Processing technology of germ-remained polished rice with high yield of gamma-amino butyric acid

A processing technology, the technology of leaving germ rice, applied in the field of grain processing, can solve the problems of taste and nutrition can not be taken into account at the same time, low GABA content, etc., to achieve the effect of improving the quality of life and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

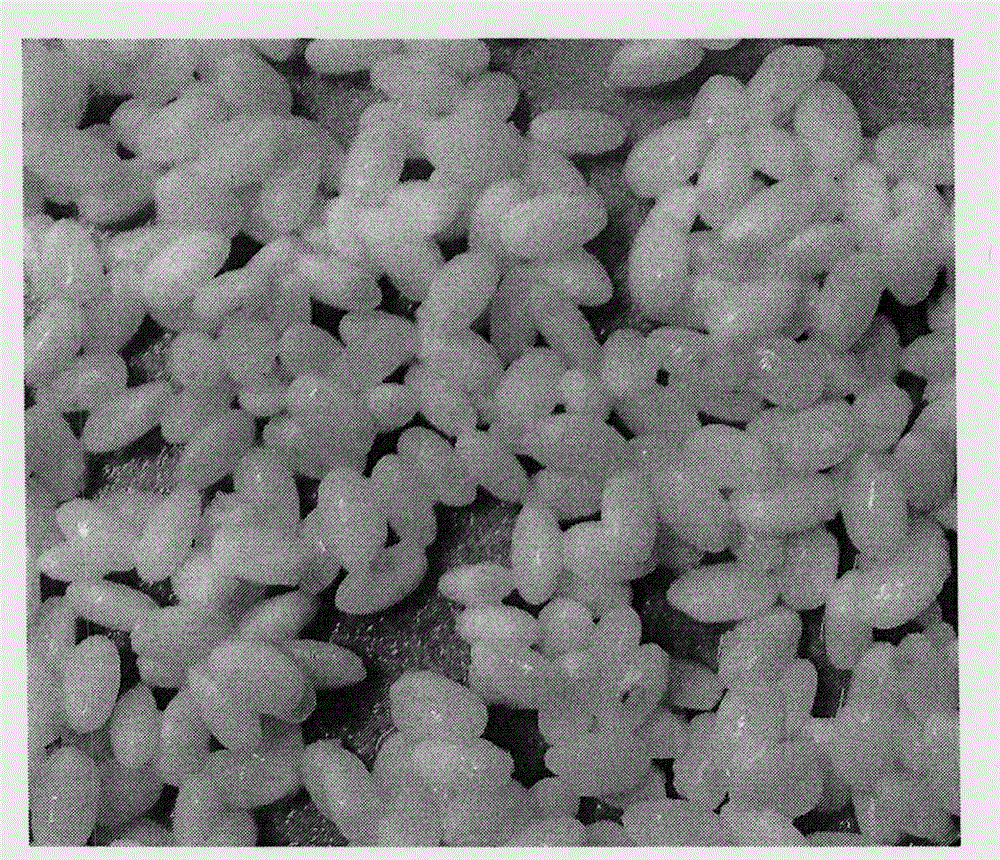

[0011] 1. Raw material screening: Raw material Z601 undergoes density screening and winnowing steps to select plump rice grains.

[0012] 2. Make brown rice: peel the screened rice grains to make clean brown rice.

[0013] 3. Grinding into polished rice: Use a small rice polishing machine to grind for 30 seconds to make polished rice with embryos.

[0014] 4. Germination: Transfer the polished rice with embryos into a germination machine, soak at a constant temperature of 29-32°C, and cultivate for 11-14 hours.

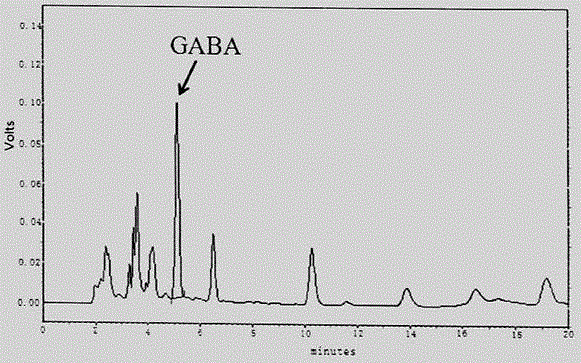

[0015] 5. Drying: After germination, put the germinated rice grains into an oven at 52-57°C to terminate the activity, and detect the GABA content by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com