Novel Fenton fluidized bed and wastewater treatment method thereof

A fluidized bed and wastewater technology, applied in chemical instruments and methods, water treatment of special compounds, oxidized water/sewage treatment, etc., can solve the problems of complex equipment, low work efficiency, complicated process, etc., and achieve organic matter removal rate Improving and ensuring the quality of effluent water and the effect of reasonable process composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Comprehensive wastewater from a chemical enterprise, after necessary pretreatment, COD≤3000mg / L, pH 6.5~8.5, SS≤150mg / L, and characteristic pollutants chlorobenzenes≤50mg / L in wastewater need to be treated.

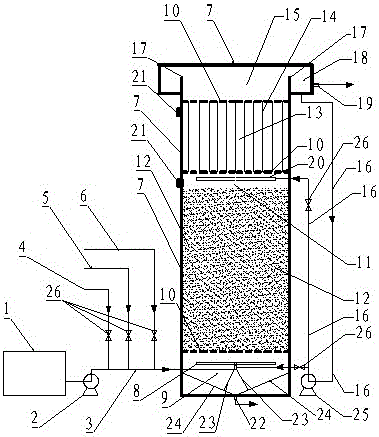

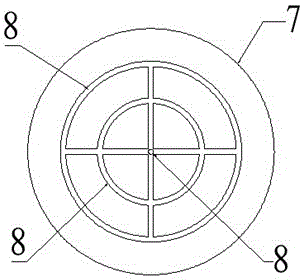

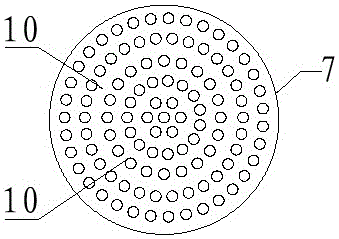

[0045] The advanced oxidation treatment is carried out by adopting the novel Fenton fluidized bed provided by the invention. Treatment device: a Fenton fluidized bed device, mainly including oxidation tower, sieve plate, filler A, filler B, Fenton oxidation zone, iron-carbon reaction zone, water inlet distribution zone, water outlet zone, water outlet tank, circulation Device, feed port, slag discharge port, sulfuric acid feed pipe, hydrogen peroxide feed pipe, ferrous sulfate feed pipe and raw water feed pipe; the oxidation tower is cylindrical, and three sieve plates divide the oxidation tower from bottom to top Inlet water distribution area, Fenton oxidation area, iron-carbon reaction area and water outlet area; filler A is added to the Fenton oxidation area, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com