Preparation method of perylene diimide functionalization copper oxide nanocomposite

A technology of nanocomposite materials and perylene diimide, which is applied in the field of preparation of nanocomposite materials, and achieves the effects of mild reaction conditions, short reaction time and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ① Add 0.171 g copper chloride (CuCl 2 ∙ H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100 °C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60 °C for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

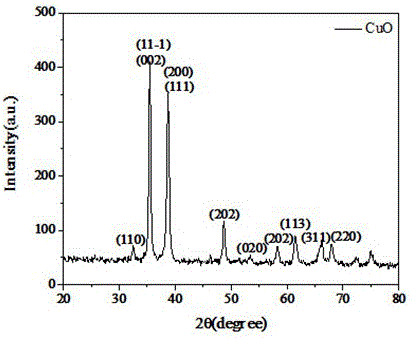

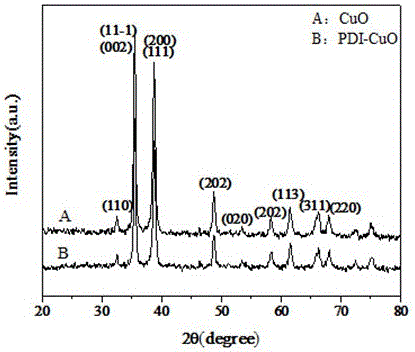

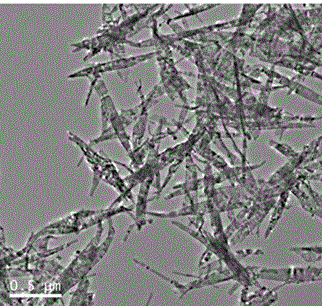

[0027] The resulting product was tested and the results were as follows: figure 1 , figure 2 , image 3 shown. From figure ...

Embodiment 2

[0029] ① Add 0.1425 g copper chloride (CuCl 2 ∙H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100 °C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60 °C for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

Embodiment 3

[0031] ① 0.21375 g copper chloride (CuCl 2 ∙ H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100°C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60 °C for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

[0032] On the basis of the above embodiments, the present invention needs to be explained as follows.

[0033] The raw material per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com