Numerically controlled lathe for two-head processing of torsion rod and method for processing torsion rod through numerically controlled lathe

A CNC lathe and torsion bar technology, applied in metal processing, metal processing equipment, turning equipment, etc., can solve the problems of frequent changes in parameters such as length and diameter, inability to process both ends of a slender shaft, and large effective size, etc., to achieve The effects of reducing installation auxiliary time, shortening the effective distance, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention is further explained;

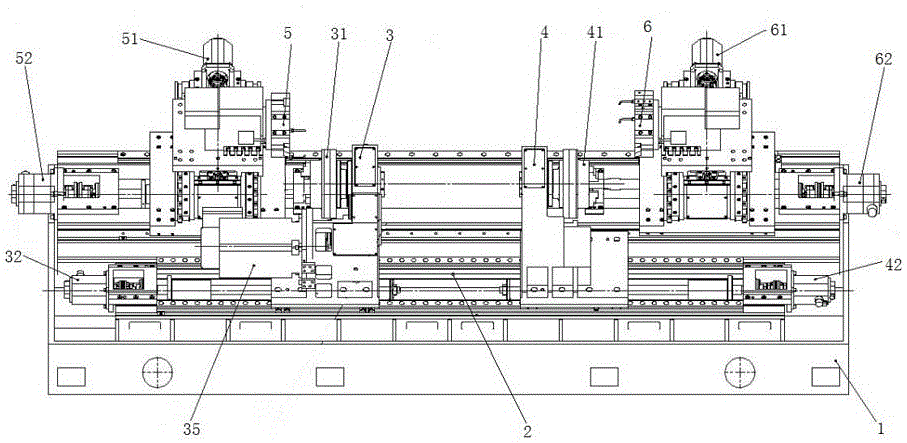

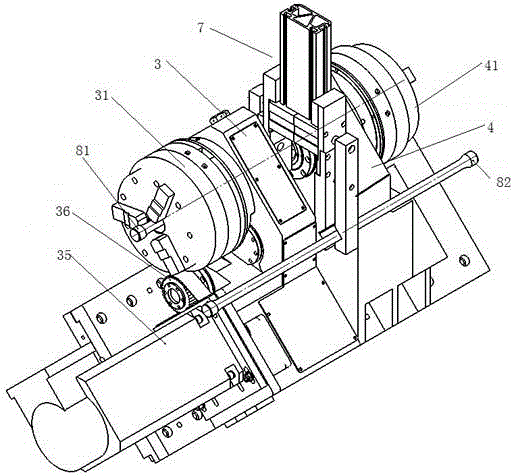

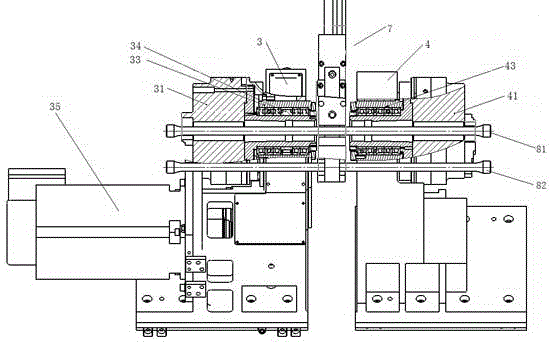

[0038] Such as Figure 1 to Figure 4 As shown, the CNC lathe used for torsion bar double-head processing includes a bed 1, a linear guide rail 2, a spindle box installed on the linear guide rail 2, a hydraulic tool rest for installing tools, and the spindle box includes a left spindle box 3 And right spindle box 4, described hydraulic tool rest comprises left hydraulic tool rest 5 and right hydraulic tool rest 6; The left pneumatic chuck 31 of front type is installed on described left spindle box 3, in described left spindle box 3 It is equipped with a precision spindle unit I33 and a precision gear transmission system 34 that drives the left pneumatic chuck 31 to rotate. The precision gear transmission system 34 is driven by a servo motor I35; the right spindle box 4 is equipped with a front-mounted right pneumatic chuck disc 41, the right spindle box 4 is provided with a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com