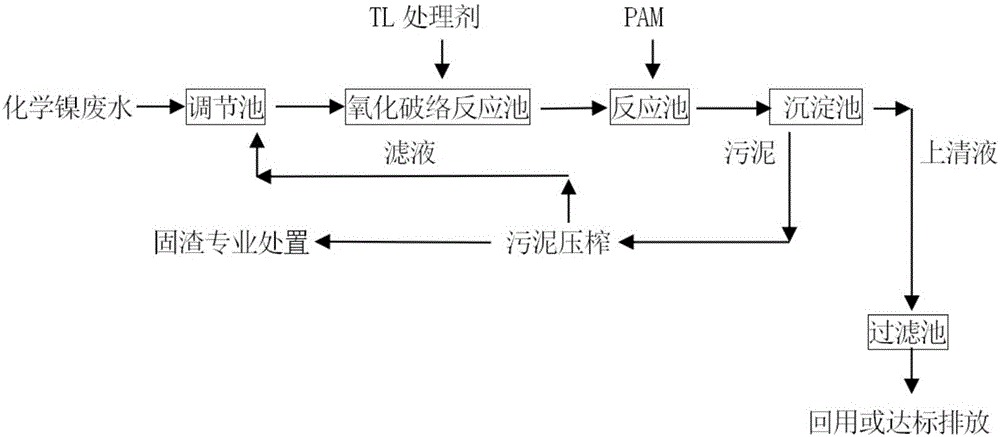

Method used

Image

Examples

Embodiment 1

[0018] Chongqing Haoli Electroplating Wastewater Treatment Station was put into operation in 2012, with a treatment capacity of 1,000 tons per day. Since the plastic electroplating contains chemical nickel wastewater, the chemical nickel wastewater is 50 tons / day, and the water quality of the chemical nickel wastewater in this station is: total nickel 80mg / L. The old technology was used at the beginning, the process is complicated and the process is long (1 regulating tank, 4 reaction tanks, and a sedimentation tank), there are many types of chemicals (5 kinds of chemicals), and the cost is high: the cost of treating one ton of chemical nickel wastewater is 20 The cost of water, electricity, labor, facilities and equipment is 10 yuan, and the nickel index of wastewater treatment cannot meet the standard stably. In October 2013, after our company took over the operation and management of the wastewater station, we solved this problem by applying the "TL chemical nickel wastewat...

Embodiment 2

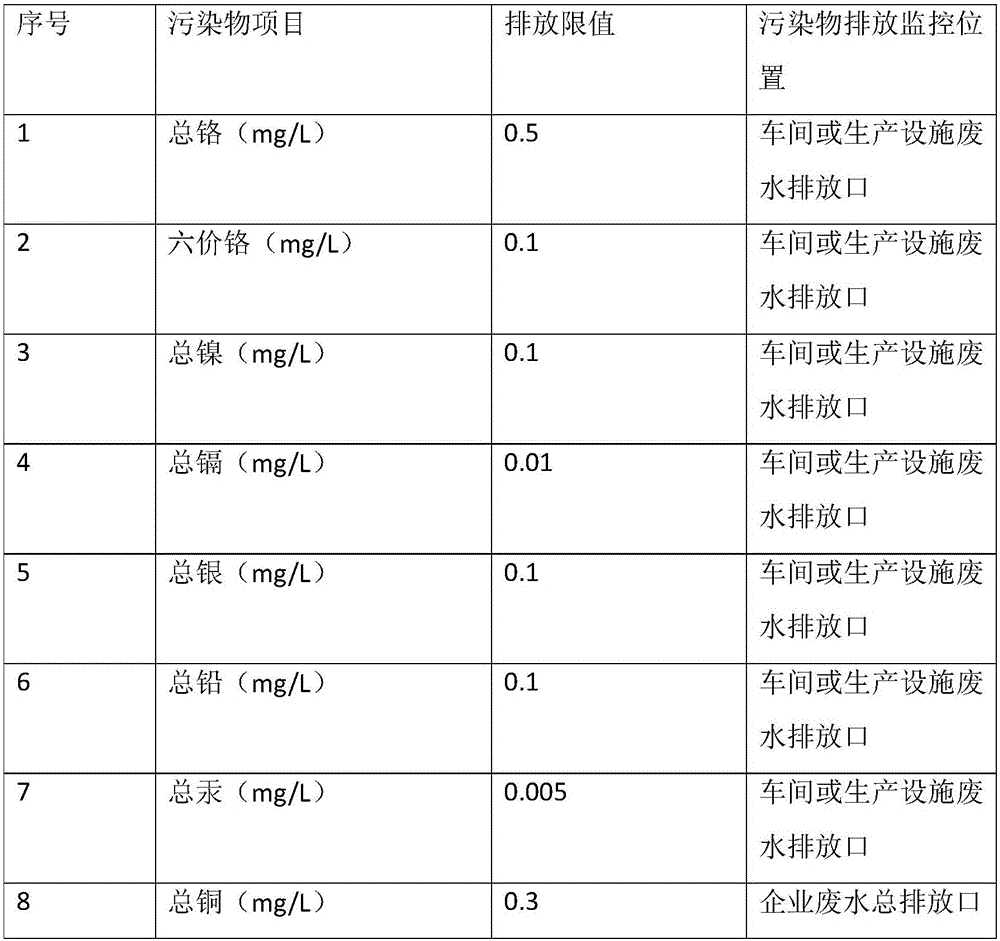

[0022] The invention was applied in March 2014, and gradually expanded to four units including Chongqing Qizhu Electroplating Wastewater Station, Chongqing Hengke Machinery Manufacturing Co., Ltd. (Electroplating Industrial Park), and Chongqing Zhilun Electroplating Co., Ltd. (Electroplating Industrial Park). Treatment of electroplating wastewater up to 3800m 3 As mentioned above, through repeated monitoring and testing by the municipal and district environmental protection departments, there has never been any phenomenon of excessive discharge, and the total nickel and total phosphorus can fully meet the discharge standards in Table 3, which is highly praised.

[0023] Chongqing Zhilun Electroplating Wastewater Treatment Station was put into operation in 2012, with a treatment capacity of 2,000 tons per day. Due to the complex water quality in the electroplating park, there are several chemical nickel plating production lines in the park, and the chemical nickel wastewater is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com